Corrugated steel web-based steel-wood combined box girder

A technology of corrugated steel webs and steel-wood combination, which is applied in bridges, bridge materials, bridge construction, etc., can solve the problems of large influence of concrete setting effect, easy quality defect reinforcement maintenance, inconvenient transportation and installation, etc. Inconvenient transportation and installation, less affected by climate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

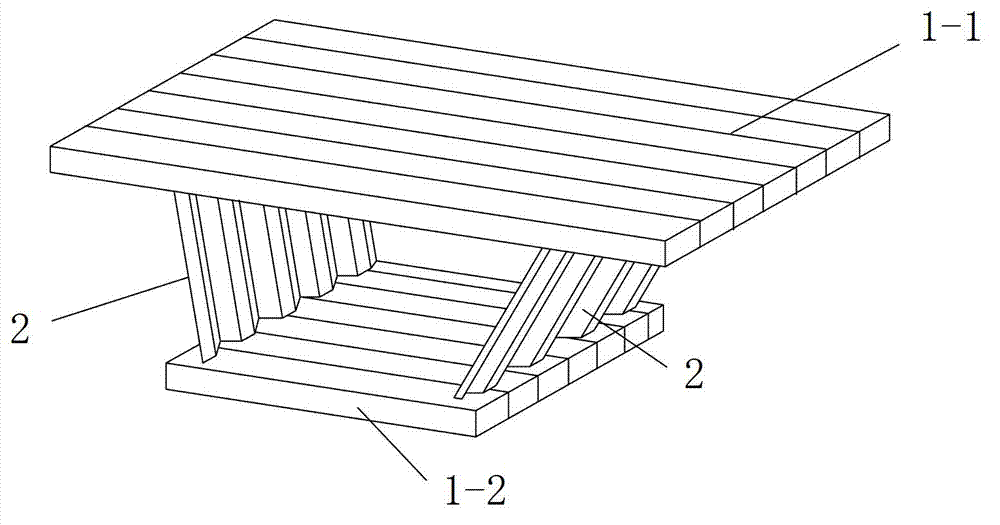

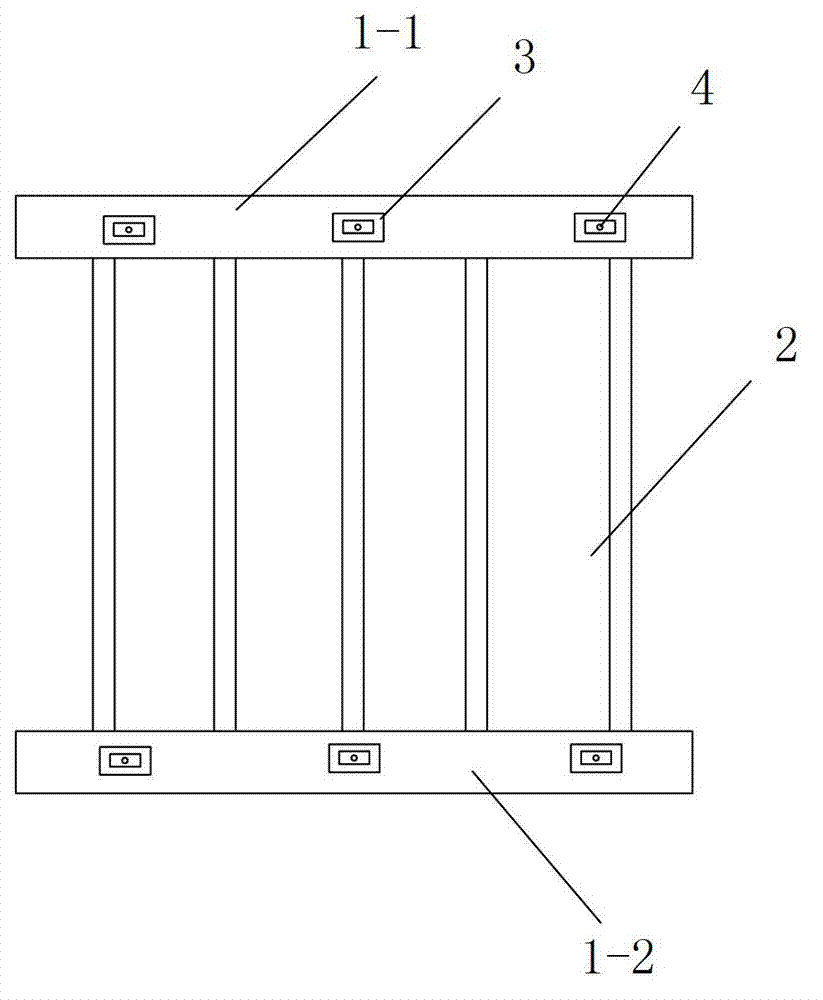

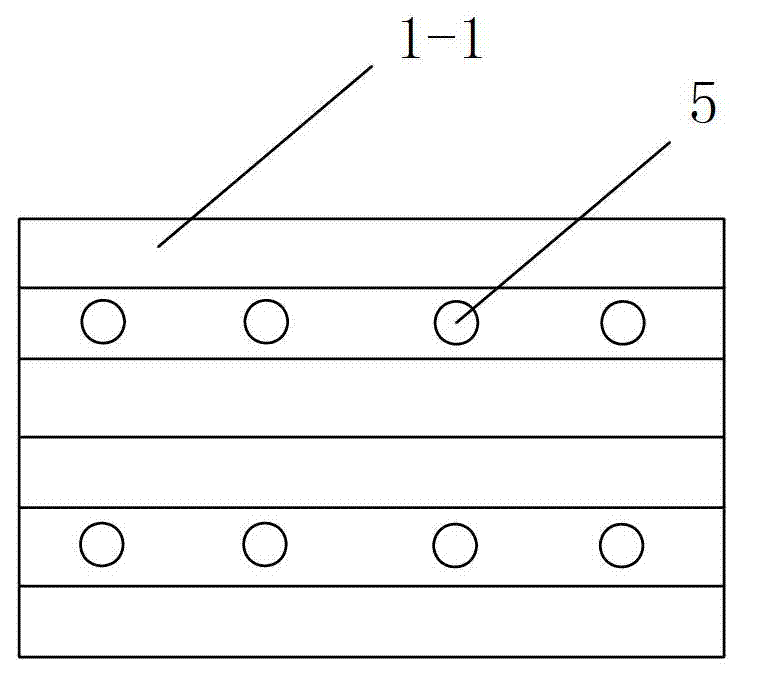

[0035] Such as figure 1 As shown, the present invention comprises a wooden top board 1-1, a wooden bottom board 1-2 positioned directly below the wooden top board 1-1 and two steel panels respectively arranged on the left and right sides between the wooden top board 1-1 and the wooden bottom board 1-2. The web 2, the wooden top plate 1-1 and the wooden bottom plate 1-2 are all arranged horizontally, and the two steel webs 2 are arranged symmetrically from left to right. Both the longitudinal length of the wooden top plate 1-1 and the wooden bottom plate 1-2 are consistent with the span of the constructed box girder, and the widths of both are consistent with the transverse width of the constructed box girder. combine figure 2 and Figure 5 , the wooden top board 1-1 and the wooden bottom board 1-2 are laminated wooden boards 6, and the laminated wooden boards 6 are composed of a plurality of strip-shaped wooden boards assembled side by side, and the plurality of strip-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com