Preparation method of recycled aggregate concrete

A recycled aggregate and concrete technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of poor mechanical properties and durability, and achieve the goal of improving compressive strength and interfacial bond strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

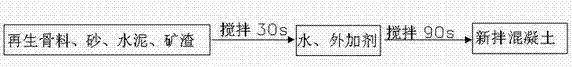

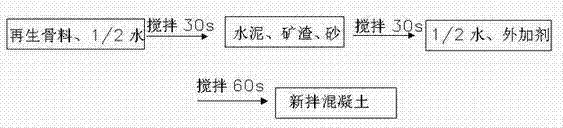

Method used

Image

Examples

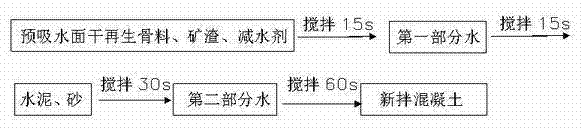

Embodiment 1

[0028] Add 1100 kg of regenerated aggregate, 70 kg of slag and 1.87 kg of polycarboxylate superplasticizer to the forced concrete and stir for 15 seconds, then add 15% (27 kg) of water and stir for 15 seconds, and then add 300 kg of Cement and 600kg of natural sand were mixed for 30s, and finally the remaining 85% (151kg) of water was added and stirred for 60s to form freshly mixed recycled aggregate concrete.

Embodiment 2

[0030] Add 900kg of regenerated aggregate, 80kg of slag and 2.31kg of polycarboxylate water-reducer to the forced concrete mixer and stir for 15s, then add 25% (46kg) water and stir for 15s, then add 300kg The cement and 600kg of natural sand were mixed for 30s, and finally the remaining 75% (136kg) of water was added and stirred for 60s to prepare freshly mixed recycled aggregate concrete.

Embodiment 3

[0032] Add 1200kg of regenerated coarse aggregate, 40kg of slag, 35kg of silica fume and 2.86kg of lignosulfonate sodium salt superplasticizer to the forced concrete mixer and stir for 15s, then add 18% (32kg) Then add 300kg of cement and 600 kg of natural sand and stir for 30s, and finally add the remaining 82% (148kg) of water and stir for 60s to prepare fresh recycled aggregate concrete.

[0033] The following table shows the 7d and 28d compressive strength results of the recycled aggregate concrete prepared in Examples 1, 2, and 3 of the present invention, and the recycled aggregate concrete prepared by the traditional primary mixing molding process and secondary mixing molding process. Wherein the raw materials and proportions adopted in the traditional primary and secondary stirring molding processes are consistent with those adopted in Example 3.

[0034] One-time mixing process Secondary mixing process Example 1 Example 2 Example 3 7d compress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com