Assembly of membrane pump through 4-row cylindrical roller bearings

A technology of cylindrical roller bearings and diaphragm pumps, which is applied to components, pumps, pump components, etc. of pumping devices for elastic fluids, and can solve the problems of poor lubrication and clearance control, affecting the normal operation of equipment, Reciprocating motion failure and other problems, to achieve the effect of reliable operation, compact structure and rigidity of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Concrete scheme of the present invention is as follows:

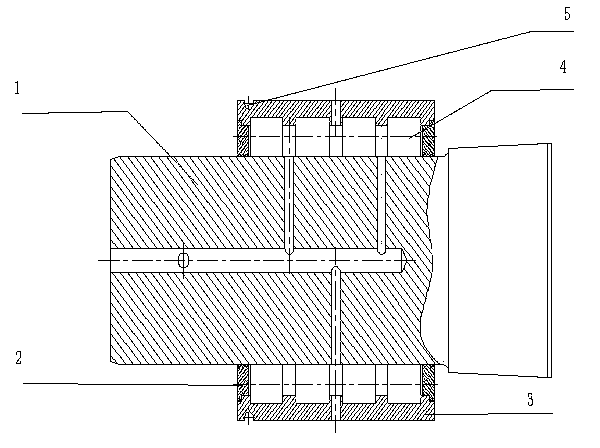

[0013] as attached figure 1 As shown, the diaphragm pump is assembled with a four-row cylindrical roller bearing, which is composed of a piston pin 1, a sealing ring 2, an outer ring 3 and a roller 4. The roller 4 is installed without a cage, the end surface of the outer ring 3 is embedded with the metal sealing ring 2, the outer surface of the outer ring 3 is provided with a stop ring groove 5 positioned with the small end, and the piston pin 1 is provided with an oil line.

[0014] The integrated structure of the outer ring 3 effectively ensures the rigidity of the complete set of components. During processing, the ribs are ground so that the ribs in contact with the roller 4 have a certain inclination, and logarithmic or arc correction is made to the outer circle generatrix of the roller 4 , to avoid stress concentration at the contact point and prevent damage caused by impact loads; the outer circular surfac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap