Method and device of improving online monitoring accuracy of engine oil metal abrasive particles

A technology of metal abrasive particles and engine oil, which is applied in the direction of analyzing materials and instruments, and can solve the problems of affecting the normal operation of the engine, single device method, and misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

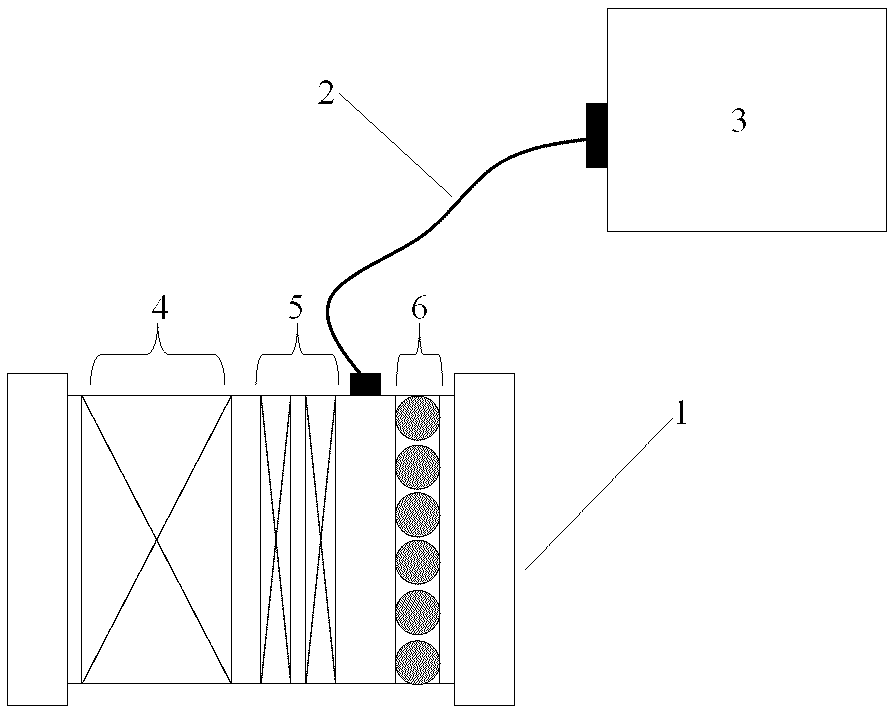

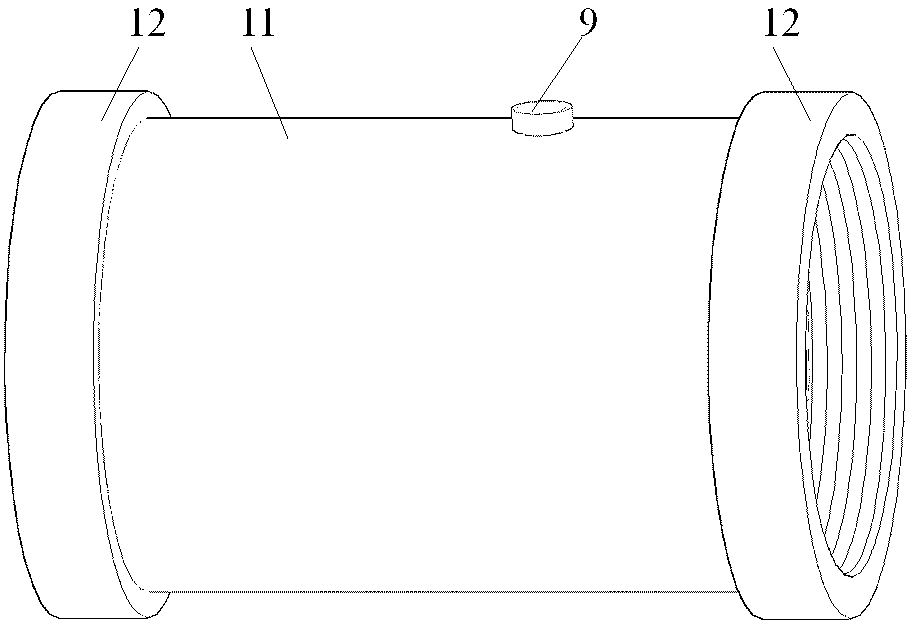

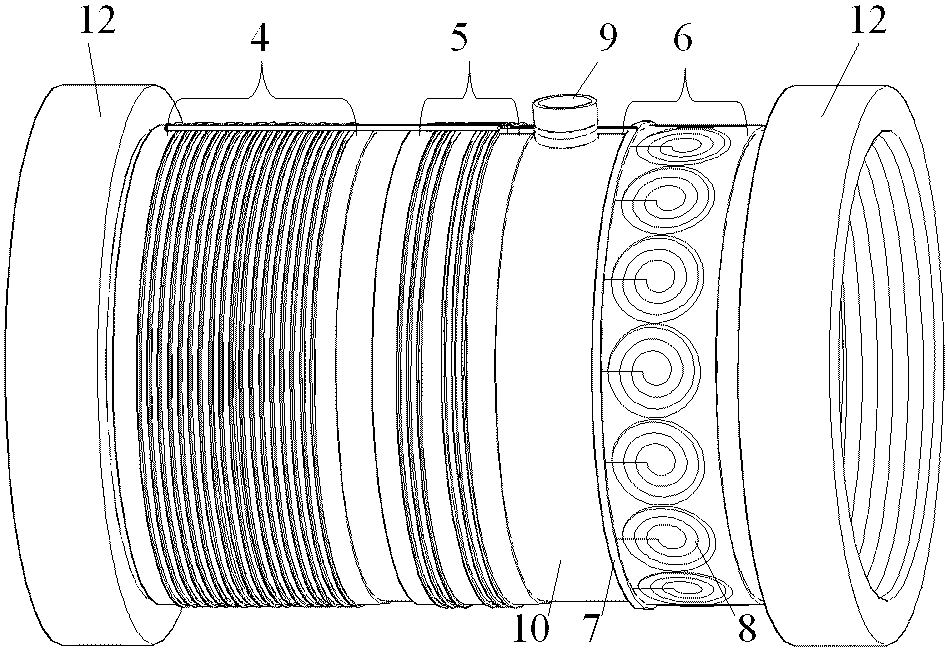

[0034] exist figure 1 , figure 2 , image 3In the first embodiment shown, a method and device for improving the online monitoring accuracy of engine oil metal abrasive particles, the device consists of a round tube electromagnetic integrated sensor (1), a sensor cable (2), and an electromagnetic detector (3) Composition; the round tube type electromagnetic integrated sensor (1) is composed of a sheath-type absolute electromagnetic detection coil (4), a sheath-type differential electromagnetic detection coil group (5), an annular flexible array electromagnetic probe group (6), and a sensor output multi-core A socket (9), a non-metallic round tube (10), a metal shielding tube (11), and two metal adapter rings (12); the jacket-type absolute electromagnetic detection coil (4), the jacket-type differential electromagnetic detection The coil group (5) and the annular flexible array electromagnetic probe group (6) are respectively fixed and wound between the outer surface of the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com