Powdery metallurgy balance block for crankshaft of gasoline engine and production method for powdery metallurgy balance block

A powder metallurgy and gasoline engine technology is applied to the powder metallurgy balance weight of the gasoline engine crankshaft and its production field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

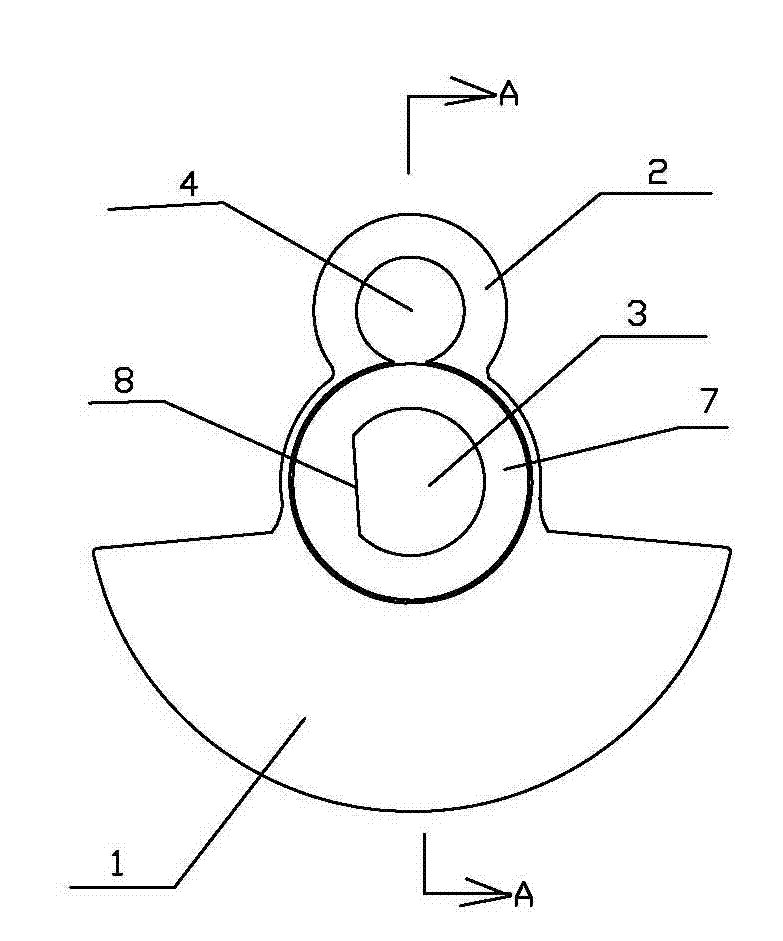

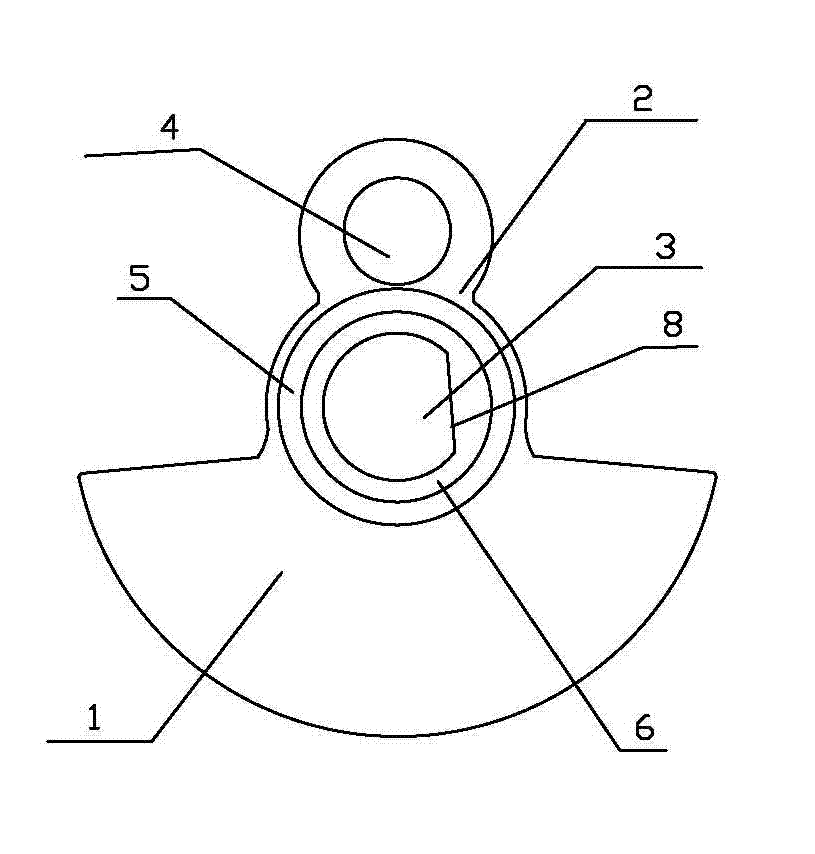

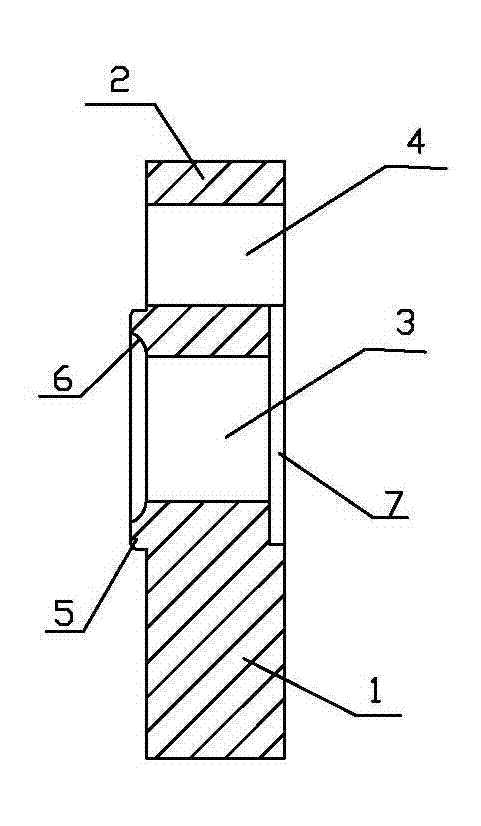

[0028] Implemented in our company, raw materials are weighed in batches of 100 pieces. produce as figure 1 , figure 2 , image 3 The shown gasoline engine crankshaft powder metallurgy balance weight.

[0029] The gasoline engine crankshaft powder metallurgy balance weight is characterized in that it includes a powder metallurgy semicircle block 1 and a powder metallurgy crank 2, and a fixing hole 3 at one end of the main shaft is provided at the connection part of the powder metallurgy semicircle block 1 and the powder metallurgy crank 2, and the powder The end of the metallurgical crank 2 is provided with a fixing hole 4 of the crank shaft, and the powder metallurgy semicircle fast 1 and the powder metallurgy crank 2 are symmetrical with respect to the fixing hole 3 at one end of the main shaft for weight balance; the fixing hole at one end of the main shaft One side of the inner wall of the 3 is a flat wall 8, and one end of the main shaft is inserted into the fixing hol...

Embodiment 2

[0045] The raw materials are weighed in batches of 100 pieces, including: copper powder 1%, nickel powder 3%, molybdenum powder 0.3%, graphite 0.7%, paraffin wax 0.6%, and the balance is iron powder.

[0046] Production steps (1), (2), (3) are the same as in Example 1.

