Method for preheating coal as fired by hot exhaust gas and regenerating active coke by hot exhaust gas

A technology of activated coke regeneration and hot waste gas, which is applied in the direction of combustible gas heating coke ovens, coke ovens, and energy input, etc., can solve the problems of inability to carry out continuous production, no waste gas export, recycling, purification and utilization, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A specific embodiment of the method for preheating coal with hot waste gas into the furnace and regenerating active coke according to the present invention is mainly introduced in detail in the following parts 3 and 5.

[0025] The second part of coal dehydration

[0026] At present, most of the coking ovens on the market adopt intermittent coking, and the coal into the furnace is wet coal, so energy consumption increases the cost of coking. Dehydration of the coal entering the coal pyrolysis furnace is performed in advance to save energy. The effect of reducing consumption.

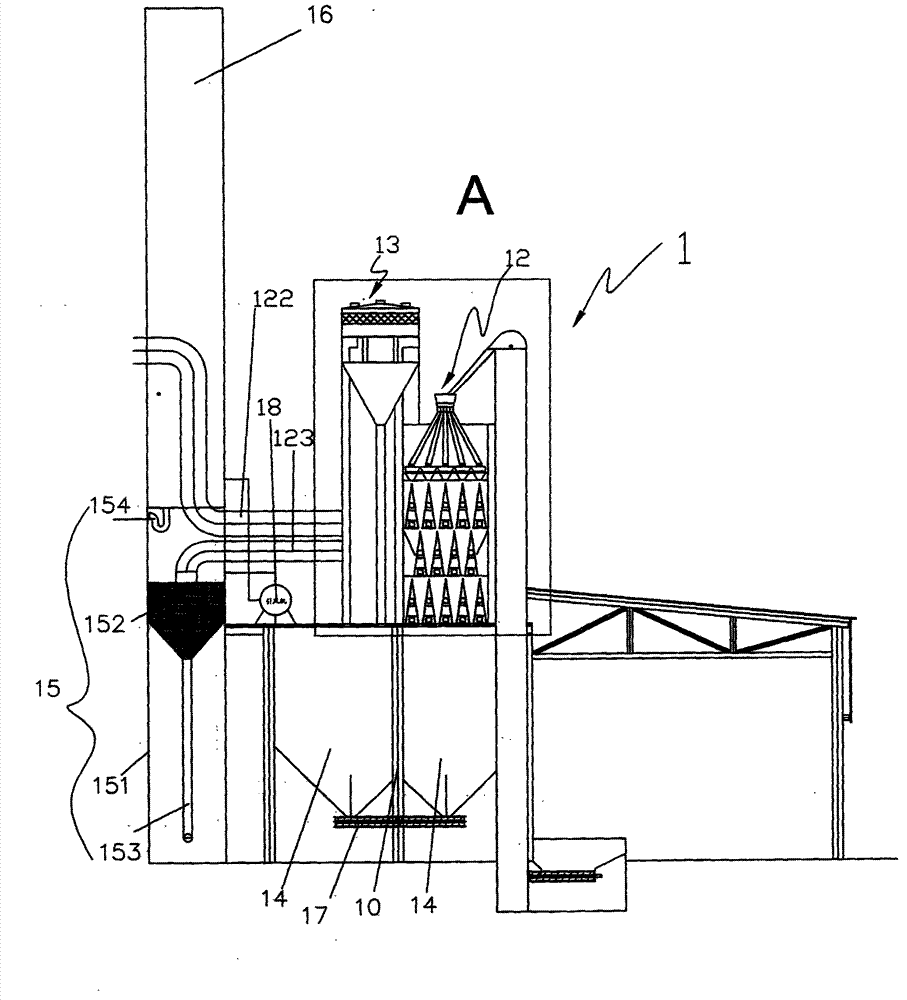

[0027] like figure 1 As shown: the furnace coal dehydration device 1 includes a dehydration frame body 10, a bucket elevator 11, a waste gas dehydrator 12, a coal dust filter 13, a silo 14, a dust collector 15, a chimney 16, and a furnace coal conveyor 17.

