Synthesizing method of 2- butyl-1,2-benzisothiazoline-3-ketone

A technology of benzisothiazoline and a synthesis method, applied in directions such as organic chemistry, can solve the problems of low yield, long reaction steps, low product quality and the like, and achieve the effects of good product quality, low production cost, and less three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

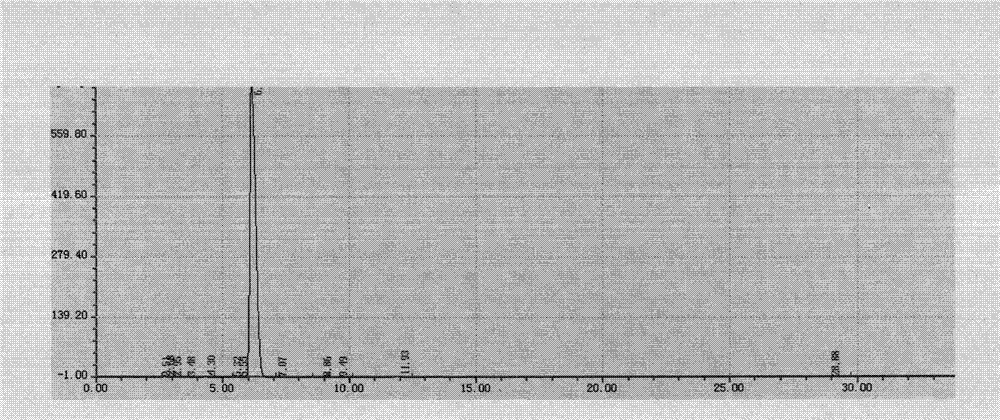

Image

Examples

Embodiment 1

[0017] Throw in 300g of 1,2-benzisothiazolin-3-one (BIT) with a solid content of 90%, 500g of water, 230g of 32% sodium hydroxide, heat up to 60-65°C, keep warm for 15min, fully dissolve, and cool down to 20- 25°C, filtered and dried to obtain 250 g of BIT sodium salt with a yield of 80%.

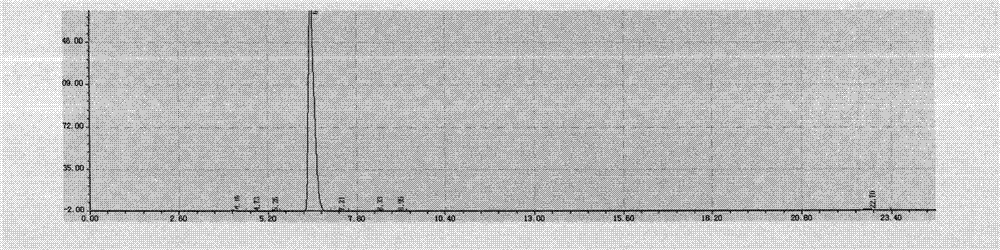

[0018] Put in 200g of BIT sodium salt, 395g of bromobutane, 75g of N,N-dimethylformamide, raise the temperature to 85-90°C, react for 5h, after the reaction is qualified, filter, distill the solvent under reduced pressure, and distill the crude product under vacuum to obtain 2-butyl Base-1,2-benzisothiazolin-3-ketone (HPLC>96%) (see specification attached figure 2 ), with a yield of about 74%.

Embodiment 2

[0020] Synthesis of BIT sodium salt is the same as Example 1.

[0021] Put in 200g of BIT sodium salt, 200g of chlorobutane, 100g of N,N-dimethylformamide, heat up to 75-80°C, and react for 15h. After the reaction is qualified, filter, distill the solvent under reduced pressure, and distill the crude product in vacuum to obtain 2-butyl 1,2-benzisothiazolin-3-one (HPLC>96%), the yield is about 75%.

Embodiment 3

[0023] Put in 99% 100g BIT, 91g anhydrous potassium carbonate, 300g chlorobutane, 150g N,N-dimethylformamide, heat up to 75-80°C, react for 5h, after the reaction is qualified, filter, distill the solvent under reduced pressure, and process to obtain 2-Butyl-1,2-benzisothiazolin-3-one (HPLC>96%), the yield is about 76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com