Software compensation type all-temperature SF 6 gas density relay check device

A density relay, gas density technology, applied in measuring devices, temperature compensation modification, instruments, etc., can solve the problems of poor accuracy, large temperature influence, inability to guarantee accuracy, etc., to achieve easy operation, ensure accuracy, and overcome errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

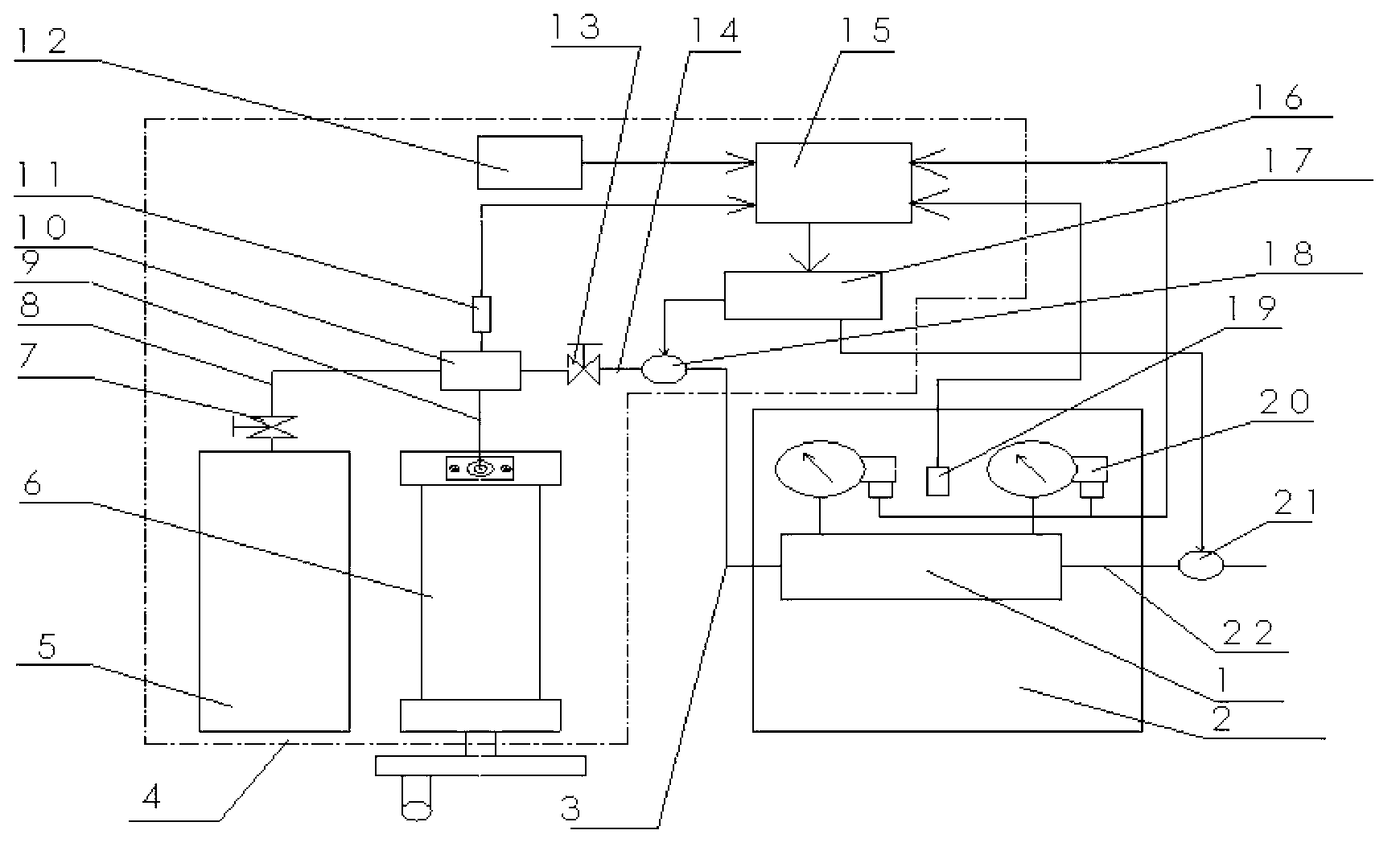

[0025] A full-temperature SF6 gas density relay calibration device using software compensation, including a housing 4 and a high and low temperature thermostat 2 outside the housing 4, such as figure 1 As shown: the high and low temperature constant temperature box 2 is equipped with a density relay 20 and a temperature sensor 19, and a SF6 gas storage tank 5 is fixed in the lower part of the casing 4, and the top of the gas storage tank 5 is connected with a four-way joint 10, and the four-way joint 10 The other three ends are respectively connected with a pressure sensor 11, a pressure regulating device 6 and a controller 17 for controlling the industrial control computer 15. The above-mentioned components are all connected by air pipes. The above-mentioned industrial control computer 15 is provided with a density relay 20 action signal input port, The relay action signal input port is connected to the contact connection line 16 .

