Friction welding repair process for waste pipes

A pipe friction and friction welding technology, which is applied in the direction of manufacturing tools, welding equipment, tubular objects, etc., can solve the problems of low repair rate and waste of resources for waste pipes, and achieve the effect of promoting circular economy, reducing resource waste, and improving repair rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

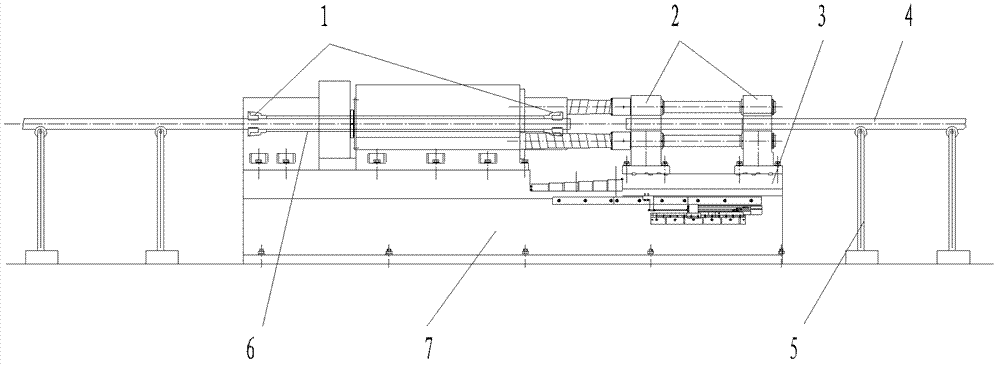

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, invention will be further described:

[0016] This process uses oil field waste pipelines as raw materials, uses friction welding technology to weld short tubes into standard tubes that can be used again, and maintains the good mechanical properties of the original pipelines. The specific process includes the pre-processing process, friction welding process and Subsequent processing;

[0017] The pre-processing process includes the following steps: cleaning→rough selection→sand blasting→shot blasting→straightening→flaw detection→tightening→end thread inspection→pressure testing→cutting the worn pipe body. The above process is the pre-processing process of friction welding, in which cleaning, sand blasting and shot blasting can effectively remove oil, rust and scale on the inner and outer surfaces of the pipeline, and rough selection, flaw detection and pressure testing can detect pipeline defects, leaving For the pipe bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com