Control method and control system for inhibiting low-frequency oscillation of magnetic bearing system

A magnetic bearing and low-frequency oscillation technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems of sensor lead-out line and magnetic bearing power line length, system oscillation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050]The present invention also provides a magnetic bearing system, which includes a frame, a rotor, a prime mover and its driver, a magnetic bearing, a rotor displacement sensor, a power amplifier, a monitoring computer, and a control computer. The rotor displacement sensor is arranged on the frame, The output end of the rotor displacement sensor is electrically connected to the control computer, and is also connected to the monitoring computer. The command output of the control computer is electrically connected to the power amplifier. The magnetic bearing is arranged on the frame, and the input end of the magnetic bearing It is electrically connected to the power amplifier, and the rotor is fixedly connected to the prime mover or mechanically connected through a coupling. In addition to being connected to the prime mover, the rotor has no mechanical contact with other parts in the system in the working state, and a certain gap is maintained. The preset in the control compute...

Embodiment 2

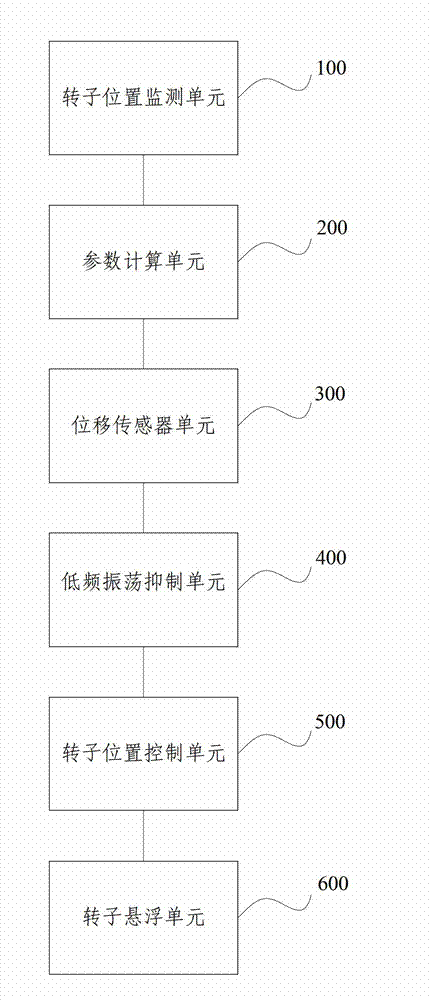

[0070] The present invention provides a magnetic bearing control system, which includes a rotor, and further includes:

[0071] A rotor position monitoring unit (100), used to record the rotor position oscillation waveform, and calculate the oscillation frequency f according to the oscillation waveform O ;

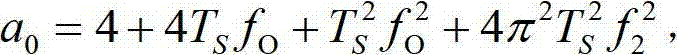

[0072] A parameter calculation unit (200), for setting the sampling period T S , phase compensation band half-band width f B , according to the system oscillation frequency f O , sampling period T S and the half-bandwidth of the phase compensation band f B Calculating the parameters of the low-frequency oscillation suppression unit;

[0073] A displacement sensor unit (300), used to collect the displacement value of the rotor;

[0074] A low-frequency oscillation suppression unit (400), configured to calculate a signal after low-frequency suppression according to the displacement value and the parameters of the low-frequency oscillation suppression unit;

[0075] A ...

Embodiment 3

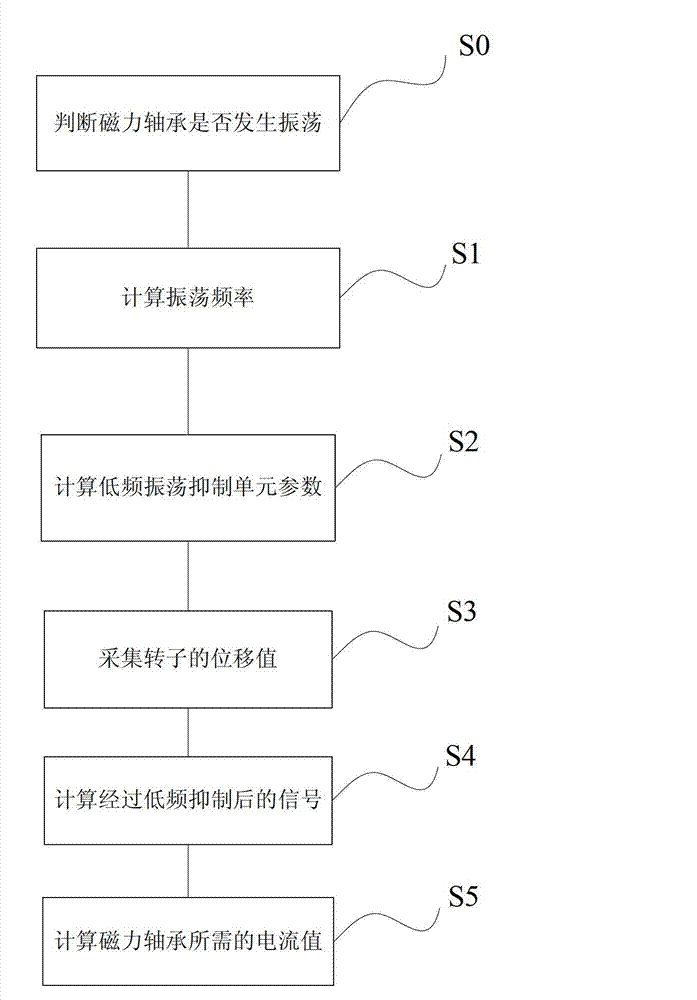

[0080] The present invention also provides a magnetic bearing control method, which includes the following steps:

[0081] S1. Record the rotor position oscillation waveform, and calculate the oscillation frequency f according to the oscillation waveform O ;

[0082] S2. Set the sampling period T S , phase compensation band half-band width f B , according to the system oscillation frequency f O , sampling period T S and the half-bandwidth of the phase compensation band f B Calculating the parameters of the low-frequency oscillation suppression unit;

[0083] S3. collecting the displacement value of the rotor;

[0084] S4. Calculate the signal after low-frequency suppression according to the displacement value and the low-frequency oscillation suppression unit parameters;

[0085] S5. Calculate the current value required by the magnetic bearing according to the signal after the low-frequency suppression;

[0086] S6. Suspending the rotor according to the current value. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com