Method for determining porosity of polymer porous plate-type membrane material

A polymer and porous plate technology, applied in suspension and porous material analysis, measurement devices, permeability/surface area analysis, etc., can solve the problems of inaccurate results, affecting membranes, errors, etc., and achieve simple process methods and testing equipment Simple, short operation time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

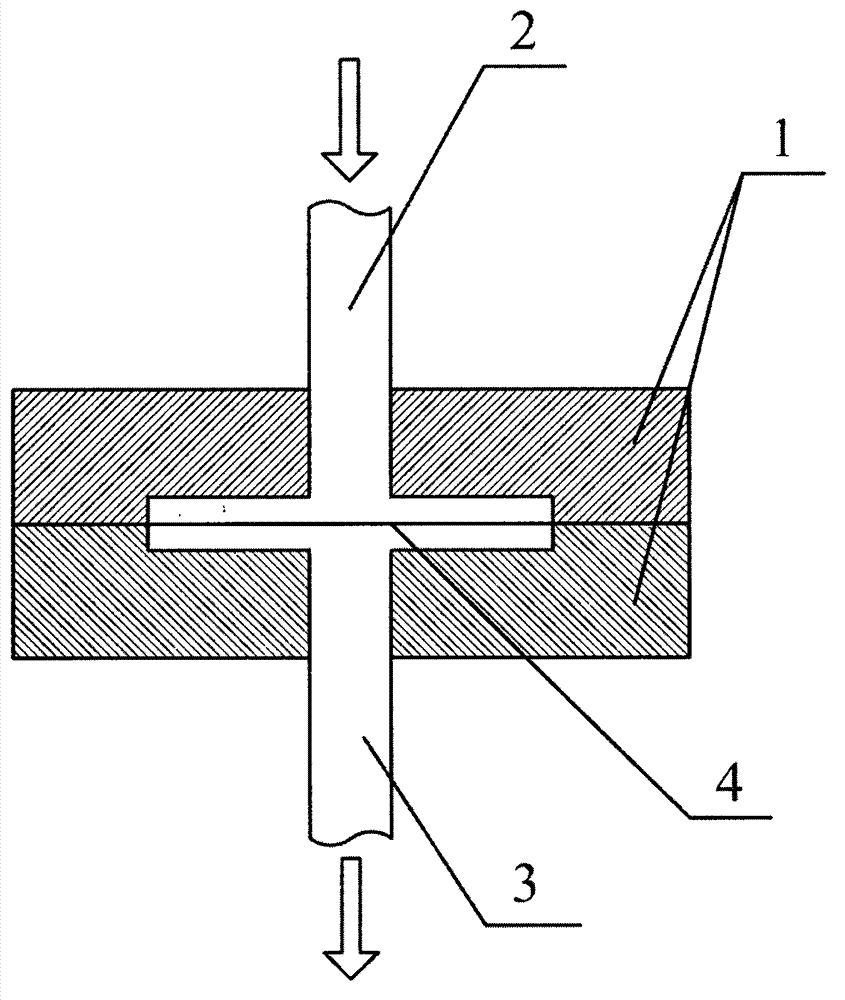

[0028] Take the polyvinyl butyral porous plate membrane, place it in the plate membrane infiltration module, adjust the water pressure to 0.01MPa, and make the water pass through the membrane for 60min, so that the water can completely fill the pores of the membrane.

[0029] Take out the polyvinyl butyral porous plate membrane from the membrane soaking module, hang it on the hook of the density balance, immerse it in water, and measure the quality of the membrane to be tested as W a = 0.0422g.

[0030] Take out the polyvinyl butyral porous plate membrane from the water, wipe off the water on the surface of the membrane with a cloth saturated with water, and weigh the mass W of the polyvinyl butyral porous plate membrane in the air with a balance b = 0.2930 g.

[0031] Dry the polyvinyl butyral porous plate membrane in the air until the mass difference between the two times of drying is 0.0002g, and weigh the mass W of the polyvinyl butyral porous plate membrane in the air. ...

Embodiment 2

[0034] Take the polyvinylidene fluoride porous plate membrane, place it in the plate membrane infiltration module, adjust the water pressure to 0.1MPa, and make the water pass through the membrane for 40min, so that the water can completely fill the pores of the membrane.

[0035] Take out the polyvinylidene fluoride porous plate membrane from the membrane soaking module, hang it on the hook of the density balance, and immerse it in water, and measure the mass of the membrane to be tested as W a = 0.0571 g.

[0036] Take the polyvinylidene fluoride porous plate membrane out of the water, wipe off the water on the surface of the membrane with a cloth saturated with water, and weigh the mass W of the polyvinylidene fluoride porous plate membrane in the air with a balance b = 0.3573g.

[0037] Dry the polyvinylidene fluoride porous plate membrane in the air until the mass difference between the two times of drying is 0.0001g, and weigh the mass W of the polyvinylidene fluoride p...

Embodiment 3

[0040] Take the polytetrafluoroethylene porous plate membrane, place it in the plate membrane infiltration module, adjust the water pressure to 0.2MPa, and make the water pass through the membrane for 20min, so that the water can completely fill the pores of the membrane.

[0041] Take the polytetrafluoroethylene porous plate membrane out of the membrane soaking module, hang it on the hook of the density balance, and immerse it in water, and measure the mass of the membrane to be tested as W a = 0.0525g.

[0042] Take the polytetrafluoroethylene porous plate membrane out of the water, wipe off the water on the surface of the membrane with a cloth saturated with water, and weigh the mass W of the polytetrafluoroethylene porous plate membrane in the air with a balance b = 0.3033g.

[0043] Dry the polytetrafluoroethylene porous plate membrane in the air until the mass difference after two times of drying is 0.0004g, weigh the mass W of the polytetrafluoroethylene porous plate mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com