Mixing stirrer with paddle with airflow driven by air pressure

A technology of air pressure drive and agitator, which is applied in mixers, chemical instruments and methods, dissolution, etc., can solve the problems of complex equipment structure, pollution, heat dissipation, etc., and achieve the effects of rational use of resources, reduction of production costs, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

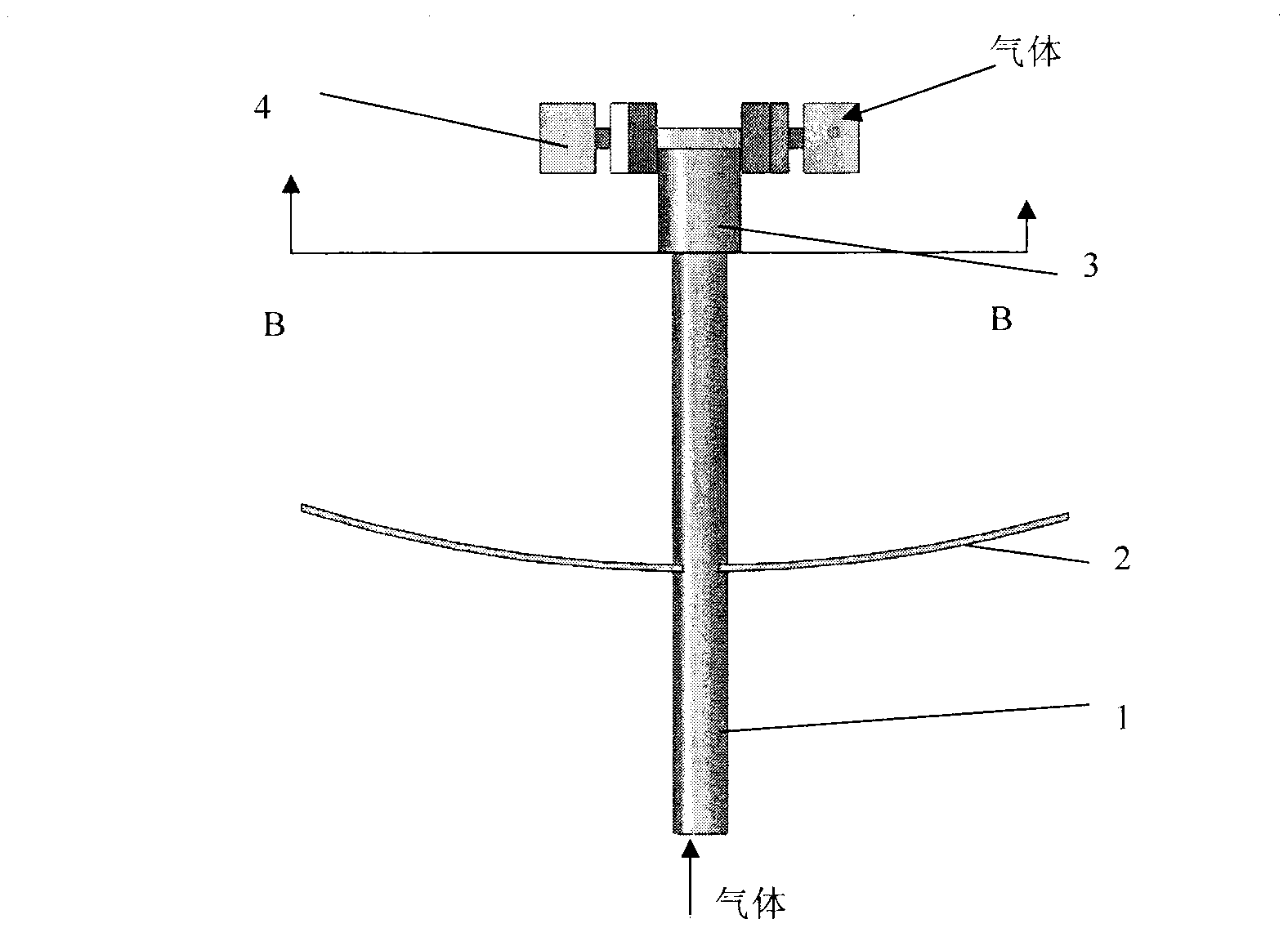

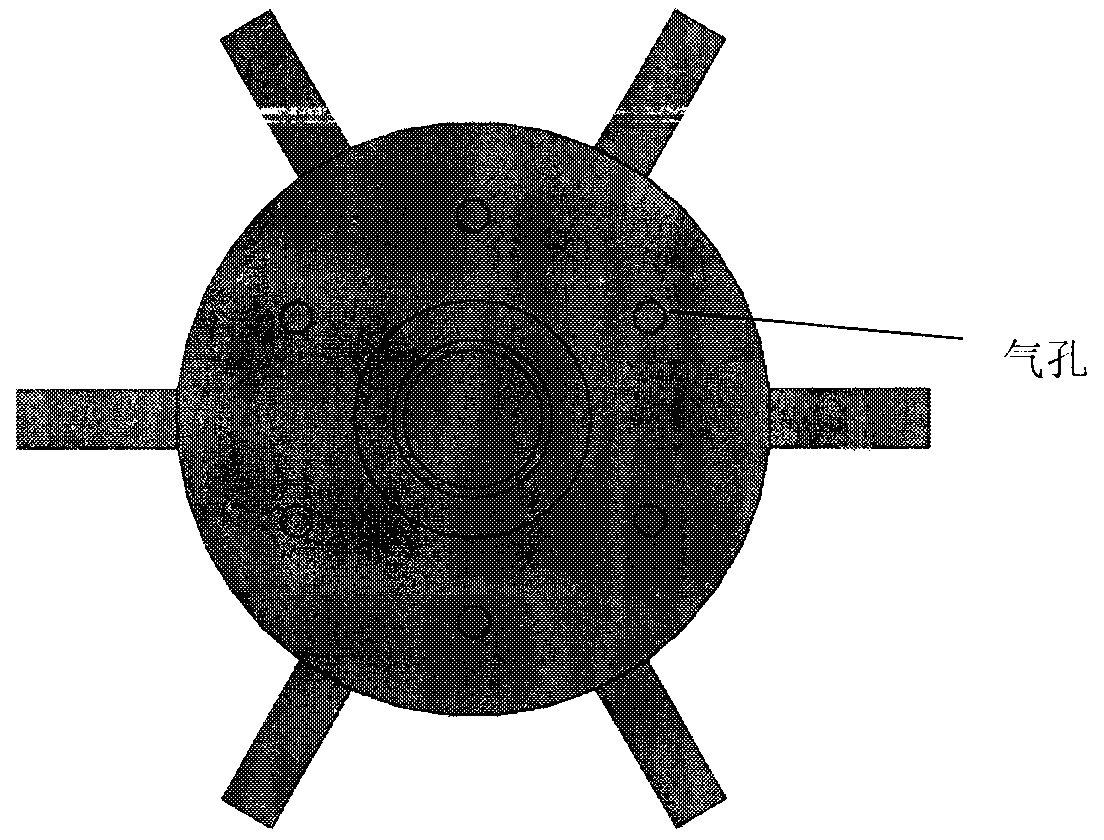

[0011] Such as figure 1 According to different working conditions, the gas with appropriate temperature and pressure is selected from the outside through the vent pipe (1), passes through the one-way vent valve (3), and enters the set distributed air holes and drive on the hollow stirring blade (4). Vent discharge, distribution The gas discharged from the vent directly acts on the liquid to distribute and stir, and the vent gas is driven to generate a rotational driving force. When the gas pushes the stirring blade (4) to rotate, the ejected gas is evenly distributed in the liquid , the rotating stirring paddles (4) push the liquid to stir to play the role of mechanical stirring, making full use of the positive and negative kinetic energy of the air pressure, which can effectively save energy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com