Monitoring system and monitoring method for boiler furnace flue gas velocity based on acoustics

A boiler furnace, flue gas flow velocity technology, applied in fluid velocity measurement, velocity/acceleration/impact measurement, measurement device, etc. Overcome flue gas flow instability and wide measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention provides an acoustic-based boiler furnace flue gas velocity monitoring system and monitoring method. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

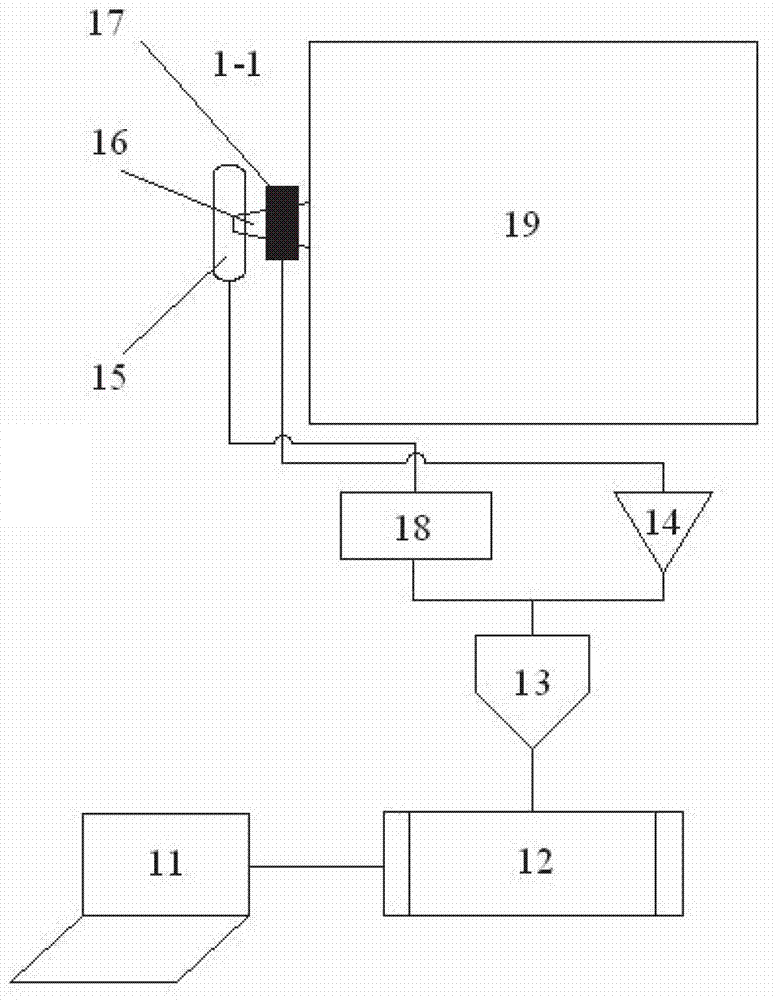

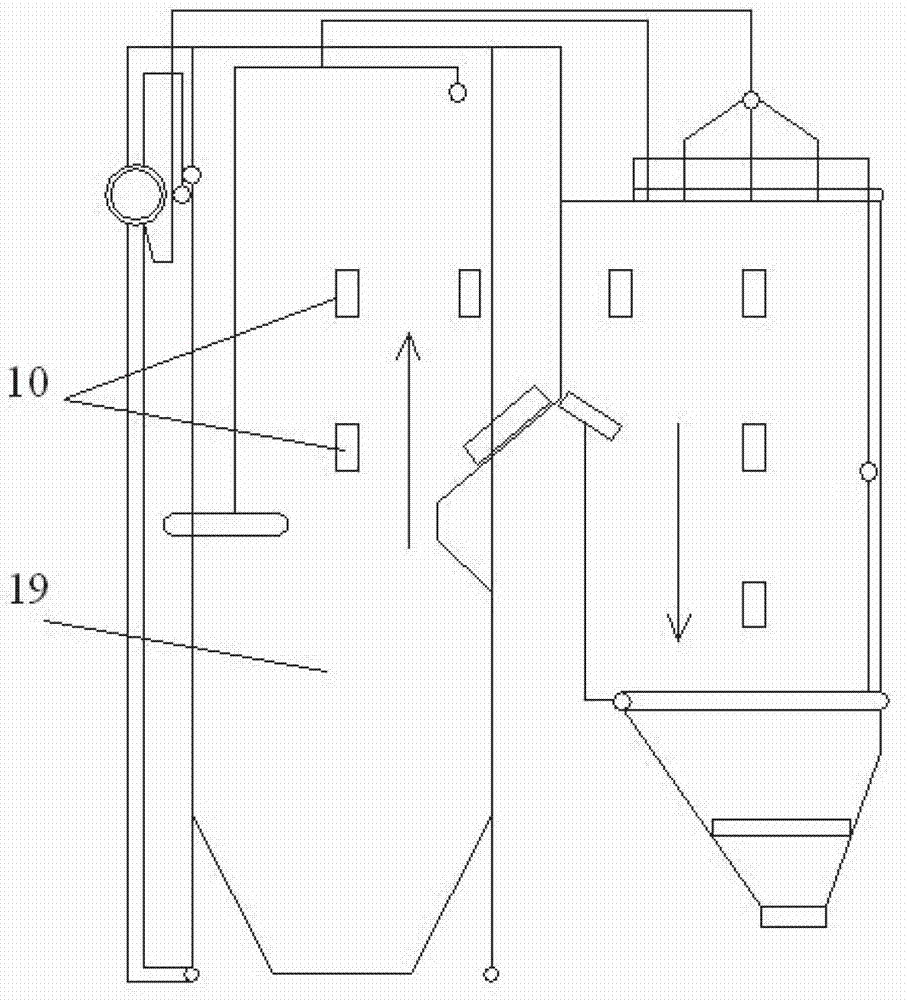

[0019] figure 1 Schematic diagram of the furnace flue gas velocity monitoring system. On the inner wall of the furnace 19 side where the flue gas flows, a measuring point is evenly arranged every 4-6 meters, and a set of monitoring devices are installed at each measuring point; The sound wave transceiver 10 that device 15 and electret type microphone 17 are formed is arranged at the measuring point; Sound wave generating device 15 is connected to power amplifier 14, and power amplifier 14 is connected with junction box 13 output ends; Electret type microphone 17 is connected to signal conditioning Device 18, signal conditioner 18 is connected with the input terminal of junction box 13; Junction box 13 is connected with dua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com