Drill pipe of engineering driller

A technology for engineering drilling rigs and drill pipes, which is applied in the direction of drill pipes, rotary drilling rigs, and drill pipes. Simplicity and the effect of shortening the construction schedule

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

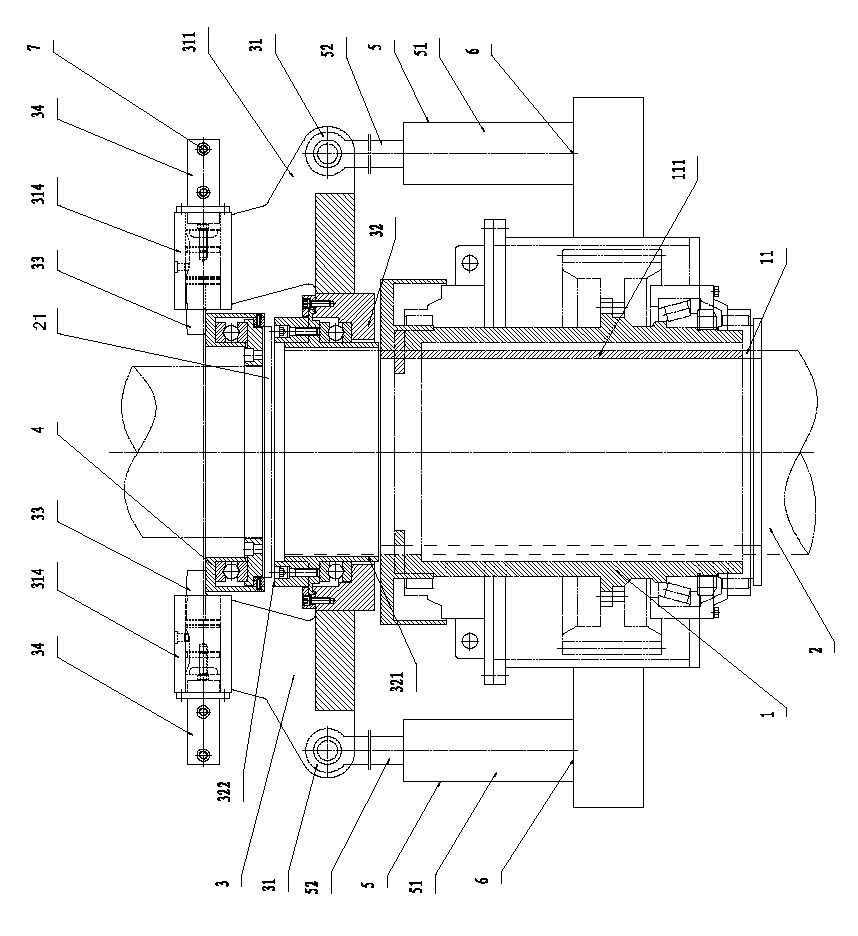

Method used

Image

Examples

Embodiment 1

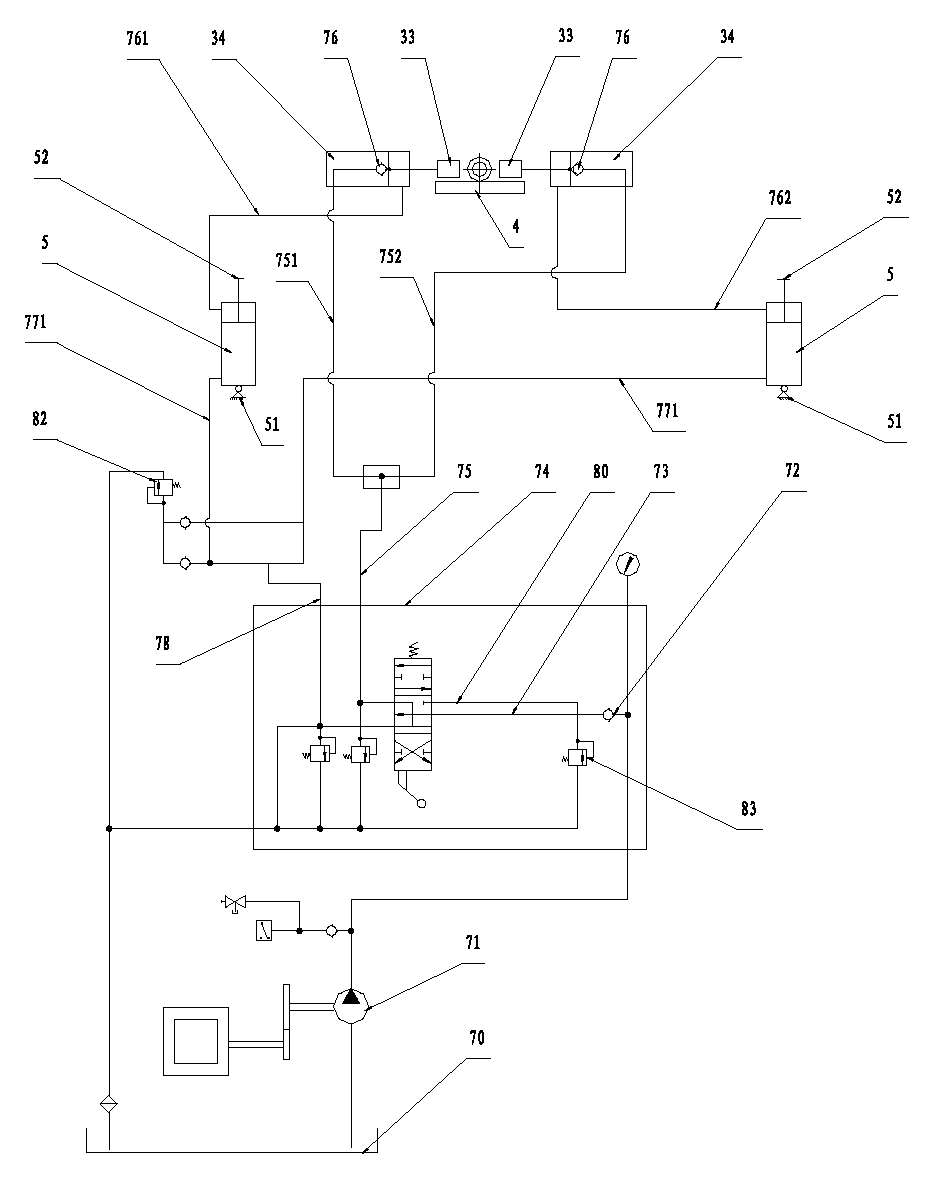

[0021] The manual reversing valve 74 moves upwards, the hydraulic pump 71 takes the hydraulic oil in the hydraulic oil tank 70, passes through the first check valve 72, the oil inlet pipe 73 and the manual reversing valve 74, the first working oil pipe 75, and the first oil distribution pipe 751 2. The second oil distribution pipe 752 provides hydraulic oil to the large chambers of the two pressure rod cylinders 5, and the pressure rod 33 stretches out from the cylinder 314 to press the drill pipe fixing ring 4. When the pressure oil in the large chambers of the two pressure rod cylinders 5 reaches the first When the second one-way valve 76 opens the pressure, the hydraulic oil enters the small cavity of the two lift cylinders 5 through the third oil distribution pipe 761 and the fourth oil distribution pipe 762, and the piston rod 52 of the lift cylinder 5 shrinks and pulls down the press frame 3, and 2 Drill down and excavate under pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com