Jacking ladle car and applications thereof in vacuum circulating degasification refining method

A ladle trolley and jacking technology, applied in the direction of lifting device, can solve the problems of complex process equipment, poor overall stability, large lifting stroke, etc., and achieve the effect of simplifying process equipment, convenient maintenance, and simplified operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

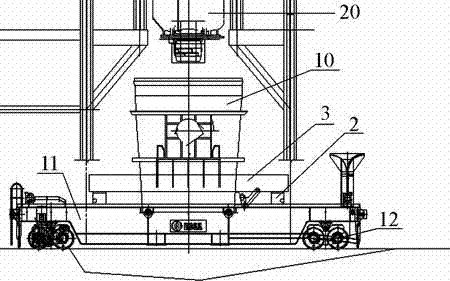

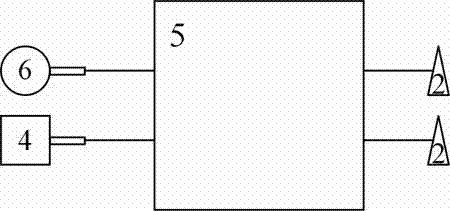

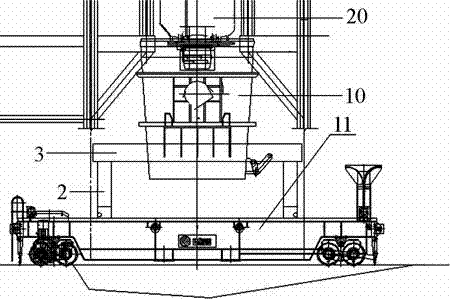

[0019] A jack-up type ladle trolley includes a car body 11, a wheel group 12, an electric jack 2, a support frame 3, an electric motor 4, a double-input double-output reducer 5 and an air motor 6, such as figure 1 and figure 2 As shown, the specific structure is: the four corners of the bottom of the vehicle body 11 are respectively provided with wheel sets 12, there are four electric jacks 2, the bases of the electric jacks 2 are respectively fixed on the four corners of the upper part of the vehicle body 11, the support frame 3 has four The lower part of the corner is provided with a pit, and the moving rods of each electric jack 2 are respectively fixed in the pits in the lower part of the four corners of the support frame 3; there are two motors 4 and two double-input double-output reducers 5, each with two The input double output reducer 5 has two input shafts and two output shafts. The rotating shaft of each motor 4 is connected to one input shaft of a double input doub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com