System for measuring solution concentration by using perturbation method

A solution concentration and measurement system technology, applied in the field of control systems, can solve problems such as limiting the measurement range and need to be improved, and achieve the effects of high measurement reliability, simple structure, and low environmental requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

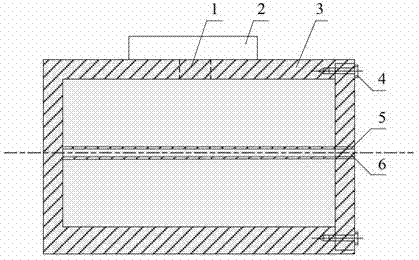

[0018] For more detailed content of the microwave resonant cavity sensor used in the present invention, please refer to the previous patent application 201210009379.3. Combine now figure 1 A brief description of the sensor, the sensor includes a resonant cavity 3; a glass tube 5 is arranged in the middle of the resonant cavity 3, and the inner area 6 of the glass tube is used to place the solution to be measured; a circular hole is opened in the center of the side wall of the resonant cavity 3 1. The resonant cavity is coupled with the rectangular waveguide through the round hole to transmit microwave signals; the positioning screw 4 is used to fix the top cover and the cavity body 3 .

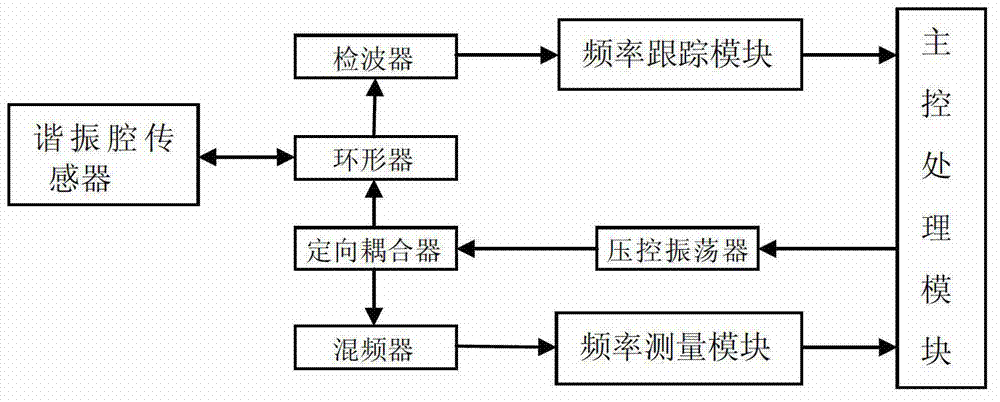

[0019] The microwave signal generated by the microwave source is introduced into the waveguide through the circulator, and then coupled to the resonant cavity through the waveguide transmission. The reflected signal of the resonant cavity is introduced into the detector through the circulator,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com