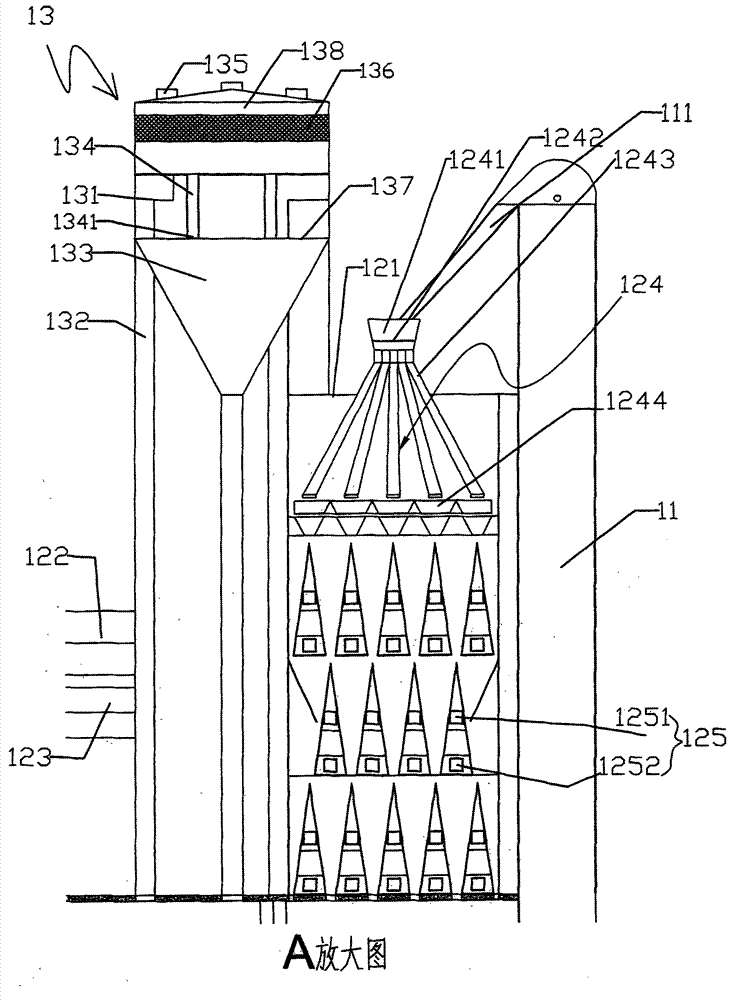

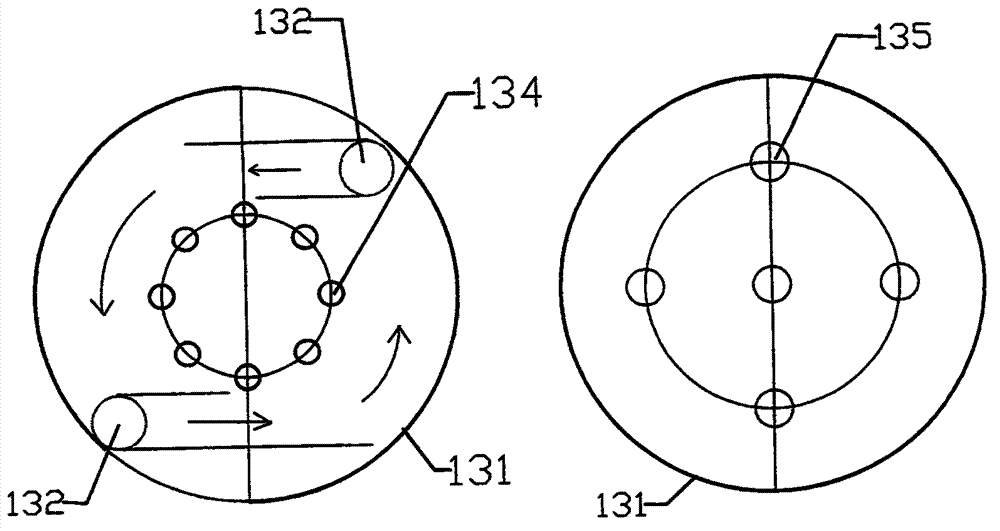

[0028] like figure 1 , figure 2 As shown: the waste gas dehydrator 12 includes a dehydrator shell 121, a main inlet pipe 122 for hot wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com