Self-correct guide front wheel mechanism of rail guide vehicle for installing commercial vehicle rear axle assembly line

A technology for assembly lines and commercial vehicles, which is applied in the direction of wheels, wheels characterized by rail running parts, and motor vehicles. The effect of improving reliability and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

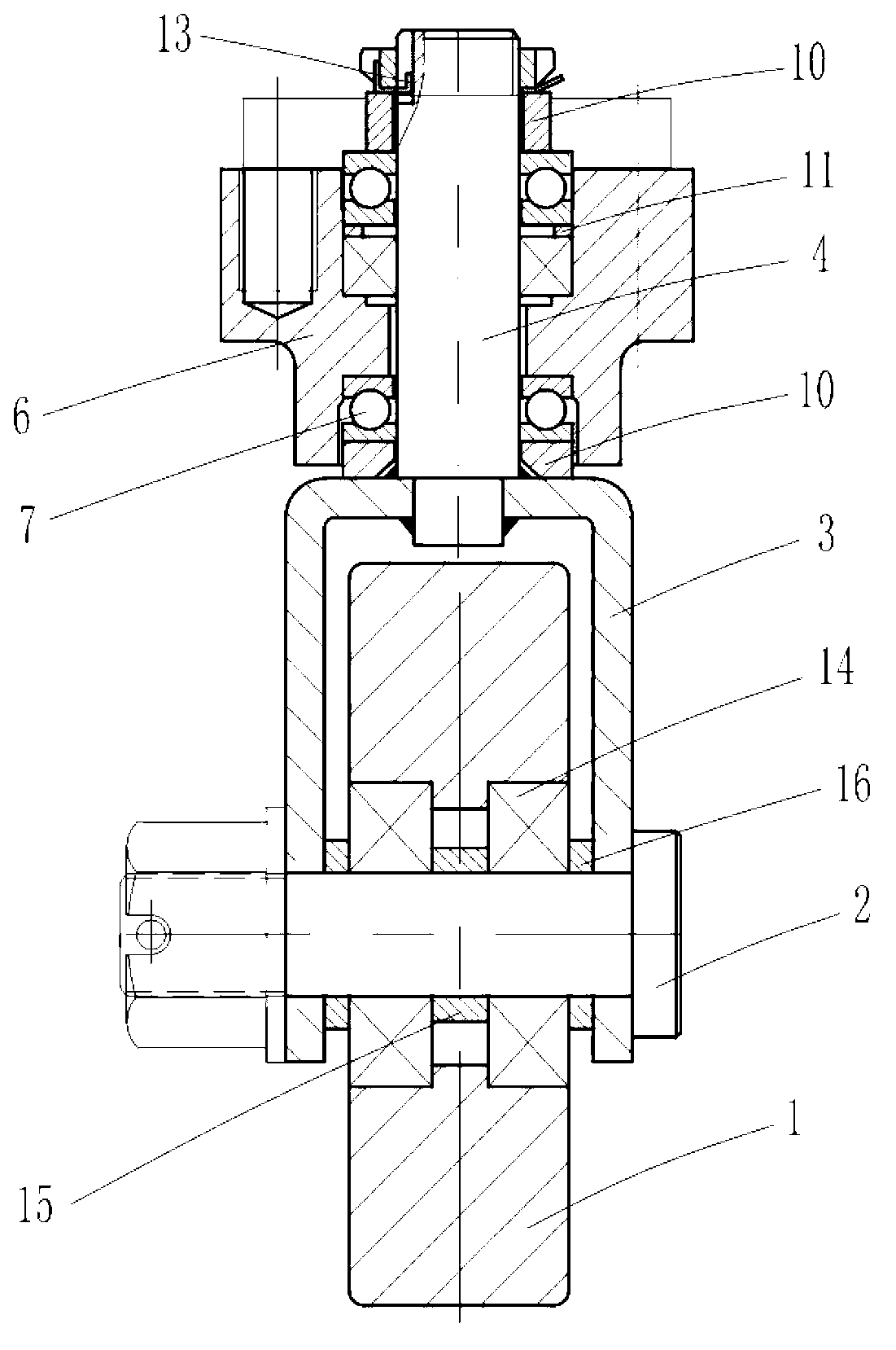

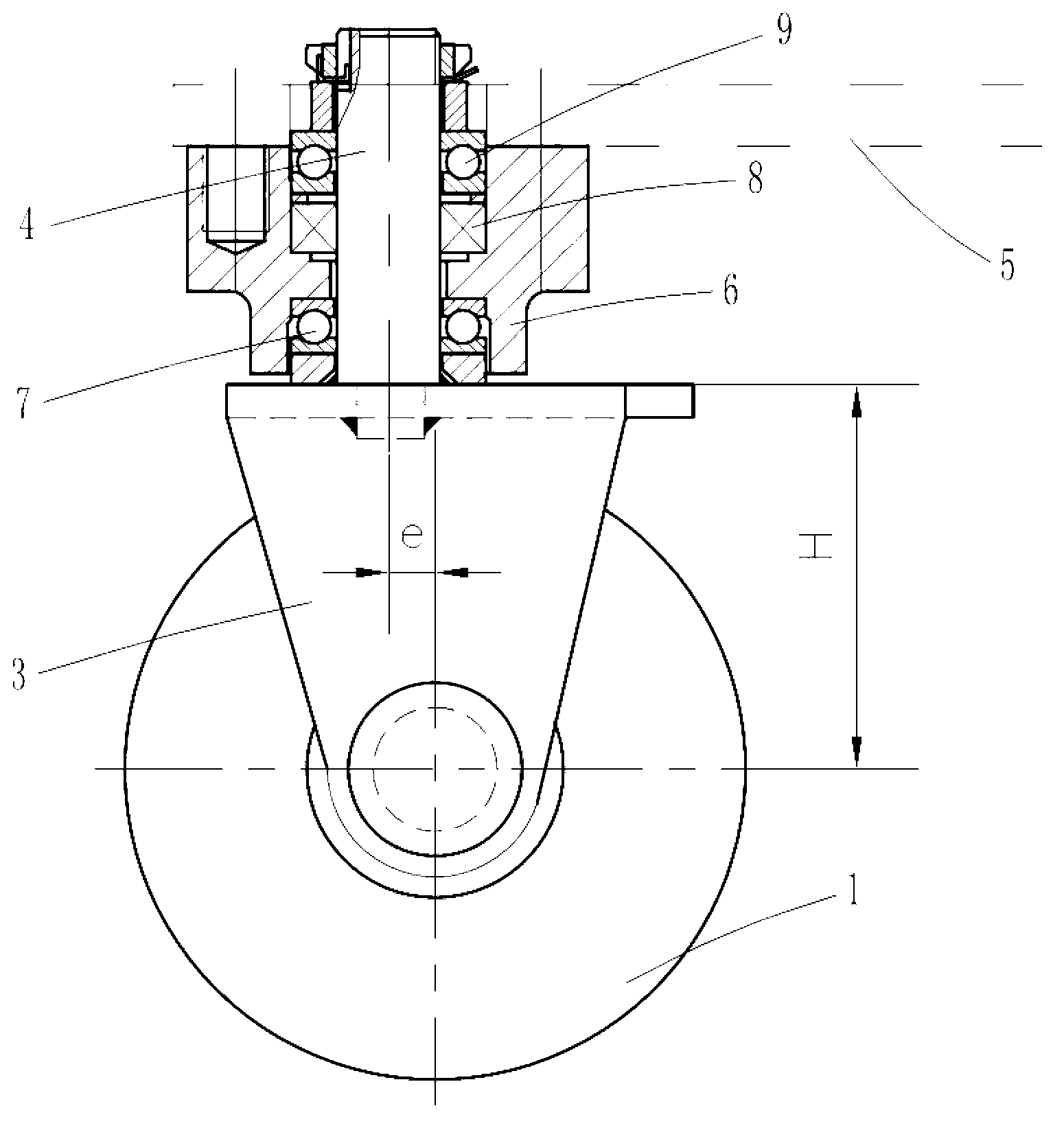

[0028] Example: take part in figure 1 , 2 The trolley of the commercial vehicle rear axle assembly line of the present embodiment self-corrects and guides the front wheel mechanism, which includes:

[0029] The front wheel 1 of the trolley is rotatably connected to the wheel shaft 2, and an inverted U-shaped seat 3 is flexibly connected to the wheel shaft 2; a rotating shaft 4 is fixed longitudinally on the top of the inverted U-shaped seat 3, and a connection seat that is fixedly connected with the bottom plate 5 of the trolley 6 Rotationally connected to the rotating shaft 4; in order to make the trolley automatically correct the position of the guiding front wheel so that it is parallel to the forward direction of the trolley, the vertical line where the center of the front wheel 1 is located and the center line of the rotating shaft 4 Non-coincident, that is, eccentric setting.

[0030] In the specific setting, the rotation connection mode between the rotating shaft 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com