Air-source and solar compound heating type crude oil storage and transportation system

A composite heating and air source heat pump technology, applied in solar thermal power generation, solar thermal devices, fluid heaters, etc., can solve problems such as energy waste in crude oil storage and transportation systems, high requirements for low temperature heat source stability, and unstable system operation. , to achieve the effect of reducing viscosity and drag, good economic and social benefits, reducing consumption and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

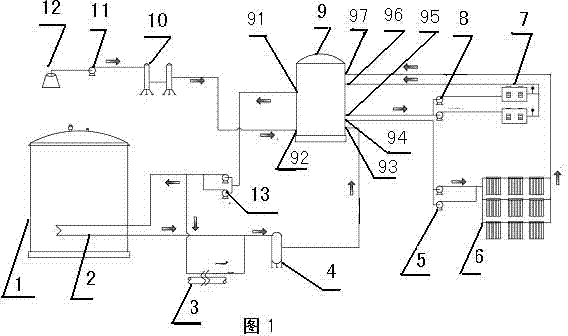

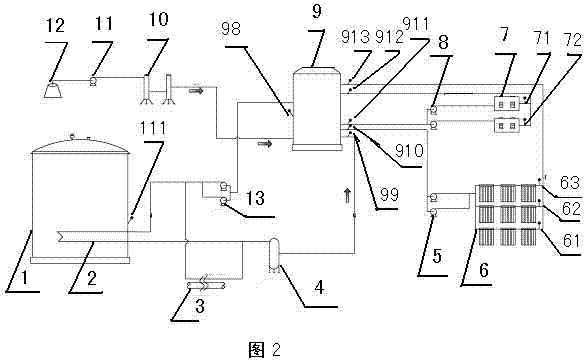

[0029] This air source and solar energy composite heating crude oil storage and transportation system such as figure 1 , figure 2 As shown, the air source and solar energy composite heating crude oil storage and transportation system mainly includes solar collector, air source heat pump unit, water treatment device, hot water storage tank, oil storage tank, hot water lifting pump, iron removal device and control device. A hot water outlet and a water supply outlet are arranged on the tank wall on one side of the hot water storage tank, and a return water outlet, a solar collector water outlet, an air source heat pump unit water outlet, and an air outlet are arranged on the other side of the tank wall. The hot water inlet of the source heat pump unit and the hot water inlet of the solar collector, the hot water outlet is placed at 3 / 5 of the height of the hot water storage tank, and the hot water circulation pump is connected to the heating coil and one end of the gath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com