Drum-type washing machine

A technology of a drum type washing machine and a washing machine shell, which is applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of errors and foreign objects such as threads are easy to enter, and achieve the effect of stabilizing the water level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

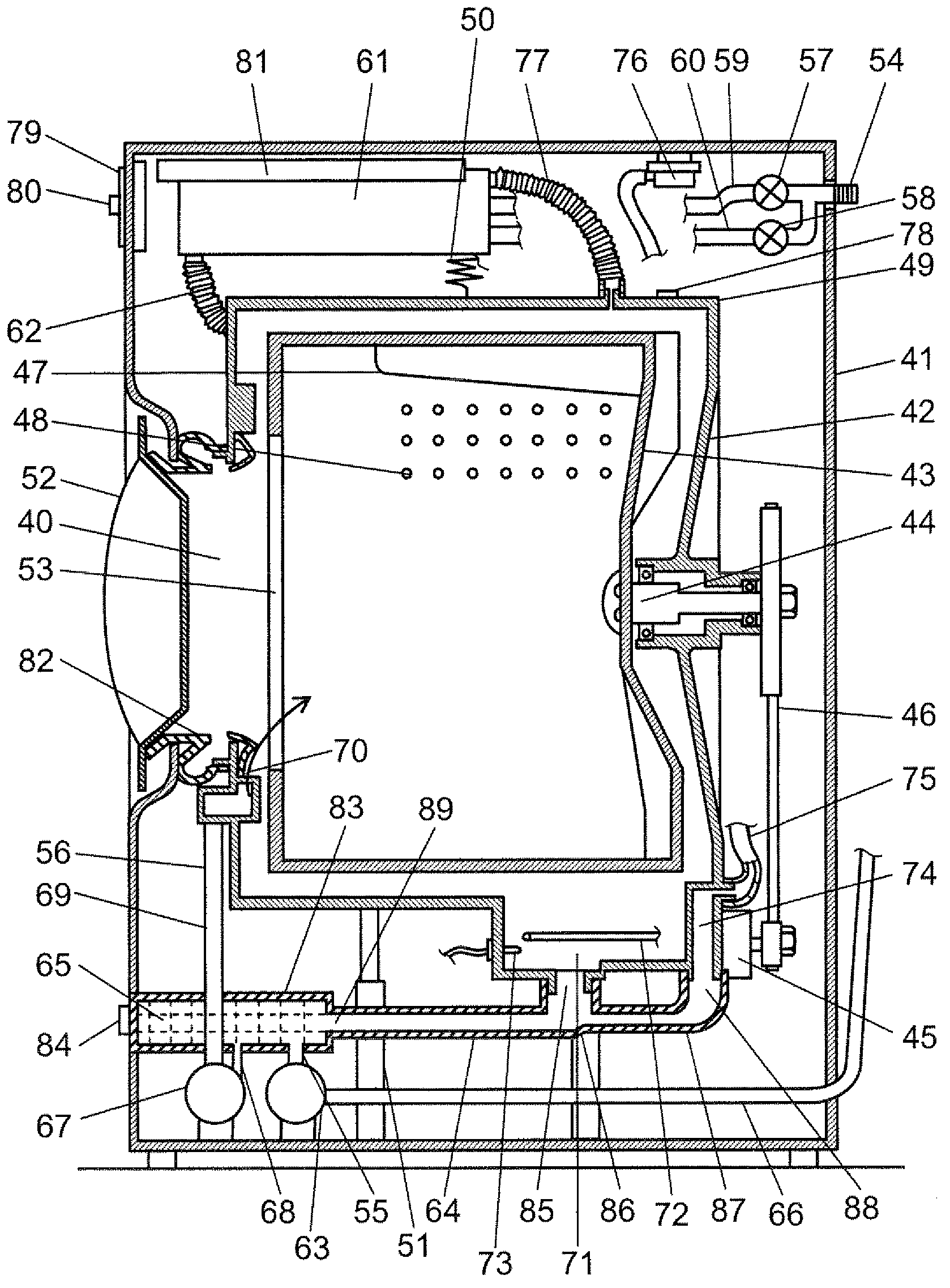

[0023] figure 1 It is a longitudinal cross-sectional view which shows the drum-type washing machine in embodiment of this invention.

