Underwater granulation apparatus used for polymer extrusion foaming

A technology of underwater granulation and extrusion foaming, applied in the field of mechanical equipment and manufacturing, to achieve the effect of large specific heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

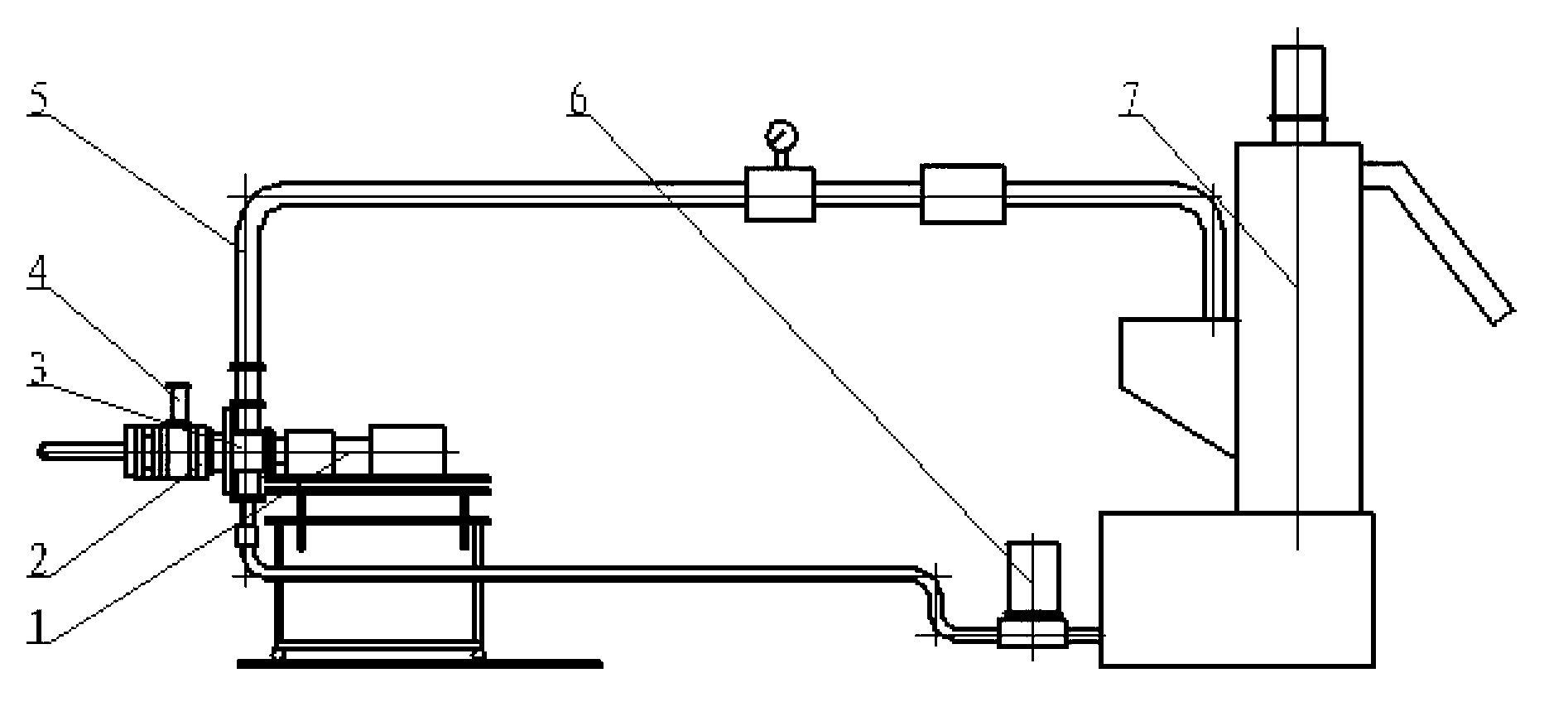

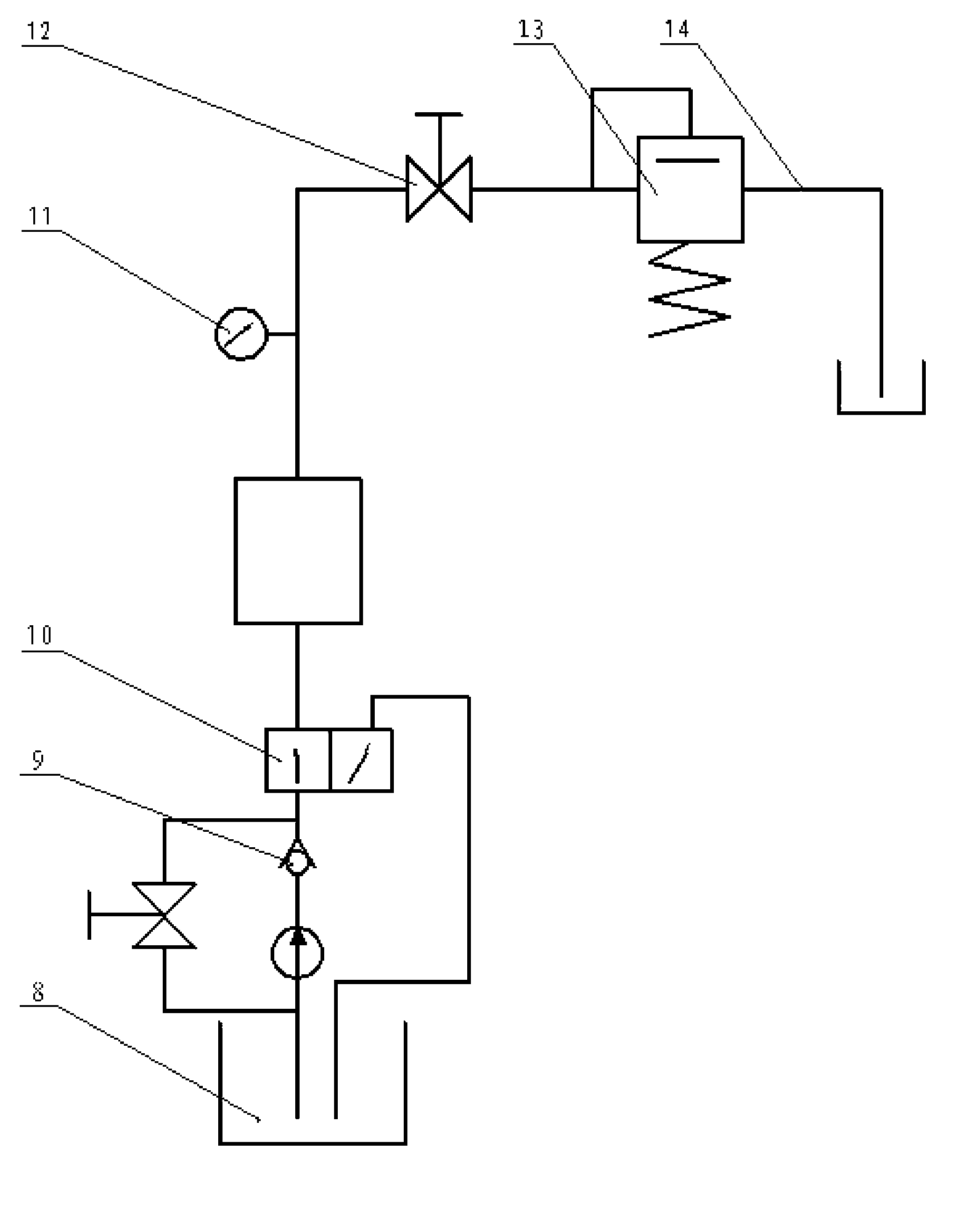

[0020] See attached figure 1 , an underwater granulation device for polymer extrusion and foaming, including a pelletizer 1, the pelletizer 1 is closely attached to the underwater pelletizer head 2 through an axial locking device, and the underwater pelletizer Both sides of the head 2 are equipped with a driving valve 4 and a cutting chamber 3. The cutting chamber 3 is connected with a water circulation system 5. The water circulation system 5 is connected with a dehydrator 7 and a high-pressure water pump 6. The water pipes 14 of the water circulation system 5 are respectively connected in series. Water tank 8, high-pressure water pump 6, one-way valve 9, reversing valve 10, pressure gauge 11, stop valve 12, back pressure valve 13; check valve, reversing valve, pressure gauge, stop valve, back pressure valve include direct Dynamic manual adjustment valves, including pilot valves or pneumatic, hydraulic or electric control valves with remote control; pressure gauges include m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| specific heat capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com