Multi-tier automatic warehouse

An automatic and storage system technology, applied in the direction of transportation, packaging, storage devices, etc., can solve the problems of increasing facility cost, too much space, and the number of layers cannot be simply increased, and achieve small facility cost, less installation space, and high throughput performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings. In the drawings, the same or corresponding parts have the same reference numerals, and repeated descriptions will be omitted. For clarity, a suffix is appended to the reference designator, if required.

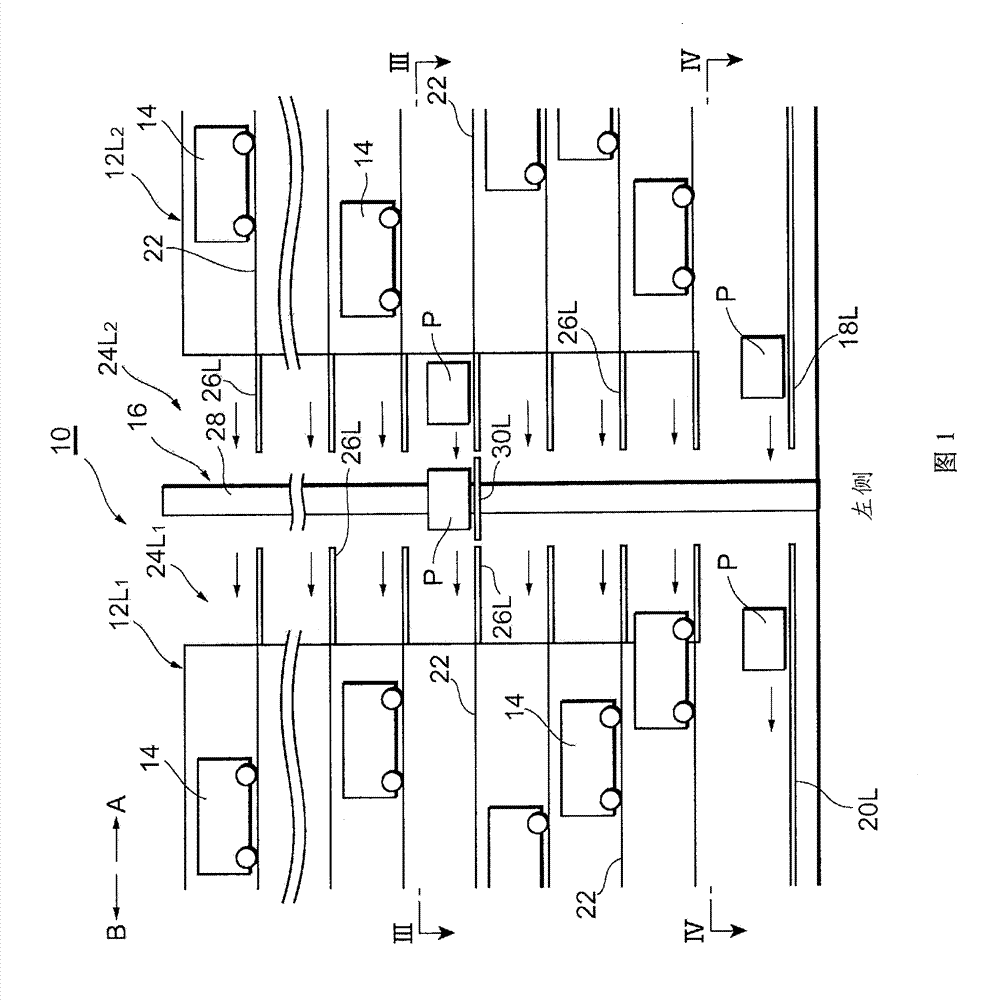

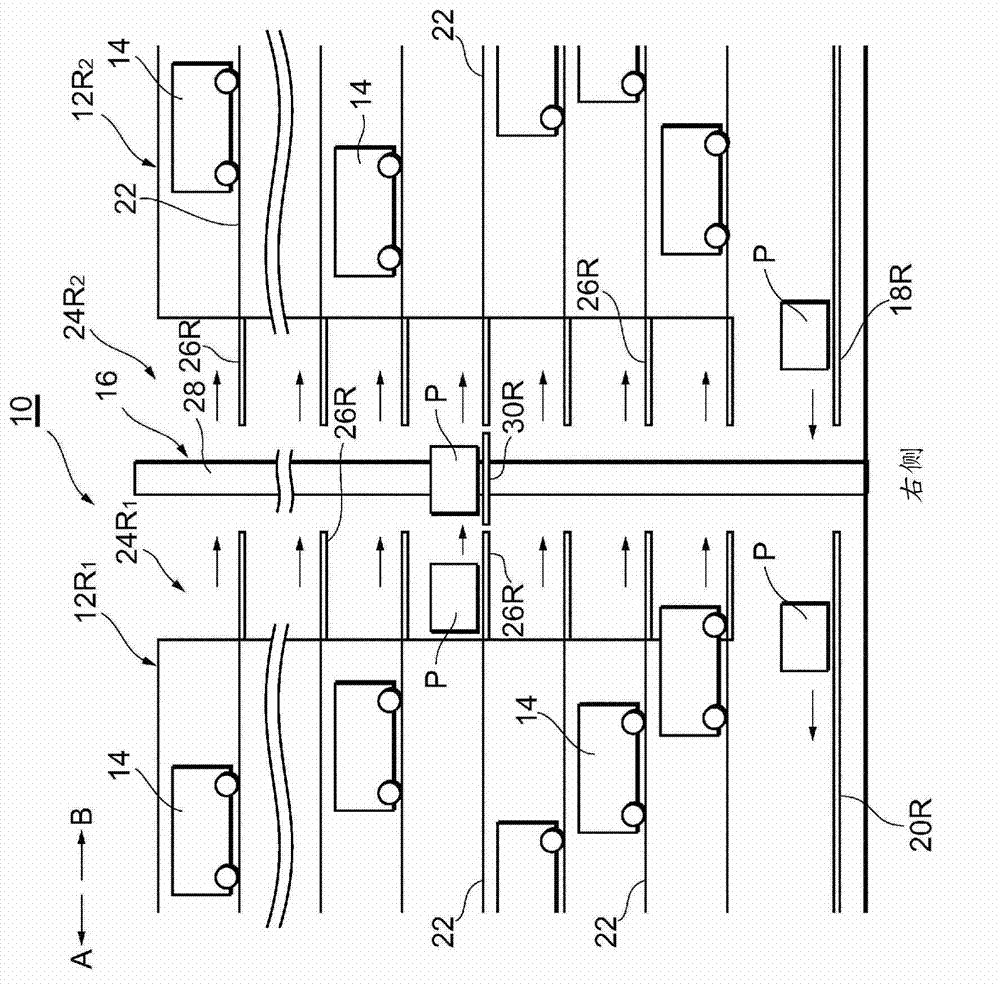

