High-formwork support system for roof

A high formwork and system technology, applied in formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problem of low bearing capacity of a single vertical pole of ordinary steel pipes, difficult to meet the needs of engineering formwork, housing construction, etc. Covering problems such as large spans, to achieve the effect of reducing potential safety hazards, reducing construction difficulty, and avoiding simultaneous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be described in detail below with reference to the accompanying drawings.

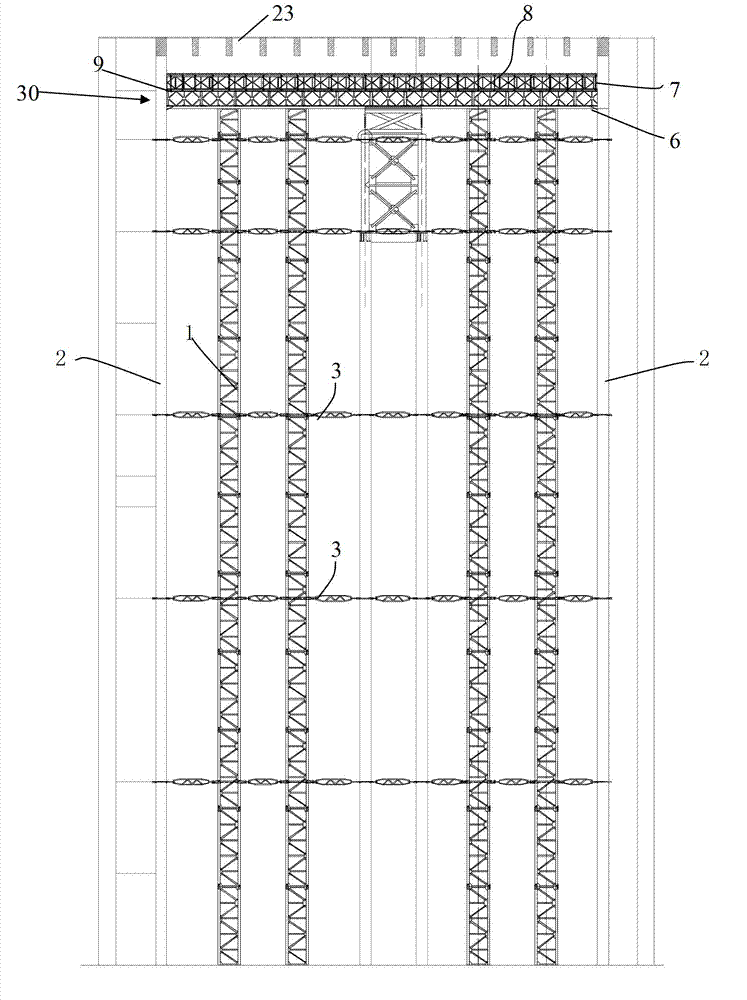

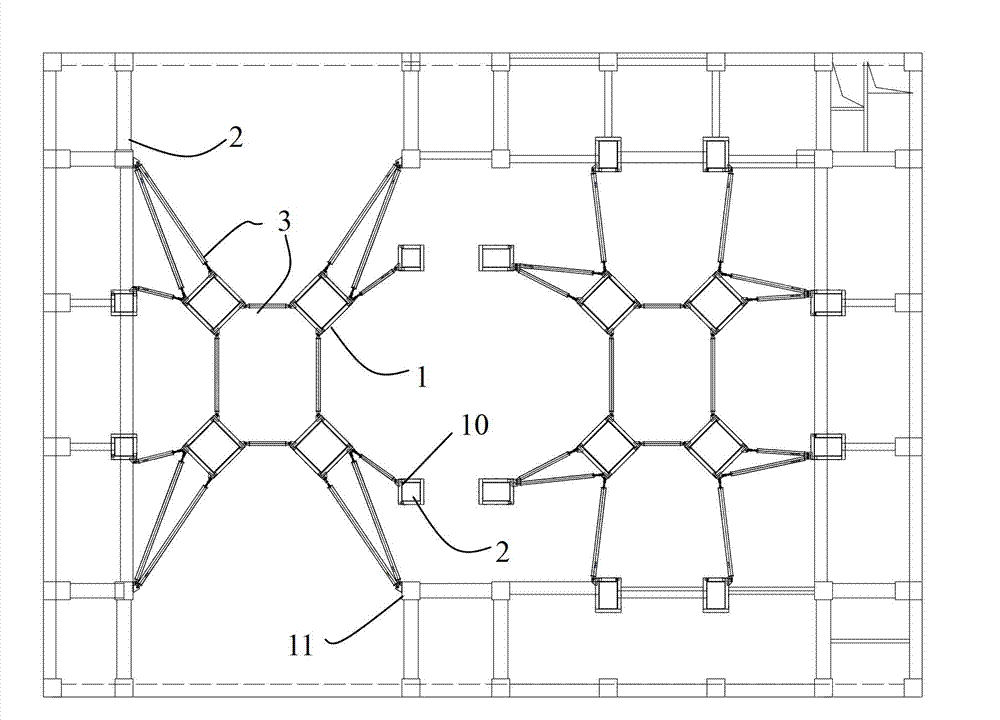

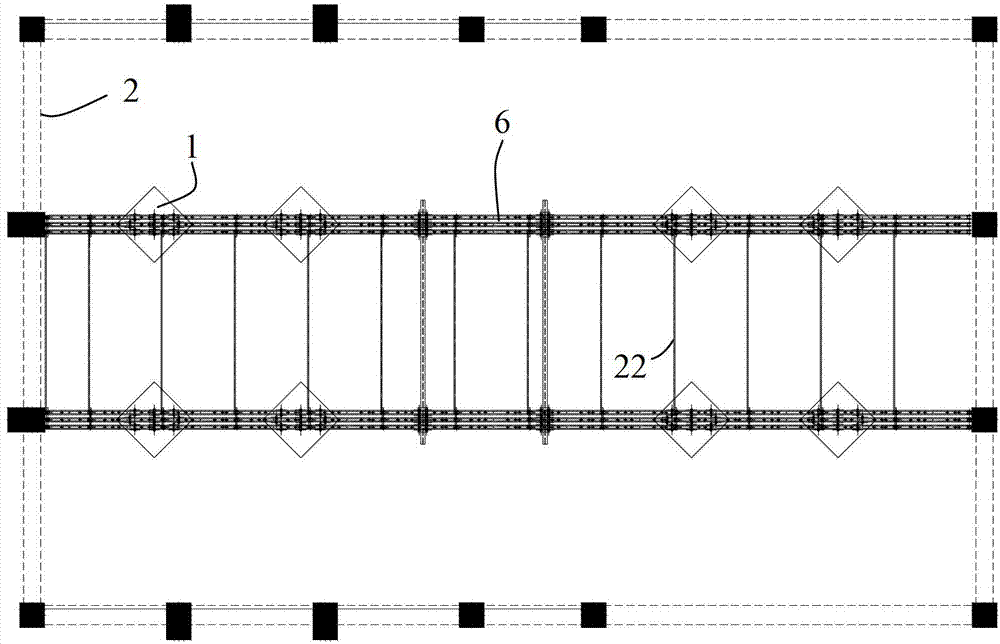

[0022] Please see figure 1 , figure 2 and Figure 5 , The high roof formwork system of the present invention includes a plurality of lattice columns 1 and a horizontal grid platform 30 . A plurality of lattice columns 1 are used as vertical supports to support the horizontal grid platform 30, and a plurality of horizontal tie rods 3 are connected at a certain height between each lattice column 1 and the main vertical structure 2 as required , the horizontal tie rod 3 is connected with the main body vertical structure 2 through the hoop 10 or the embedded part 11 . The lattice column 1 is connected with the basic structure 24 through the steel base 12 . On the horizontal grid platform 30 is the well-shaped beam roof 23 to be poured.

[0023] The horizontal grid platform 30 includes a Bailey beam grid 9 and a steel bridge deck 8, wherein t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com