Detachable flexible single jaw

A technology of soft claws and soft claws, which is applied in the field of detachable soft claws and single claws, can solve the problems of difficult to determine the radial position, affect the processing accuracy, scrapping and other problems, and achieve the effect of adjustable size, strong rigidity and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

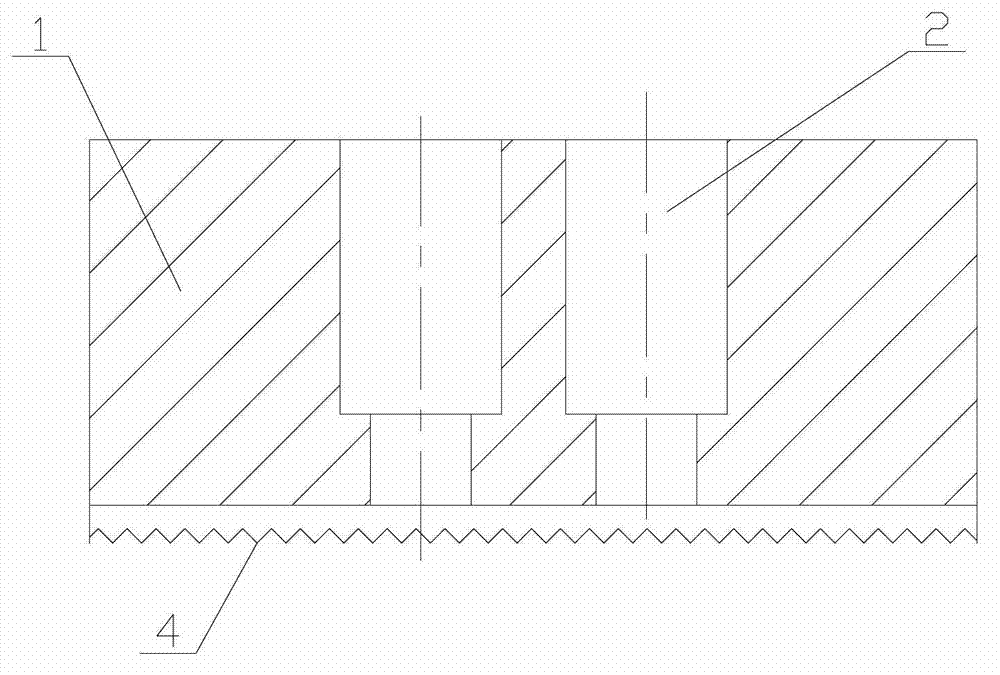

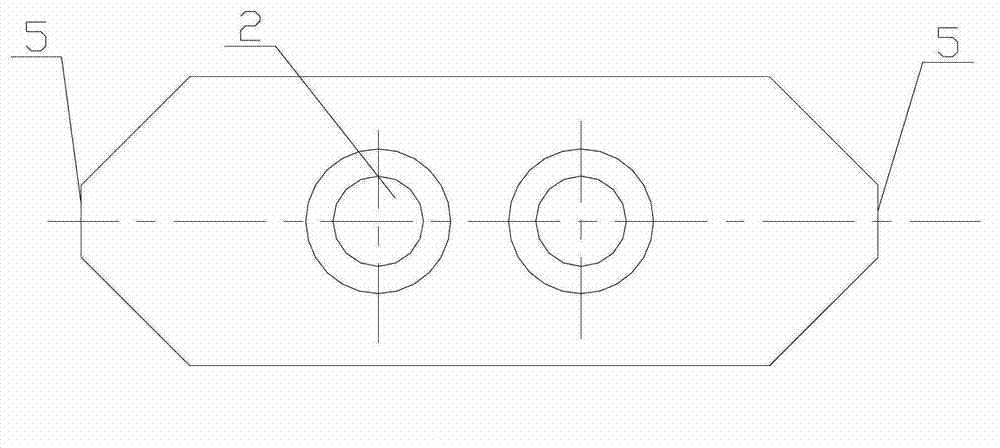

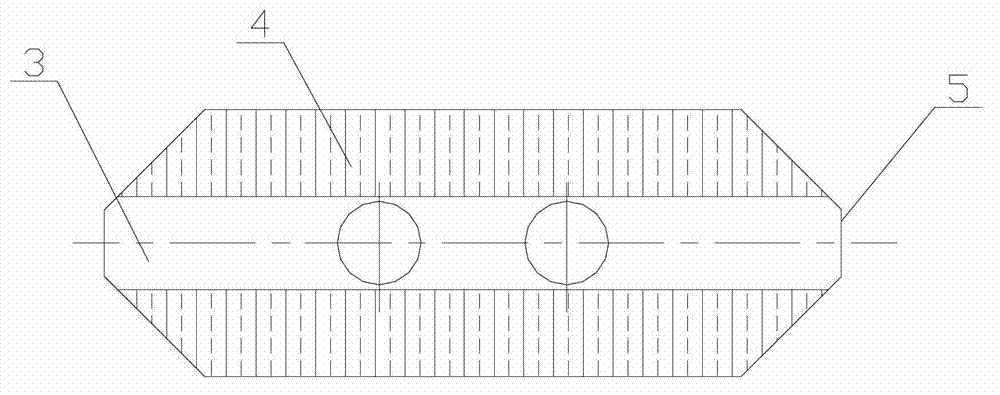

[0020] like Figure 1~3 As shown, in this embodiment, a detachable soft claw single claw according to the present invention has two countersunk bolt holes in the middle of the soft claw 1 as mounting holes 2 for connecting the soft claw 1 with the bump , the bottom of the soft claw 1 is provided with a bump installation groove 3, the bump installation groove 3 runs through the bottom of the soft claw 1, the bump is placed in the bump installation groove 3, and the bump is connected to the soft claw 1 by a hexagon socket bolt , the two sides of the bump installation groove 3 are provided with positioning grooves 4, the positioning grooves 4 are corrugated protrusions perpendicular to the bump installation groove 3, and the positioning grooves 4 are covered with the bottom of the soft claw 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com