Novel reciprocated type propelling device

A propulsion device, reciprocating technology, applied in the direction of non-rotating propulsion elements, etc., can solve the problems of complex manufacturing process, poor adaptability, high cost, etc., and achieve the effects of good balance, high propulsion efficiency and low working resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

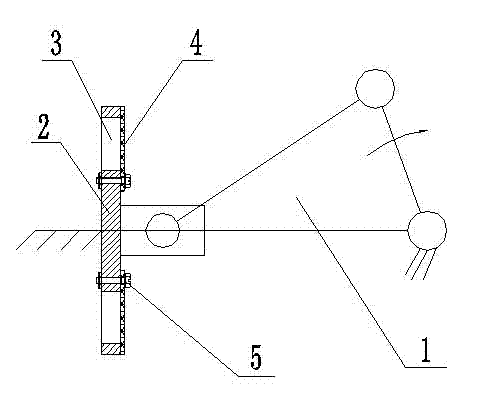

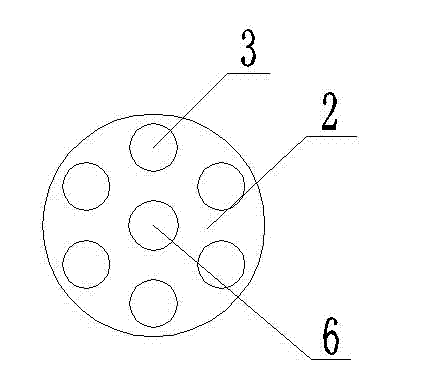

[0023] As shown in the figure, a new reciprocating propulsion device is mainly composed of a crank-slider mechanism 1 and a water pushing plate 2, and the slider of the crank-sliding block mechanism 1 is connected with the shaft hole 6 in the center of the water pushing plate 2 through a shaft. , the power is input to the crank of the crank-slider mechanism 1, and the rotation of the crank is converted into the linear reciprocating motion of the slider to drive the water pushing plate 2; the water pushing plate 2 is a disc-shaped structure, and a through circle The hole-shaped water flow channel 3 is also provided with a rubber pad 4 on the water pushing plate 2, and the rubber pad 4 is fixed by a bolt 5 on the edge of the water flow channel 3 and covers one end of the water flow channel 3;

[0024] There are multiple water flow channels 3, which are uniformly distributed around the center of the water pushing plate 2, and the number and radius of the water flow channels 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com