A fuel tank oil-gas separation structure assembly

A technology of separation structure and oil and gas separation chamber, which is applied to gasoline barrels, liquid fuel feeders, adding non-fuel substances to fuel, etc., can solve problems such as inability to separate oil and gas, insufficient space volume, and increase manufacturing costs, and achieve a simple structure. Reasonable and compact, avoid solder joint loosening, reliable effect of oil and gas separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

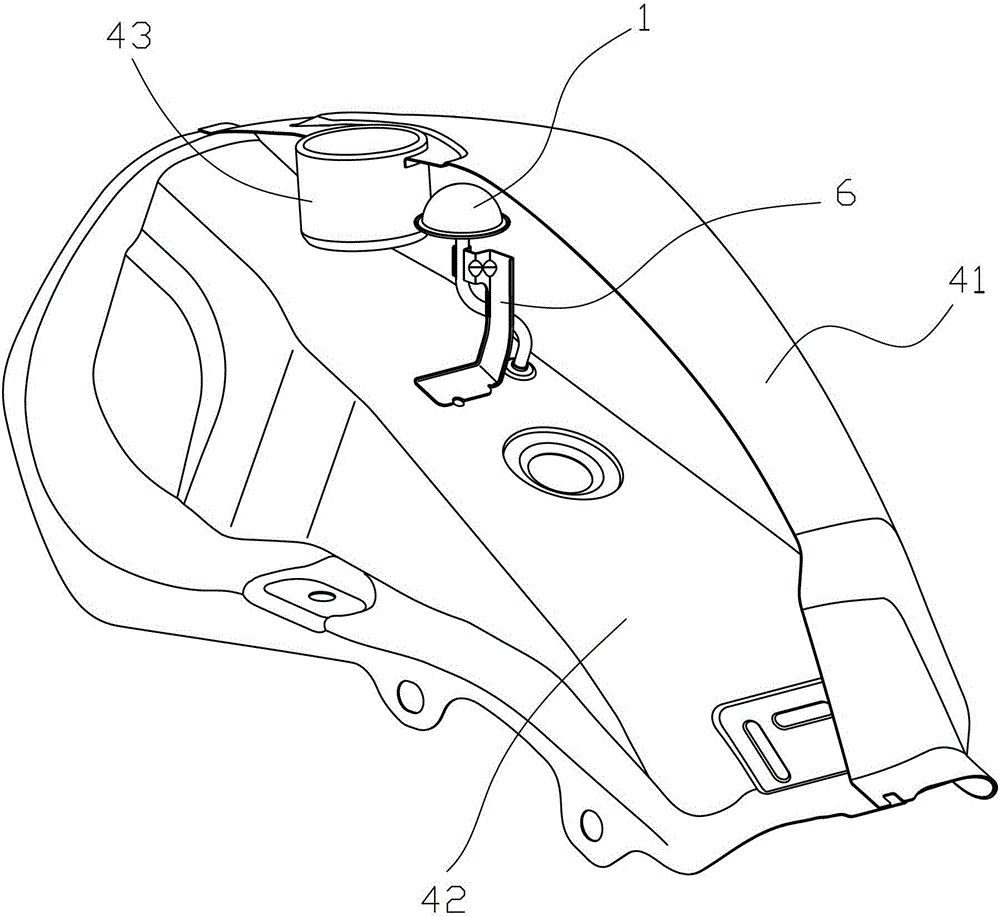

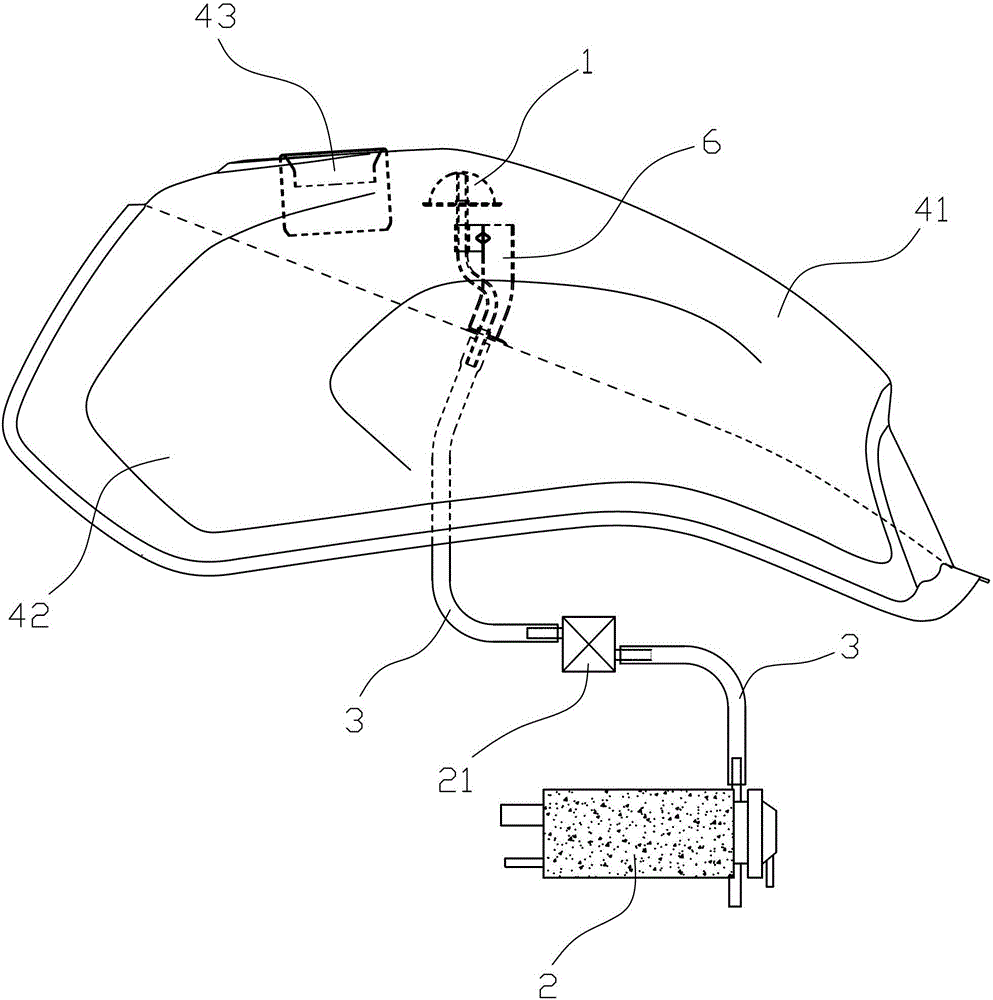

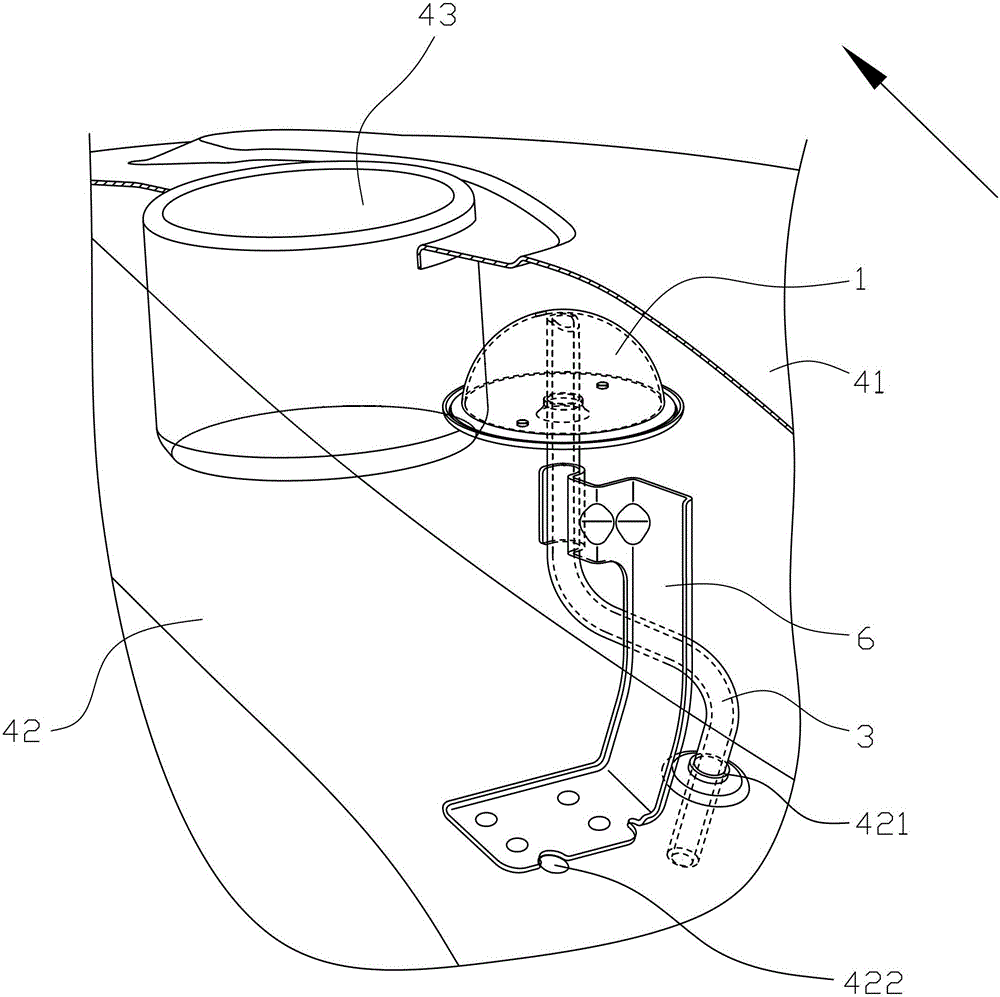

[0031] refer to Figure 1~Figure 9 , a fuel tank oil-gas separation structure assembly of the present invention, which includes a fuel tank and an oil-gas separation device arranged in the fuel tank, the oil-gas separation device includes an oil-gas separation chamber 1 and a vent pipe connecting the oil-gas separation chamber 1 and the carbon tank 2 3. The oil-gas separation chamber 1 is composed of an upper part 11 and a lower part 12. The fuel tank is divided into an upper casing 41 and a lower casing 42. One end of the breather pipe 3 passes through the perforation 121 provided on the lower part 12 of the oil-gas separation chamber. After that, it communicates with the oil-gas separation chamber 1, and the other end of the vent pipe 3 passes through the through hole 421 provided on the lower casing 42 to communicate with the carbon canister 2, preferably after the vent pipe 3 passes through the lower casing 42, it can be connected with a dump stop valve 21 to prevent the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com