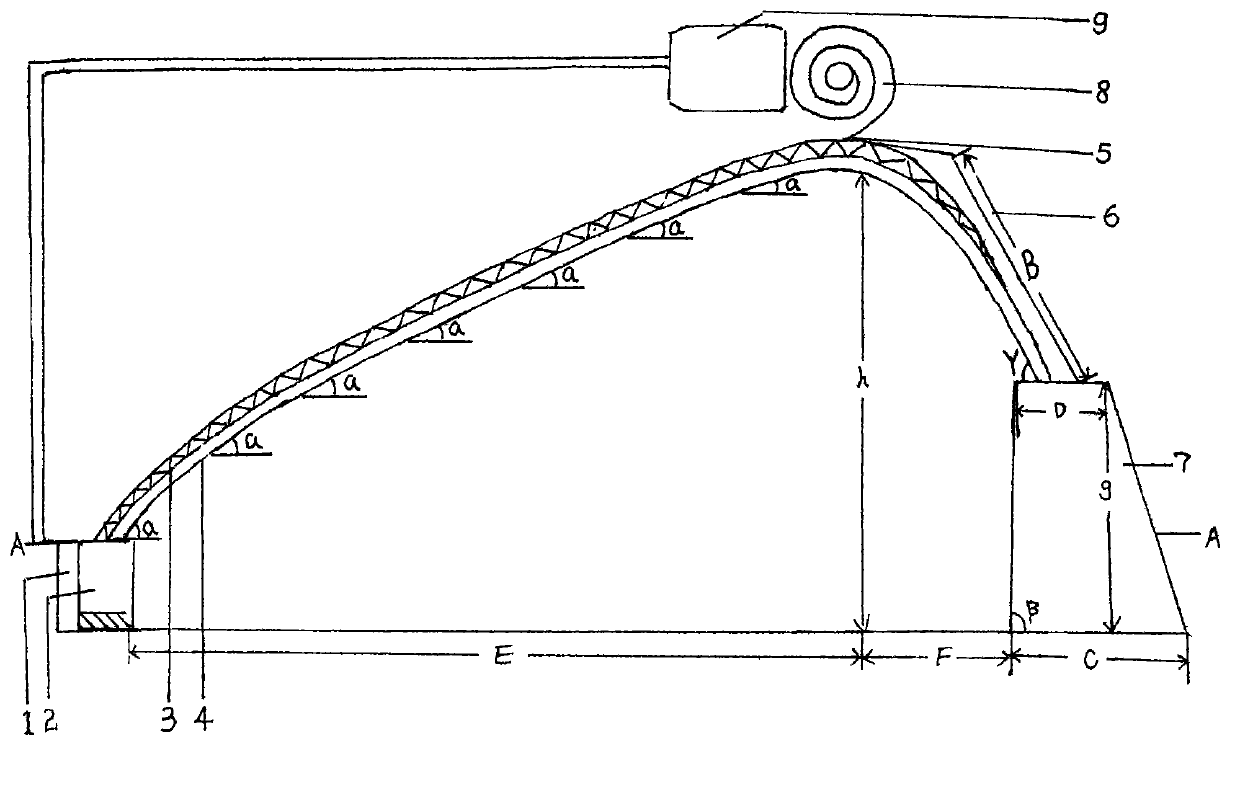

Northern vegetable sunlight greenhouse with three layers of greenhouse films

A technology for solar greenhouses and vegetables, applied in the field of solar greenhouses, can solve the problems of low thermal insulation performance and limitations of greenhouse lighting and thermal insulation capabilities, and achieve the effects of increasing thermal insulation capabilities, improving light receiving performance and thermal insulation capabilities, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] A three-layer shed film solar greenhouse for vegetables in the north, including a cold-proof layer (1), a front wall (2), a daylighting roof (3), an inner steel pipe layer (4), a shed apex (5), and a rear roof (6) , soil wall (7), quilt (8), electric roller shutter machine (9), the orientation of the solar greenhouse is 5°-8° to the west, and the front part of the front wall (2) is composed of plastic paper wrapped benzene board The cold-proof layer (1), the front wall (2) is a 240 brick wall with a height of 50 centimeters, the top of the front wall (2) and the top of the cold-proof layer (1) are flush with the ground plane, the daylighting roof (3) and the rear roof (6) The two ends of the scaffold are respectively fixed on the top of the front wall (2) and the top of the earth wall (7). The daylighting roof (3) is composed of inner, middle and outer steel pipe layers, and the outer layer is Φ6 national standard Galvanized steel pipes, the middle and inner layers are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com