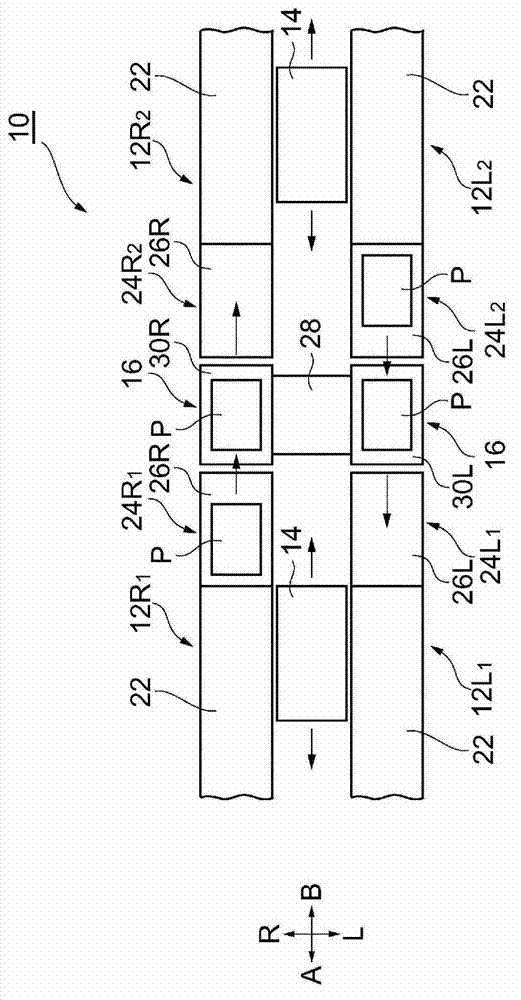

[0040] FIG. 1 is a schematic side view illustrating one side (left side) of an automatic storage system 10 according to one embodiment of the present invention. figure 2 is a schematic side view illustrating the other side (right side) of the automatic storage system 10 shown in FIG. 1 . image 3 is a schematic cross-sectional view taken along line III-III of FIG. 1 . Figure 4 is a schematic cross-sectional view taken along the line IV-IV of FIG. 1 , which includes an elevating table described later. This automatic storage system 10 includes and Figure 9 Shown are multi-level racks 12 , transfer shuttles 14 , elevators 16 , inbound conveyors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com