Color filter and forming method thereof

A color filter and color-resist layer technology, which is applied in the direction of optical filters, optics, and optomechanical equipment, can solve problems affecting the orderly arrangement of liquid crystals and light leakage at the edge of pixels, so as to achieve easy alignment and prevent light leakage at the edge of pixels , forming the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

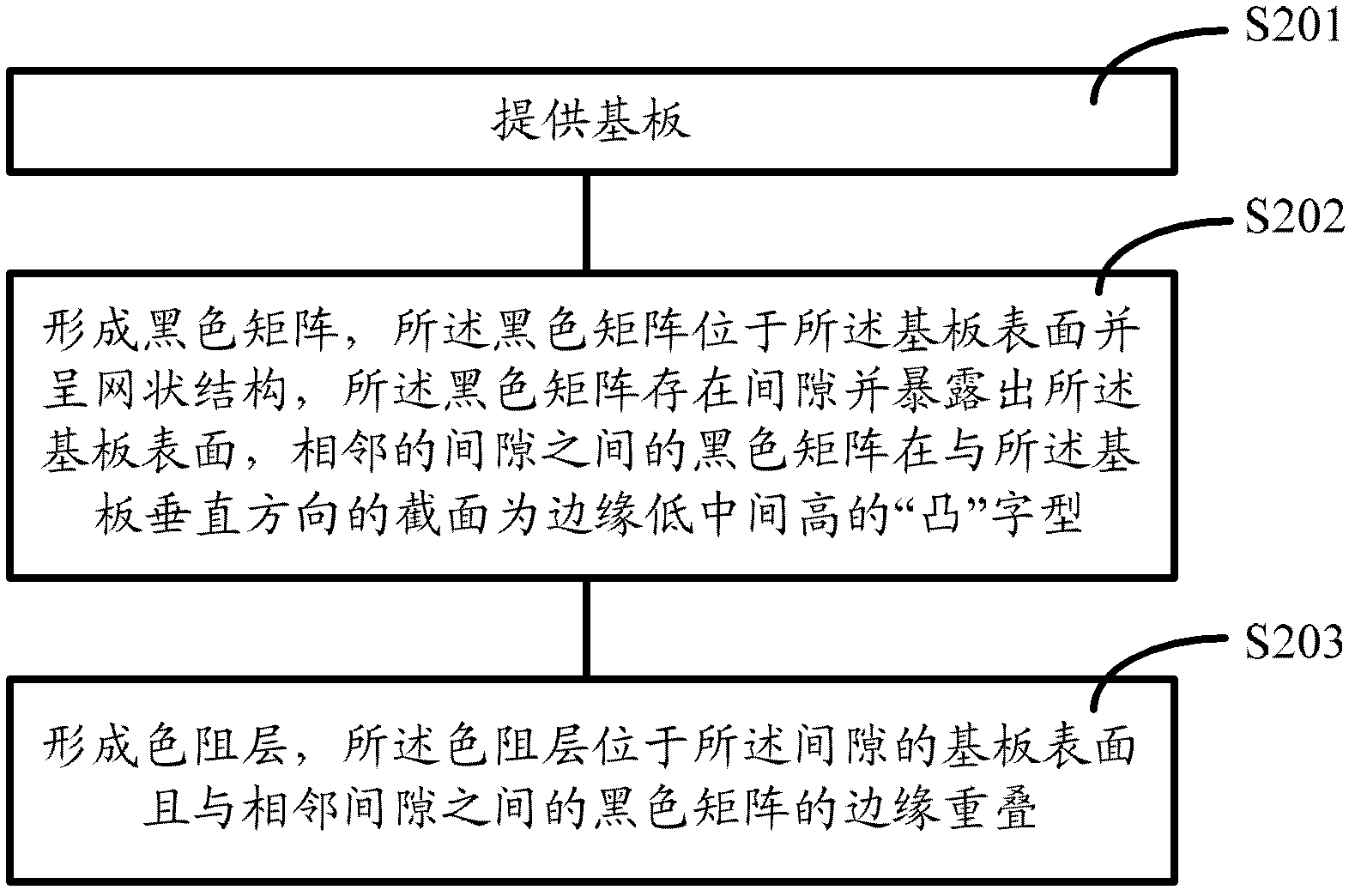

[0041] Please refer to figure 2 , the inventor of the embodiment of the present invention provides a method for forming a color filter, including:

