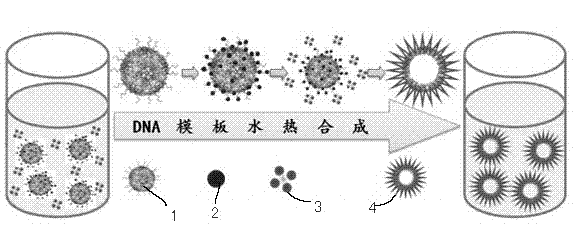

Hydroxyapatite hollow microsphere and preparation method thereof

A hydroxyapatite, hollow microsphere technology, applied in chemical instruments and methods, phosphorus compounds, nanotechnology for materials and surface science, etc., to achieve the effects of controllable size, convenient operation and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

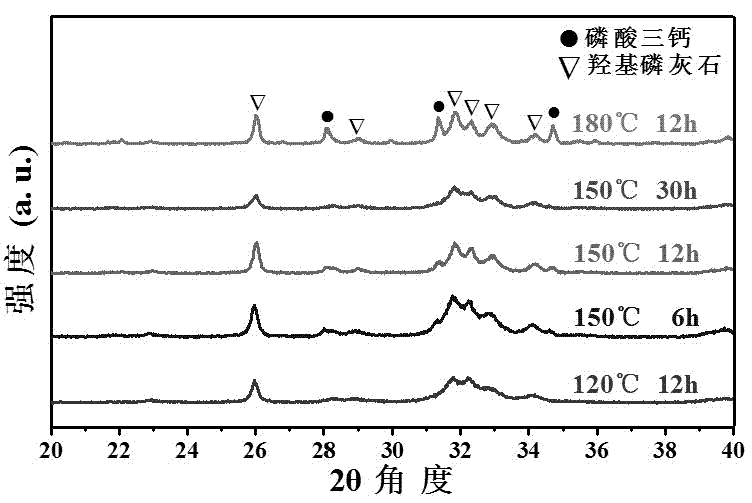

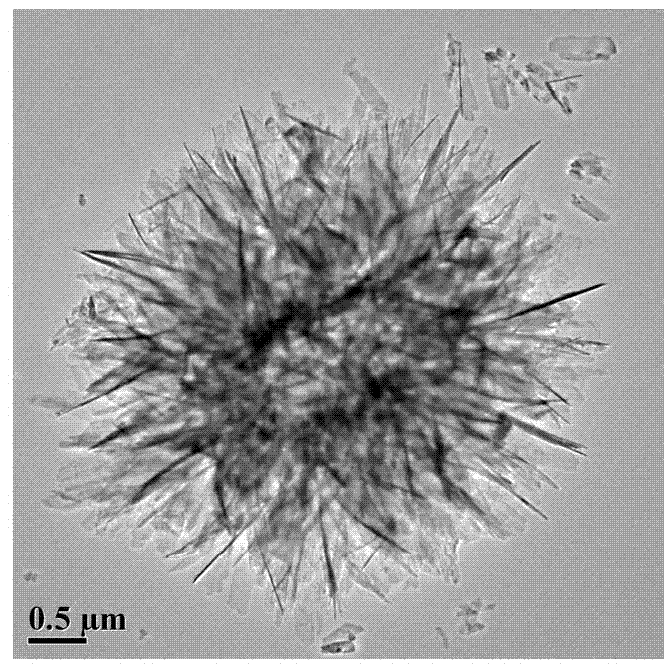

Embodiment 1

[0045] At room temperature, 1.791 g of Na 2 HPO 4 12H 2 O was dissolved in 250 ml of deionized water to form solution A, and 1.762 g of Ca(CH 3 COO) 2 ·H 2 O was dissolved in 100 mL of deionized water to form solution B. Add 0.020 g of protidine DNA to 60 ml of solution A, stir at room temperature to dissolve it completely, adjust the pH to 5 with 1 mol / liter of hydrochloric acid, then add 20 ml of solution B dropwise, and use 1 mol / liter of solution B in the process. liters of hydrochloric acid to adjust the pH to maintain it at around pH 5. After the addition is complete, transfer the mixed clear liquid into a Teflon liner (liner capacity 100 ml) and seal. Put the lining into the hydrothermal reaction jacket and put it into the holding furnace together with the jacket, and keep it warm at 150°C for 12 hours. After the reaction system was naturally cooled to room temperature, the product was taken out, and the product was separated by centrifugation. The separated prod...

Embodiment 2

[0047] At room temperature, 1.791 g of Na 2 HPO 4 12H 2 O was dissolved in 250 ml of deionized water to form solution A, and 1.762 g of Ca(CH 3 COO) 2 ·H 2 O was dissolved in 100 mL of deionized water to form solution B. Take 0.060 g of protidine DNA and add it to 60 ml of solution A, stir at room temperature to dissolve it completely, adjust the pH to 5 with 1 mol / liter of hydrochloric acid, then add 20 ml of solution B dropwise, and use 1 mol / liter of solution B in the process. liters of hydrochloric acid to adjust the pH to maintain it at around pH 5. After the addition is complete, transfer the mixed clear liquid into a Teflon liner (liner capacity 100 ml) and seal. Put the lining into the hydrothermal reaction jacket and put it into the holding furnace together with the jacket, and keep it warm at 150°C for 12 hours. After the reaction system was naturally cooled to room temperature, the product was taken out, and the product was separated by centrifugation. The se...

Embodiment 3

[0051] At room temperature, 1.791 g of Na 2 HPO 4 12H 2 O was dissolved in 250 ml of deionized water to form solution A, and 1.762 g of Ca(CH 3 COO) 2 ·H 2 O was dissolved in 100 mL of deionized water to form solution B. Add 0.100 g of protidine DNA to 60 ml of solution A, stir at room temperature to dissolve it completely, adjust the pH to 5 with 1 mol / L of hydrochloric acid, then add 20 ml of solution B dropwise, and use 1 mol / L of liters of hydrochloric acid to adjust the pH to maintain it at around pH 5. After the addition is complete, transfer the mixed clear liquid into a Teflon liner (liner capacity 100 ml) and seal. Put the lining into the hydrothermal reaction jacket and put it into the holding furnace together with the jacket, and keep it warm at 150°C for 12 hours. After the reaction system was naturally cooled to room temperature, the product was taken out, and the product was separated by centrifugation. The separated product was washed three times with dei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com