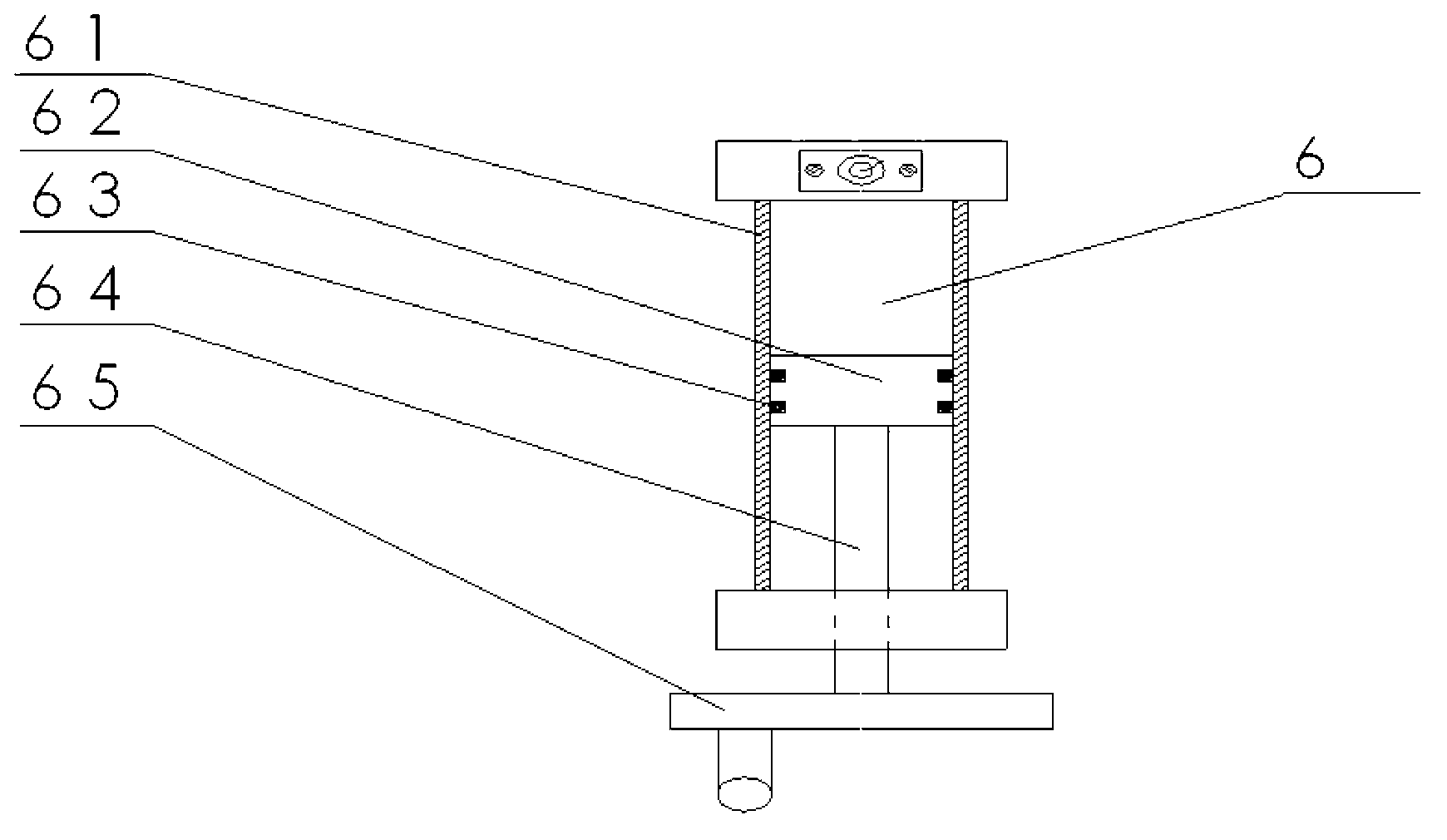

[0026]The density relay 20 is fixed on a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com