Self-cleaning and heat-insulating coating and preparation method thereof

A technology for thermal insulation coatings and coatings, applied in the direction of coatings, etc., can solve the problems of affecting the decorative effect, the surface of thermal insulation coatings is easily polluted, etc., and achieve the effect of blocking heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

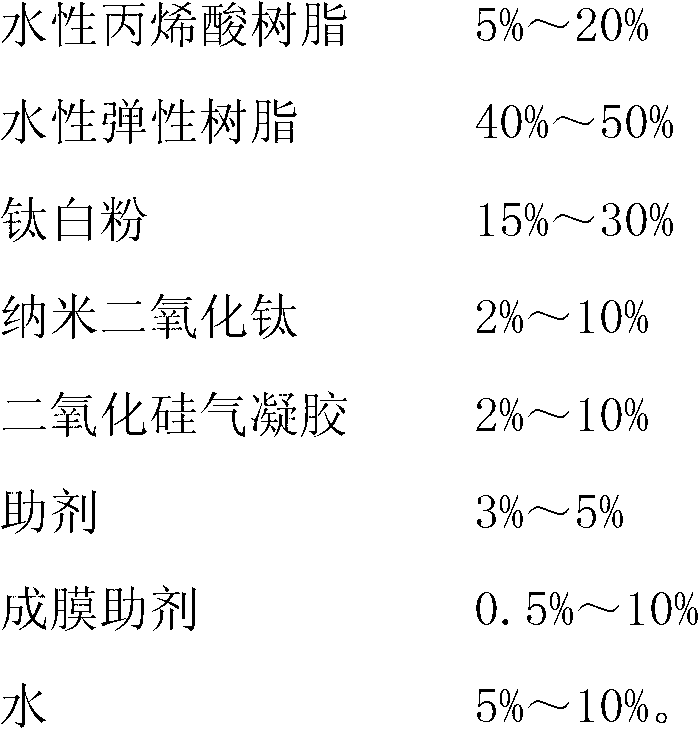

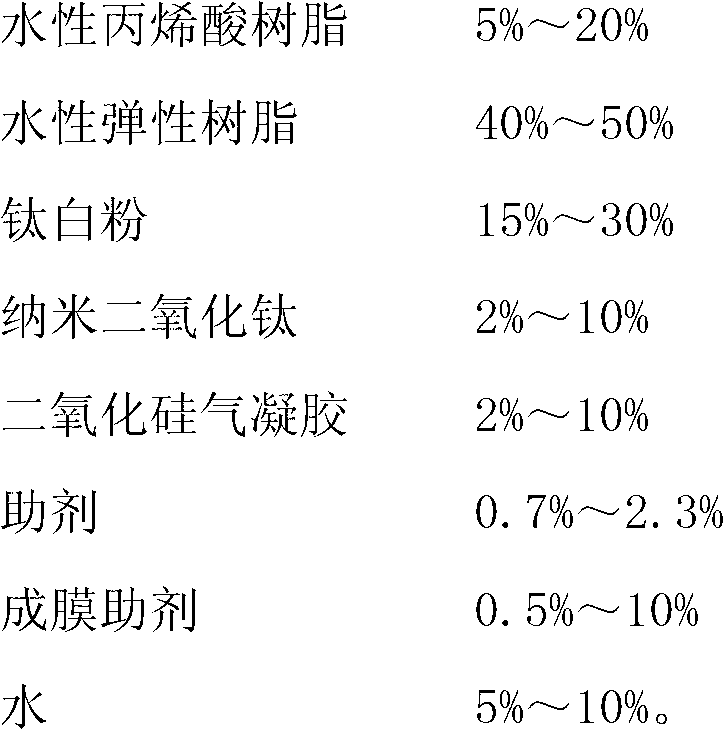

[0038] This embodiment provides a self-cleaning heat-insulating paint, which consists of the following components:

[0039] Water-based acrylic resin: 200 grams

[0040] Water-based elastic resin: 400 grams

[0041] Titanium dioxide: 210 grams

[0042] Nano Titanium Dioxide: 20g

[0043] Silica airgel: 20 grams

[0044] Additives: 17g

[0045] Coalescing aid 33 grams

[0046] Water: 100 grams;

[0047] The additives consist of 4 grams of SN5040, 5 grams of Defom W-0506, 2 grams of triton X-405, 3 grams of BYK-333, 1 gram of NanoBYK-3840 and 2 grams of Proxel GXL.

[0048] The preparation method of this coating is as follows:

[0049] First add 5g of water, 17g of additives, and 33g of film-forming additive propylene glycol butyl ether into the dispersion tank, stir at a speed of 300-400rmp for 20-30 minutes, then add 210g of titanium dioxide, and put Disperse the system until the fineness is less than 40um, then add the remaining 95g of water, then add water-based acry...

Embodiment 2

[0051] This embodiment provides a self-cleaning heat-insulating paint, which consists of the following components:

[0052] Water-based acrylic resin: 150 grams

[0053] Water-based elastic resin: 450 grams

[0054] Titanium dioxide: 170 grams

[0055] Nano Titanium Dioxide: 50g

[0056] Silica airgel: 50g

[0057] Additives: 23 grams

[0058] Coalescing aid 7 grams

[0059] Water: 100 grams;

[0060] The additives consist of 5 grams of Tamol-731, 5 grams of BYK-24, 3 grams of OP-10, 5 grams of Tech235, 3 grams of NanoBYK-3840 and 2 grams of Proxel GX.

[0061] The preparation method of this coating is as follows:

[0062] First add 5g of water, 23g of additives, and 7g of ethylene glycol as a film-forming aid into the dispersion tank, and stir for 20 to 30 minutes at a speed of 300 to 400rmp, then add 170g of titanium dioxide, and mix it at a speed of 800 to 1000rmp Disperse the system until the fineness is less than 40um, then add the remaining 95g of water, then add w...

Embodiment 3

[0064] This embodiment provides a self-cleaning heat-insulating paint, which consists of the following components:

[0065] Water-based acrylic resin: 50 grams

[0066] Water-based elastic resin: 500 grams

[0067] Titanium dioxide: 150 grams

[0068] Nano Titanium Dioxide: 100g

[0069] Silica Airgel: 100g

[0070] Auxiliary 15g

[0071] Coalescing aid 35 grams

[0072] Water: 50 grams;

[0073] The additives consist of 3 grams of Disper A40, 3 grams of BYK-24, 2 grams of Triton X-405, 2 grams of Tech235, 3 grams of NanoBYK-3840 and 2 grams of Mergal K10N.

[0074] The preparation method of this coating is as follows:

[0075] First add 2.5g of water, 15g of additives, and 35g of Texanol, a film-forming aid, into the dispersion tank, stir for 20-30 minutes at a speed of 300-400rmp, then add 150g of titanium dioxide, and put the system at a speed of 800-1000rmp Disperse until the fineness is less than 40um, then add the remaining 47.5g of water, then add water-based ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com