Glass cooling condenser

A condenser and glass technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of unable to condense and cool the gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

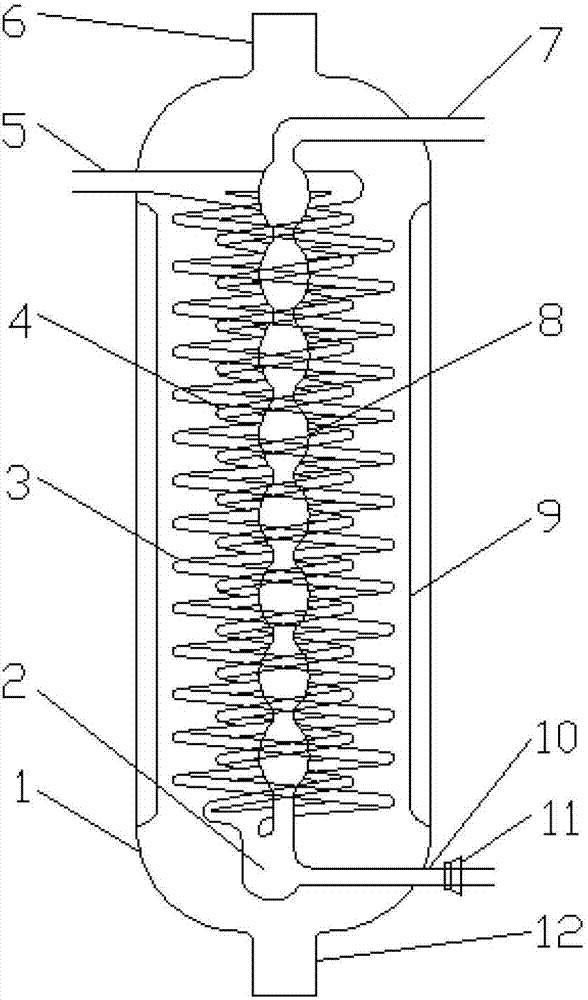

[0016] figure 1 It is a schematic diagram of the front structure of the glass cooling condenser in the embodiment of the present invention. Such as figure 1 As shown, the glass cooling condenser is made of glass and includes: a body 1 with a built-in cooling medium. The inner wall of the body 1 is provided with a vacuum interlayer 9 capable of heat insulation, and the upper and lower ends of the body 1 are respectively provided There is a cooling medium outlet 6 and a cooling medium inlet 12; the condenser tube placed in the cooling medium has two branches: a small diameter spiral tube 4 and a large diameter spiral tube 3. The condenser tube has upper and lower ends, and the upper end of the condenser tube extends Outlet body 1, the upper opening is used as the air inlet 5 for the gas that needs to be cooled and condensed, the lower end of the condenser tube is connected to the liquid storage tube; the cooling gas output tube 8, the upper end of the opening extends out of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com