Plate-belt-type all-feeding harvester

A full-feed, harvester technology, used in harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of long conveying distance, high power output requirements, and many transmission parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

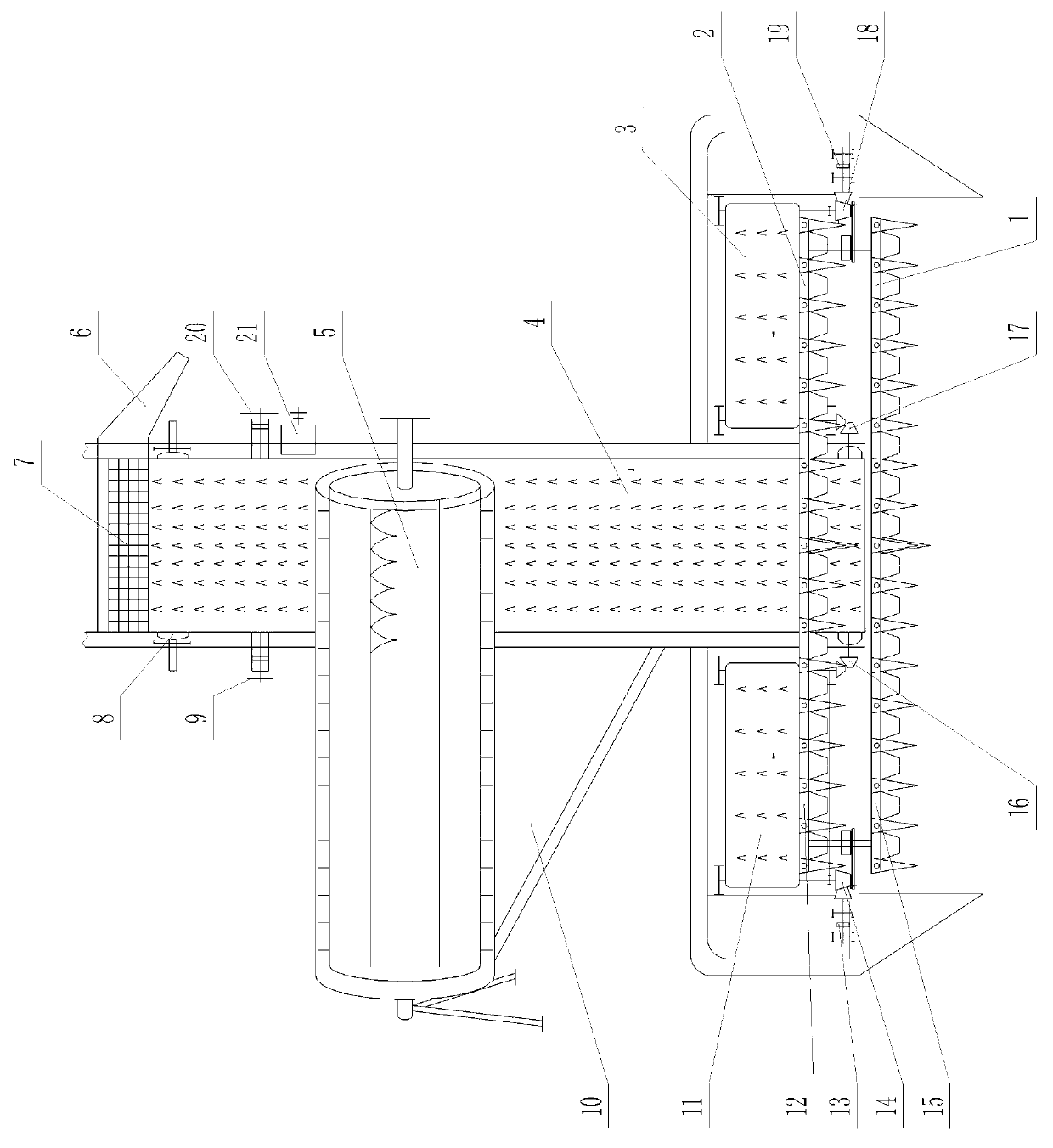

[0014] refer to figure 1 , a strip-type full-feed harvester, comprising upper and lower layers of cutters, threshing cylinder 5, fan and vibrating screen 7, the upper and lower layers of cutters are divided into left and right groups, two The group cutters operate separately, wherein the left group includes the upper left cutter 12 and the lower left cutter 15, and is connected with the power mechanism through the left cutter bar throwing wheel 14 to realize the operation of the upper and lower layers of cutters on the left; the right group includes The upper right cutting knife 2 and the lower right cutting knife 1 are connected with the power mechanism through the right cutter bar wheel 18 to realize the operation of the upper and lower layers of cutting knives on the right. Transmission wheel 13, right transmission wheel 19 of reel are connected with power mechanism, drive reel to rotate;

[0015] Also comprise rice conveyer belt, rice conveyer belt is divided into main ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com