[0042] Step S201, providing a substrate;

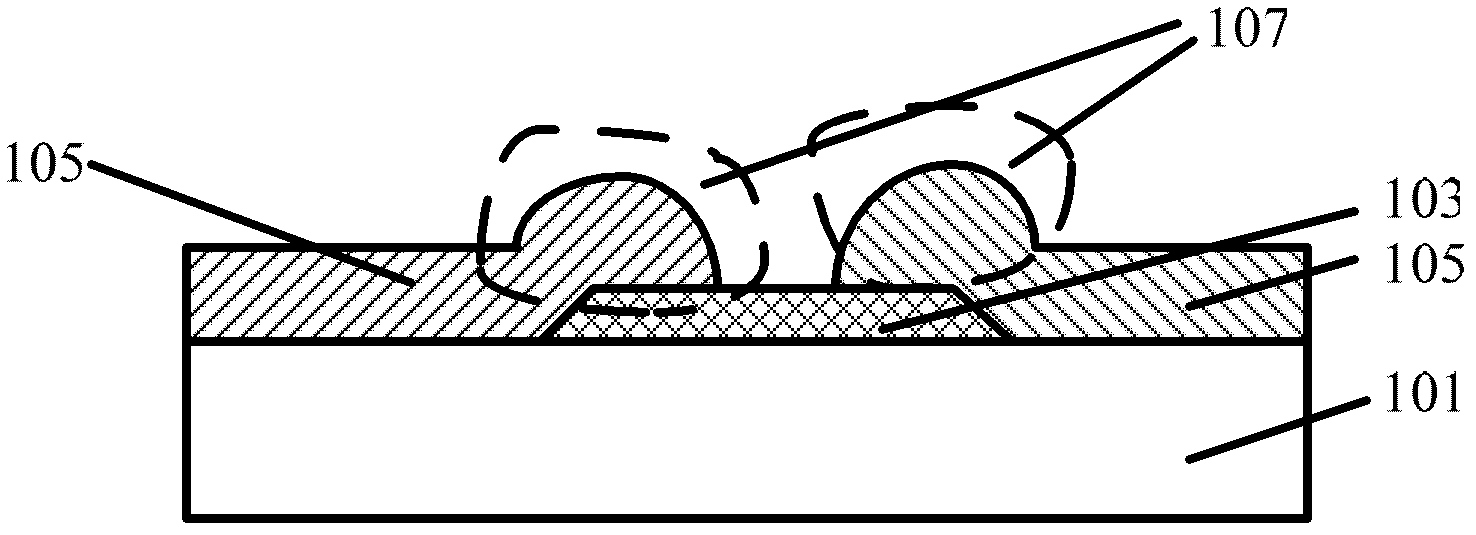

[0043] Step S202, forming a black matrix, the black matrix is located on the surface of the substrate and has a network structure, the black matrix has gaps and exposes the surface of the substrate, and the black matrix between adjacent gaps is perpendicular to the substrate The cross-section of the direction is a "convex" shape with low edges and high middle;

[0044] Step S203 , forming a color-resist layer, the color-resist layer is located on the substrate surface of the gap and overlaps with the edge of the black matrix between adjacent gaps.

[0045] In this embodiment, specific reference can be made to Figure 3 ~ Figure 6 Schematic diagram of the cross-sectional structure of the method for forming the color filter.

[0046] Execute step S201, please refer to image 3 , pro...

no. 2 example

[0070] Please refer to Figure 8 , the inventors of the embodiments of the present invention also provide a method for forming a color filter, including:

[0071] Step S401, providing a substrate, a black matrix with a network structure is formed on the surface of the substrate, the black matrix has gaps and exposes the surface of the substrate;

[0072] Step S402, forming a color-resist layer, the color-resist layer is located on the surface of the substrate and at the edge of the black matrix between adjacent gaps, and the thickness of the color-resist layer at the edge of the black matrix between adjacent gaps is less than The thickness of the color resist layer on the surface of the substrate.

[0073] In this embodiment, specific reference can be made to Figure 9 ~ Figure 10 Schematic diagram of the cross-sectional structure of the method for forming the color filter.

[0074] Execute step S401, please refer to Figure 5 with Figure 9 A substrate 501 is provided, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com