NOx emission control system for low-heating-value lignite

An emission control system and low calorific value technology, which is applied to controllers with specific characteristics, electric controllers, gas treatment, etc., to achieve the effects of timeliness, overcoming inaccurate NOx measurement, and overcoming the large delay in denitrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

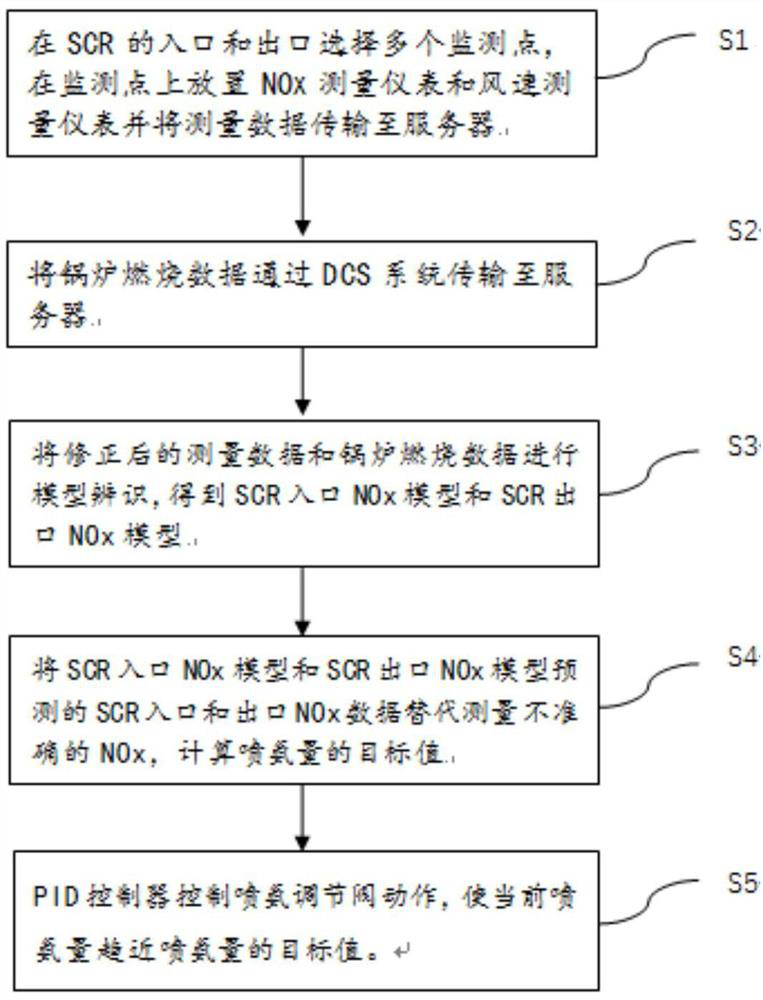

[0041] Please refer to figure 1 , a NOx emission control system for low calorific value lignite, comprising the following steps:

[0042] Step S1: select a plurality of monitoring points at the entrance and exit of the SCR, in the present embodiment, select 3-5 monitoring points, thereby ensure the accuracy of detection data, and place NOx measuring instrument and wind speed measuring instrument on the monitoring point And the measurement data is transmitted to the server, the NOx measuring instrument is a handheld Testo350 flue gas analyzer, and the wind speed measuring instrument is a handheld Testo425 thermal anemometer;

[0043] Step S2: the boiler combustion data is transmitted to the server through the DCS sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com