Liquid-cooled motor controller

A motor controller and liquid cooling technology, which is applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of poor heat conduction effect and complicated processing technology, and achieve the effects of reducing processing workload, simple processing technology and reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

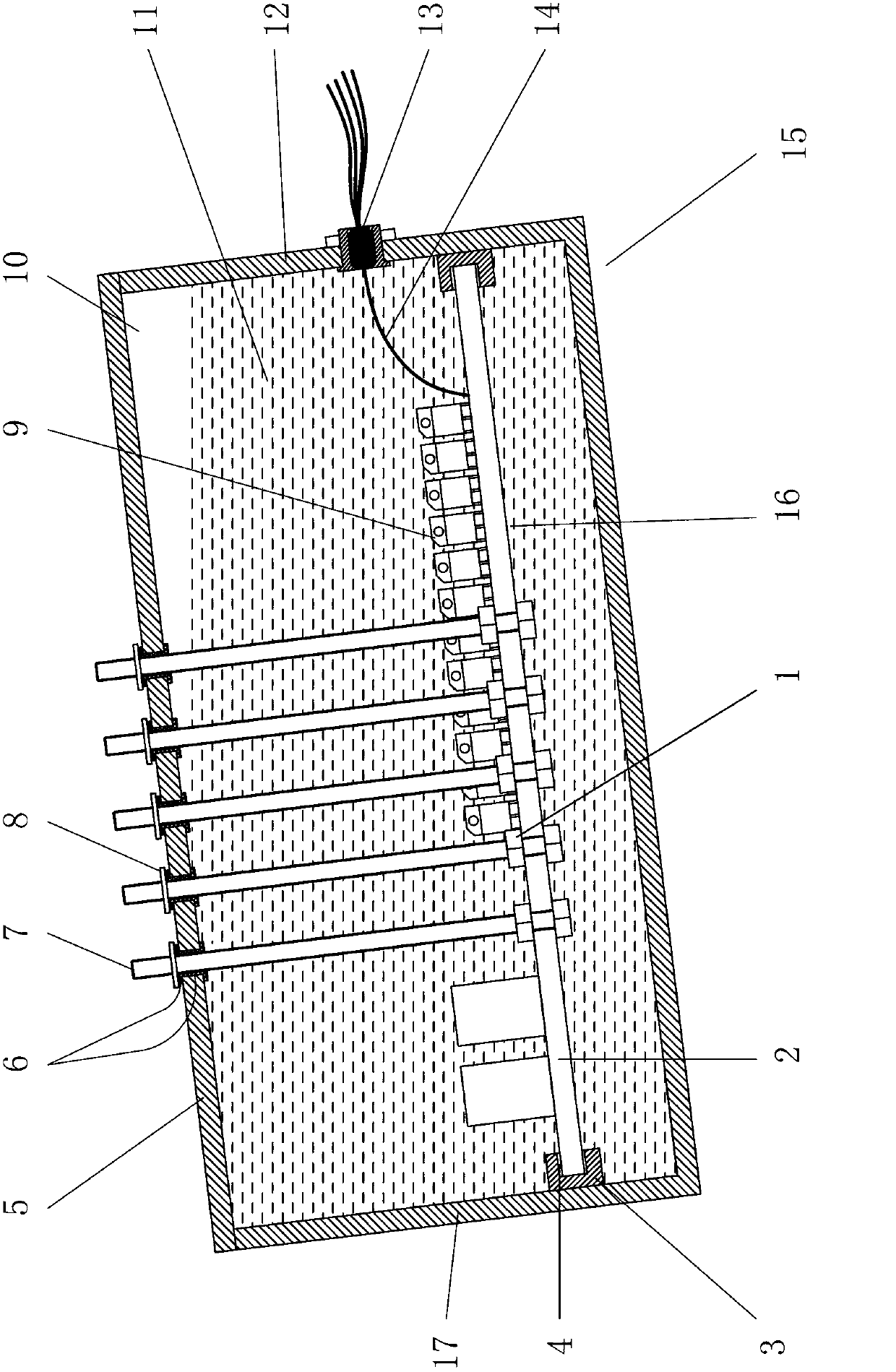

[0022] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 :

[0023] The liquid-cooled motor controller insulates and supports the circuit board 2 of the motor controller 16 containing power devices in a closed metal box 15, and the metal box 15 is filled with an insulating and heat-conducting liquid 11, and the inner wall of the metal box 15 and the liquid 11 A thermal expansion space 10 with liquid is arranged between them, and the wire 14 connected to the motor controller 16 is insulated and sealed to lead out of the metal box 15 .

[0024] Above-mentioned metal box 15 is the box that aluminum material or copper material are made at least three sides.

[0025] The above-mentioned liquid 11 is transformer oil or insulating oil or silicone oil or heat-conducting oil for insulation and heat conduction.

[0026] The heat energy generated by the operation of the power device 9 on the circuit bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com