Low emissivity coating with indoor air purification function and preparation method thereof

A technology for indoor air and low radiation, applied in the field of low-emissivity paint and its preparation, to achieve the effect of purifying indoor air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

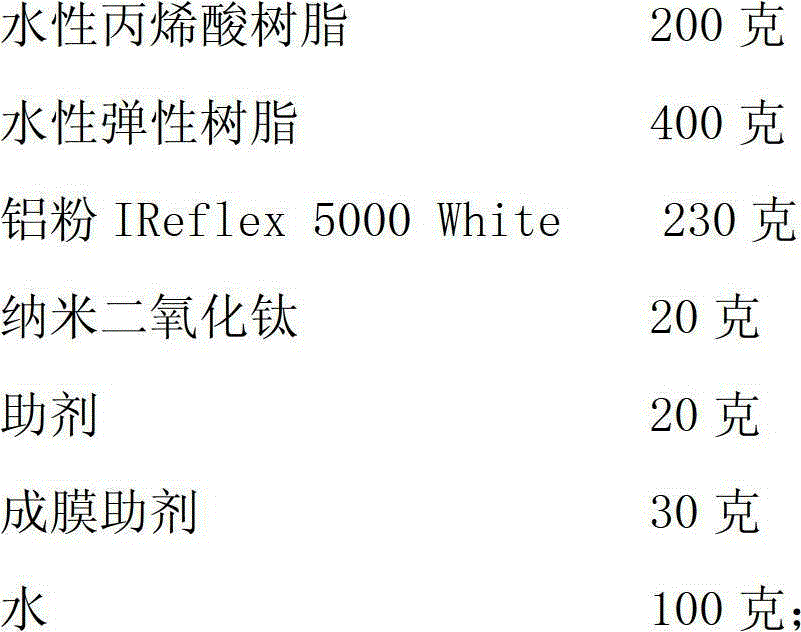

[0041] This embodiment provides a low emissivity coating with indoor air purification function, which is composed of the following components:

[0042]

[0043] Among them, the additives consist of 5 grams of SN-5029, 5 grams of SN-319, 3 grams of BYK-346, 5 grams of TT-93510 and 2 grams of ProxelGXL;

[0044] The preparation method of this coating is as follows:

[0045] First add 5g of water, 20g of additives, and 30g of film-forming additives into the dispersion tank, stir for 20-30 minutes at a speed of 300-400rmp, then add 230g of aluminum powder, and disperse the system at a speed of 800-1000rmp to The fineness is less than 40um, then add the remaining 95g of water, then add 200g of water-based acrylic resin, 400g of water-based elastic resin, and 20g of nano-titanium dioxide, and continue to disperse for 10 minutes to obtain a low-emissivity coating with indoor air purification function.

Embodiment 2

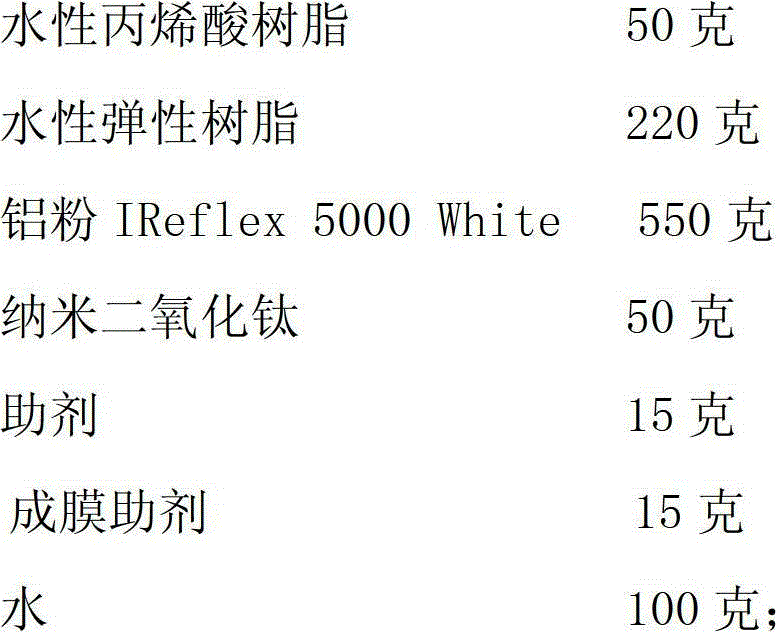

[0047] This embodiment provides a low emissivity coating with indoor air purification function, which is composed of the following components:

[0048]

[0049] Among them, the additives consist of 3 grams of Tamol-731, 4 grams of BYK-24, 3 grams of BYK-346, 4 grams of TT-935 and 1 gram of KATHONLXE;

[0050] The preparation method of this coating is as follows:

[0051] First add 5g of water, 15g of additives, and 15g of film-forming additives into the dispersion tank, stir at a speed of 300-400rmp for 20-30 minutes, then add 550g of aluminum powder, and disperse the system at a speed of 800-1000rmp When the fineness is less than 40um, add the remaining 95g of water, then add 50g of water-based acrylic resin, 220g of water-based elastic resin, and 50g of nano-titanium dioxide, and continue to disperse for 10 minutes to obtain a low-emissivity coating with indoor air purification function.

Embodiment 3

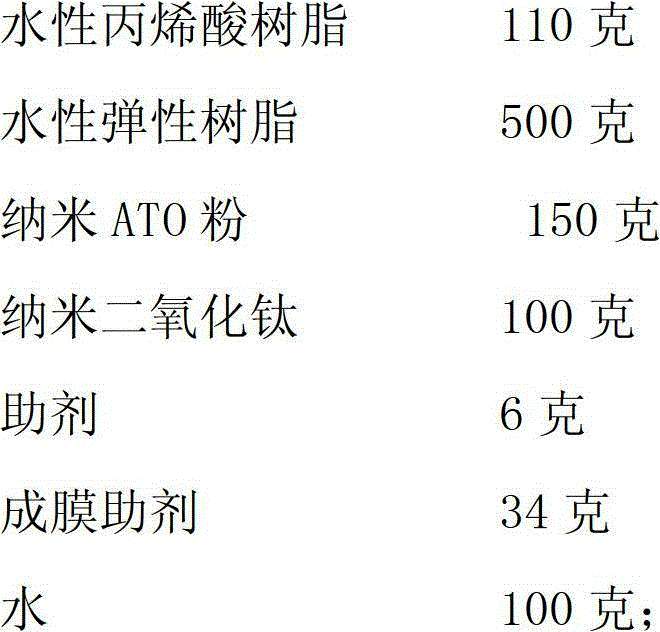

[0053] This embodiment provides a low emissivity coating with indoor air purification function, which is composed of the following components:

[0054]

[0055] Among them, the additives consist of 1 gram of Tamol-731, 1 gram of BYK-24, 1 gram of BYK-346, 2 grams of TT-935 and 1 gram of KATHONLXE;

[0056] The preparation method of this coating is as follows:

[0057] First add 5g of water, 6g of additives, and 34g of film-forming additives into the dispersion tank, stir at a speed of 300-400rmp for 20-30 minutes, then add 150g of nano-ATO powder, and mix the system at a speed of 800-1000rmp Disperse until the fineness is less than 40um, then add the remaining 95g of water, then add 110g of water-based acrylic resin, 500g of water-based elastic resin, and 100g of nano-titanium dioxide, and continue to disperse for 10 minutes to obtain a low-emissivity coating with indoor air purification function.

[0058] In summary, the coating provided by the embodiment of the present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com