Centrifugal casting method of stainless steel sealing rings

A technology of centrifugal casting and sealing ring, which is applied in the field of casting, can solve the problems of many casting defects and poor compactness of castings, and achieve the effects of compact structure, cost saving and good metallurgical quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

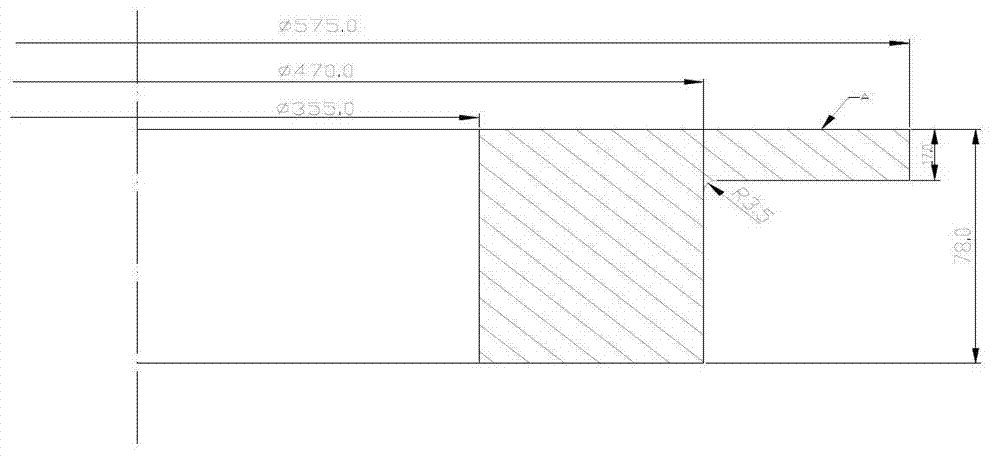

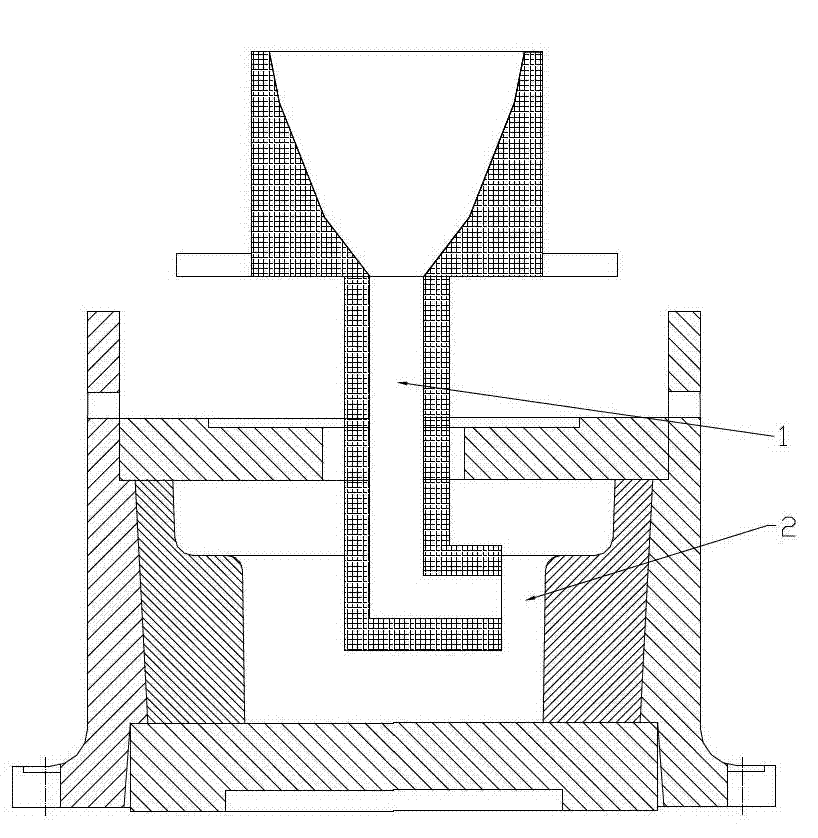

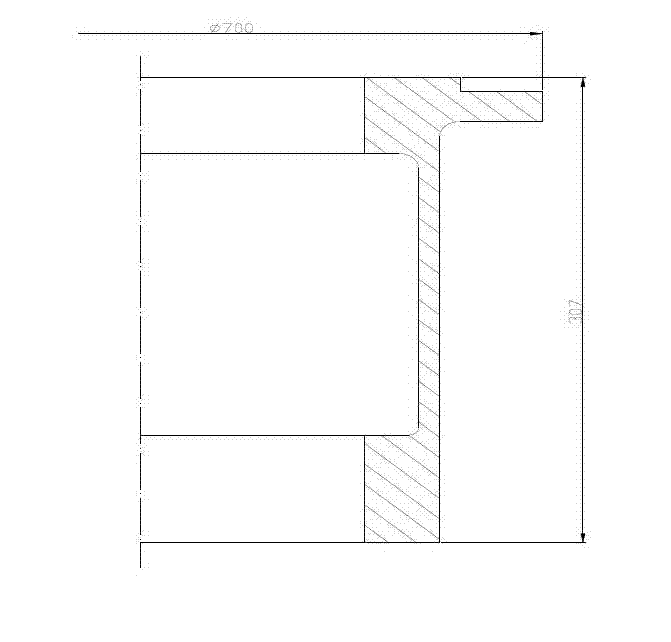

[0043] Casting material: duplex stainless steel casting weight 300Kg

[0044] Casting allowance: 6-8mm for the outer, upper and lower surfaces, and 20-40mm for the inner surface.

[0045] Centrifuge speed: 500 rpm

[0046] Pouring temperature: 1520°C--1540°C

[0047] Casting coating: 60% zircon powder + 40% silica sol (weight ratio)

[0048] Pouring system: runner diameter ф50mm, measuring direction elongation 100mm

[0049] Pouring time: 15-25 seconds

example 2

[0051] Casting material: Martensitic stainless steel Casting weight 350Kg

[0052] Casting allowance: 6-8mm for the outer, upper and lower surfaces, and 20-40mm for the inner surface.

[0053] Centrifuge speed: 550 rpm

[0054] Pouring temperature: 1580°C--1590°C

[0055] Casting coating: 60% zircon powder + 40% silica sol (weight ratio)

[0056] Pouring system: runner diameter ф50mm, measuring direction elongation 80mm

[0057] Pouring time: 18-28 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com