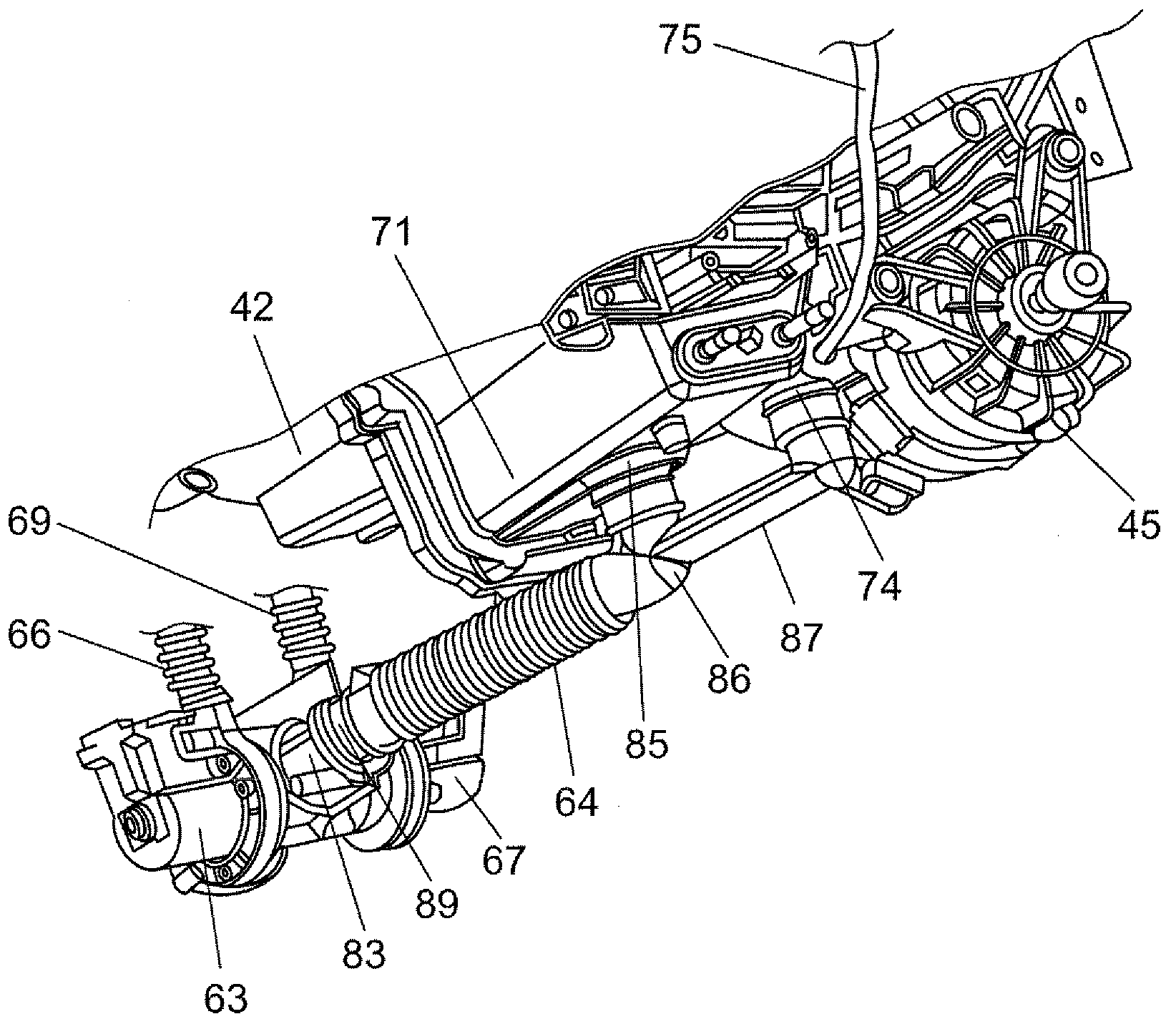

[0024] like figure 1 As shown, a swingable water tub 42 is arranged inside the washing machine casing 41 , and a rotatable rotary drum 43 is arranged in the water tub 42 . A rotation shaft (rotation center shaft) 44 arranged in the horizontal direction is provided at the rotation center of the rotary drum 43 . A motor 45 attached to the vicinity of the back side of the water tank 42 is connected to the rotating shaft 44 via a belt 46 . The rotational driving force of the electric motor 45 is transmitted to the rotating shaft 44 via the belt 46, and the rotating drum 43 is driven to rotate in the forward rotation and the reverse rotation direction. A plurality of protruding plates 47 (lifting ribs) for stirring the laundry (clothing) are provided on the inner wall surface of the rotary drum 43 . In addition, a plurality of water passage ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com