Wireless communication robot winding control system

A control system and wireless communication technology, applied in the field of prestressed steel wire winding robot control system, can solve problems such as large fluctuations, affecting winding quality, and unstable analog signals, so as to reduce fluctuations, improve winding construction quality, and signal transmission stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the examples, and the purpose is only to better understand the content of the present invention. Therefore, the examples given do not limit the protection scope of the present invention.

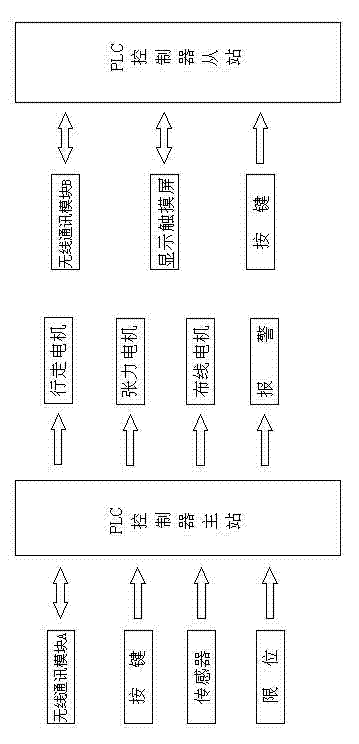

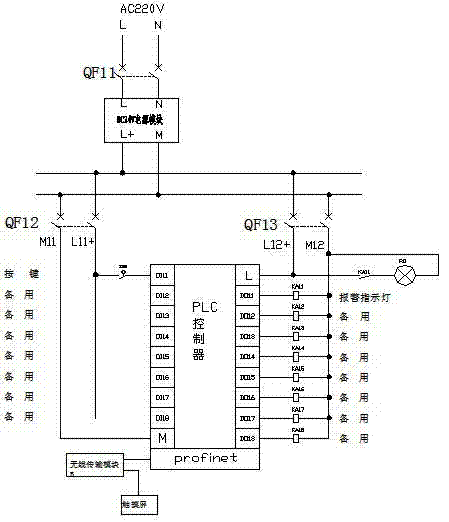

[0030] see figure 1 , The wireless communication robot winding control system consists of a PLC master controller and a PLC slave controller.

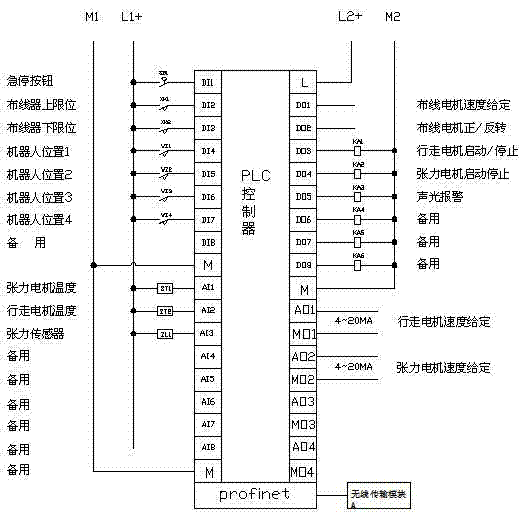

[0031] The PLC master station controller includes three parts: input, output and wireless communication module, among which:

[0032] ①The input part consists of three parts: emergency stop button, switch signal detection and analog signal detection. The emergency stop button is installed on the robot, and it is manually operated by humans in case of emergency. The switch signal is the limit signal of the router, and the wiring direction of the robot when winding is automatically controlled according to the limit signal.

[0033] ②The output part includes tension mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com