Rapid pipe cutting mechanism capable of moving compositely

A compound motion and fast technology, applied in the direction of pipe shearing device, shearing device, metal processing machinery parts, etc., can solve the problems of complex structure, high power consumption, long stroke of the coiling mechanism, etc., to achieve easy automatic cutting production, good Cutting effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

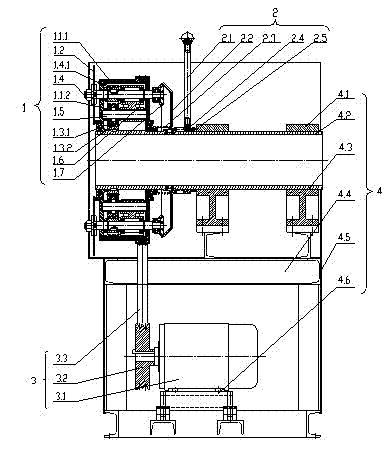

[0028] The present invention will be described in further detail below in conjunction with the embodiments of the accompanying drawings.

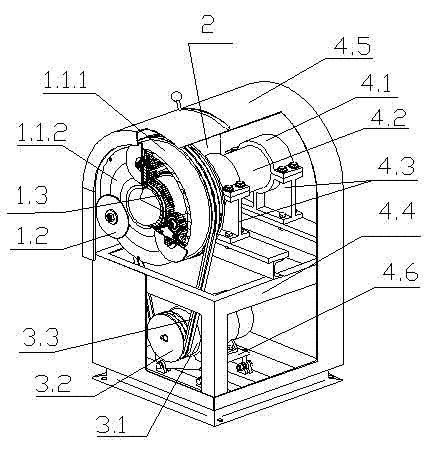

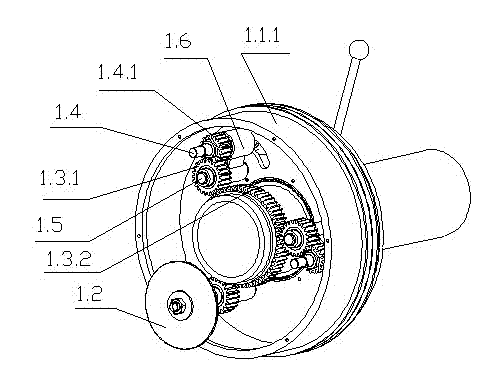

[0029] see Figure 1 to Figure 6 . A composite motion fast pipe cutting mechanism, comprising a rotary blade 1.2, a blade rotating shaft 1.4, a blade rotating shaft drive mechanism and a pipe clamping mechanism, characterized in that: it also includes a galaxy gear train 1.3, the pipe clamping mechanism and the planetary gear train The sun gear 1.3.2 is coaxial, the blade wheel 1.4.1 on the blade shaft 1.4 meshes with the planetary gear 1.3.1 of the planetary gear system, and the two barrels of the double-tube rocker arm 1.6 are respectively sleeved on the blade shaft 1.4 and the planetary shaft 1.5 ; The planetary gear shaft 1.5 is fixed on the rotary gearbox (consisting of the gearbox shell 1.1.1 and the gearbox cover 1.1.2).

[0030] Due to the use of the galaxy gear train 1.3, and the connection of the blade wheel 1.4.1 with the planet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com