Piston rapid aluminum oxidation single machine

An aluminum oxidation and piston technology, which is applied in the field of rapid aluminum oxidation of pistons, can solve the problems that the oxidized surface of the piston cannot reach the ideal quality, the flow rate of the bath liquid cannot be automatically monitored, and the oxidation effect cannot be obtained, so as to prevent electric shock accidents, Reduce reaction time, with accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

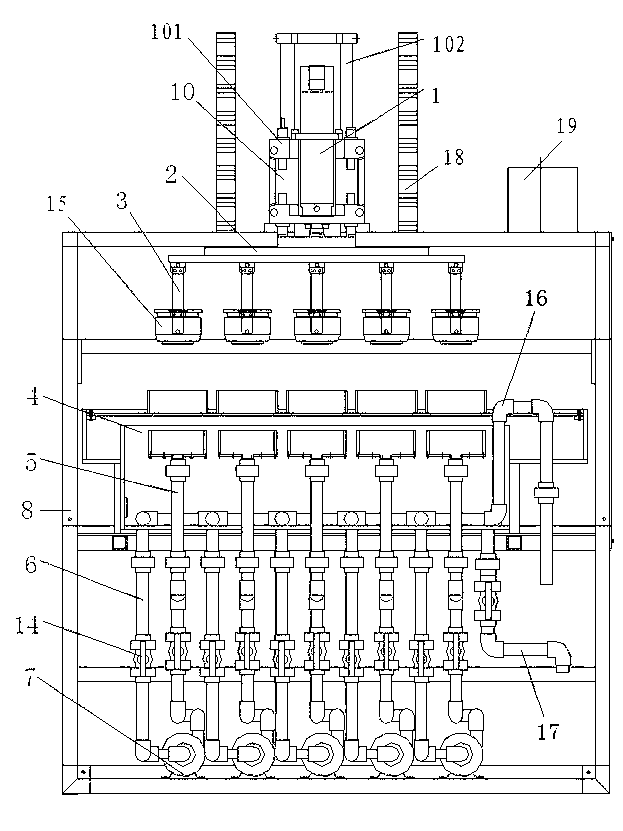

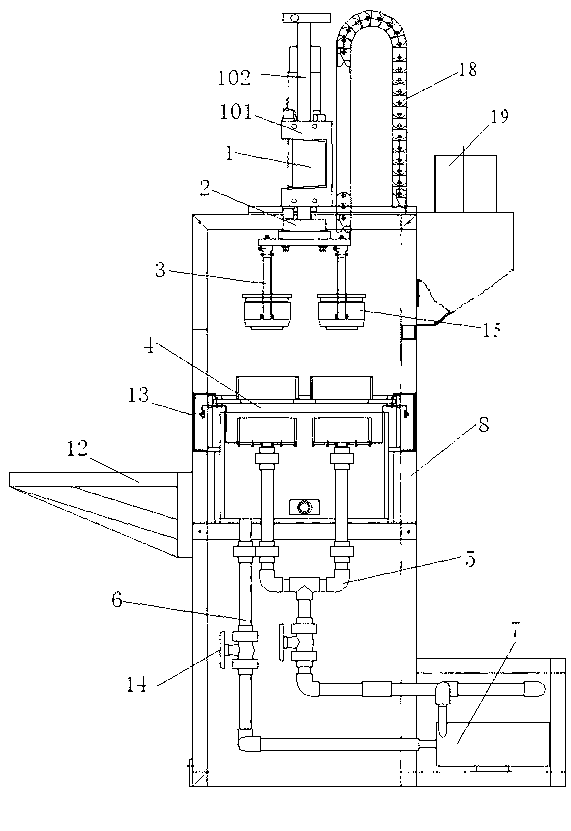

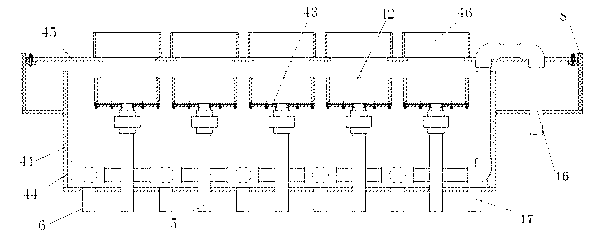

[0029] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0030] According to an embodiment of the present invention, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a piston rapid aluminum oxidation stand-alone machine is provided.

[0031] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, this embodiment includes a lifting cylinder 1, a hanger mounting plate 2, a hanger 3, an anodic oxidation tank 4, a circulation liquid inlet pipe 5, a circulation liquid outlet pipe 6, a circulation pump 7, a frame 8, and a hanger installation plate Guiding device 10, front stage 12, electrode shield 13, valve 14, piston 15, total liquid inlet pipe 16, total liquid outlet pipe 17, tank chain 18 and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com