[0047] In the production step (4), sinter the powder metallurgy balance block blank of the gasoline engine crankshaft: use a mesh belt furnace for sintering, the temperature in the pre-sintering stage is 780°C, last for 60 minutes, and the temperature in the alloying and sintering stage is 1120°C, last for 85 Minutes, cool down with the furnace.

[0048] In step (5), the qualified finished product is tested: After standard testing, its technical indicators are as follows: 100 pieces are all tested, and the test results are: 98 pieces have technical indicators as follows:

[0049] Average density: >7.52g / cm 3 ;

[0050] Average heat treatment hardness: HRC52;

[0051] Average tensile strength: >1050MPa;

[0...

Embodiment 3

[0055] The raw materials are weighed in batches of 100 pieces, including: copper powder 5%, nickel powder 1.5%, molybdenum powder 0.6%, graphite 0.8%, paraffin wax 1%, and the balance is iron powder.

[0056] Production steps (1), (2), (3) are the same as in Example 1.

[0057] In the production step (4), sinter the powder metallurgy balance block blank of the gasoline engine crankshaft: use a mesh belt furnace for sintering, the temperature in the pre-sintering stage is 850°C for 60 minutes, and the temperature in the alloying and sintering stage is 1120°C for 65 Minutes, cool down with the furnace.

[0058] In step (5), the qualified finished product is tested: After standard testing, its technical indicators are as follows: 100 pieces are all tested, and the test result is: 96 pieces reach:

[0059] Average density: >7.5g / cm 3 ;

[0060] Average heat treatment hardness: HRC56;

[0061] Average tensile strength: >1060MPa;

[0062] Dimensional accuracy grade: ≥IT 7 grade...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Average density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com