Full automatic wireless remote control system of welding manipulator

A wireless remote control and wireless remote control technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as extrusion, cable wear, and weak signals, reducing ineffective links, improving welding efficiency, and flexible use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

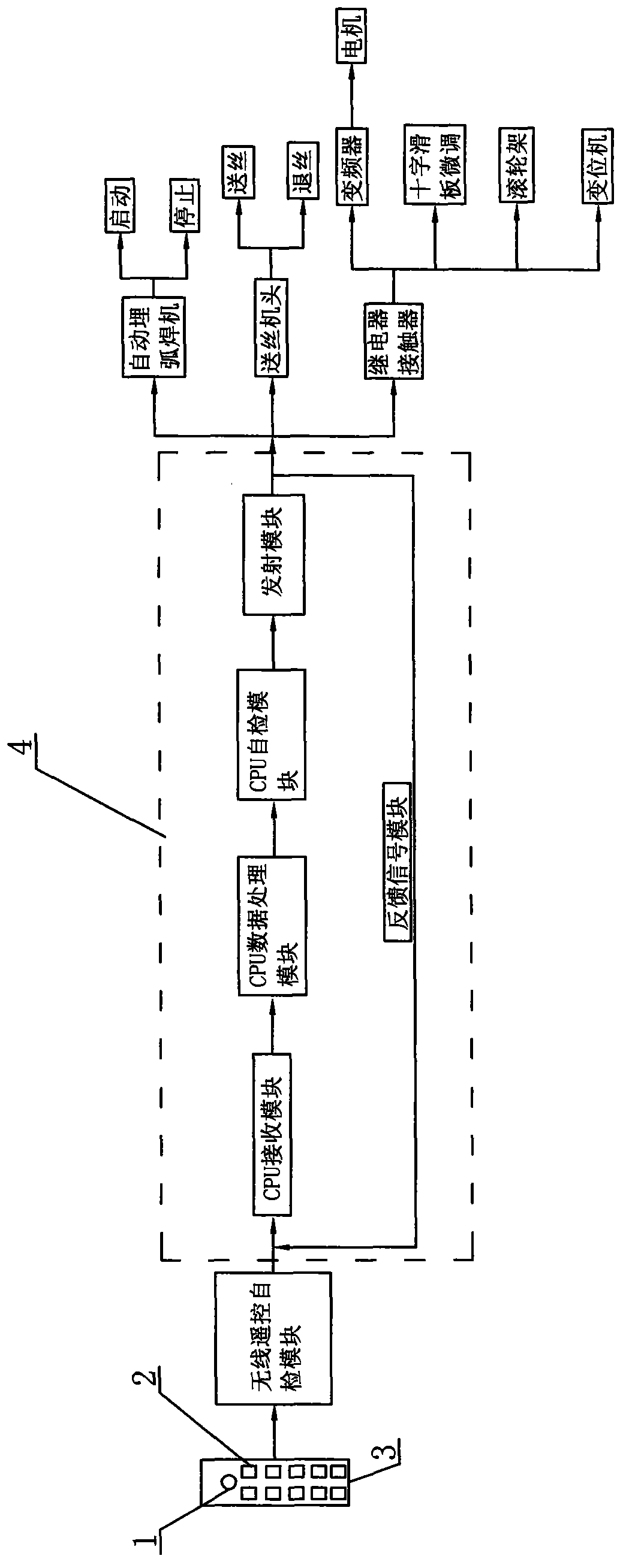

[0016] Such as figure 1 A fully automatic wireless remote control system for a welding manipulator, comprising a wireless remote controller 3 and a receiver 4, the wireless remote controller 3 is provided with a button 2, and the button 2 adopts a building block type long-stroke button; the wireless remote controller 3 is provided with an emergency stop switch 1; the receiver 4 includes a CPU receiving module, a CPU data processing module, a CPU self-checking module, a transmitting module, and a feedback signal module are electrically connected; the automatic submerged arc welding machine, the wire feeder head, and the relay contactor are all electrically connected to the receiver 4 connected, and executed after receiving instructions from the receiver 4; the automatic submerged arc welding machine is connected with the pneumatic and stop electricity; , Roller frame, displacement electromechanical connection; frequency converter is electrically connected to the motor. When in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com