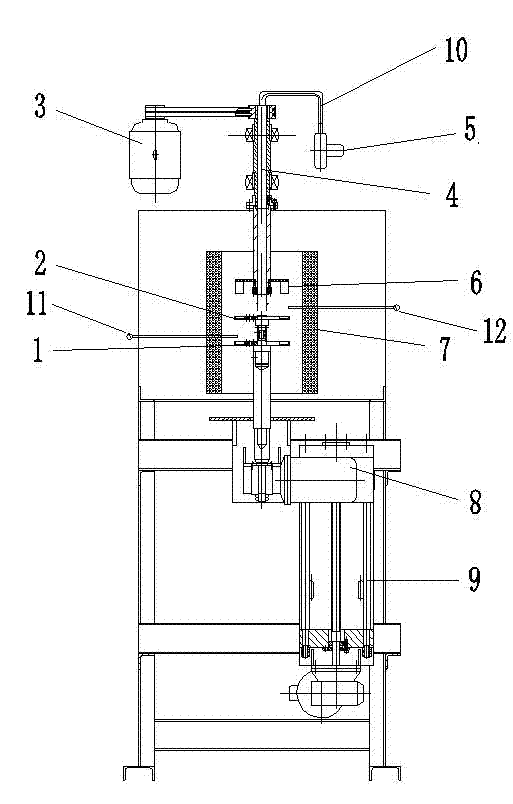

Optical glass rapid quenching furnace

A technology of optical glass and quenching furnace, which is applied in the field of optical glass quenching, to achieve the effect of improving the uniformity of temperature field, shortening the quenching cycle, and uniform temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

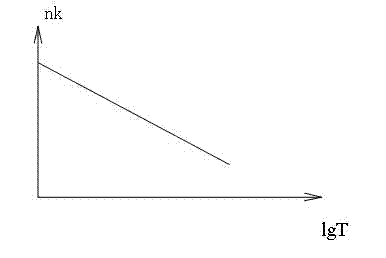

Problems solved by technology

Method used

Image

Examples

Embodiment 1

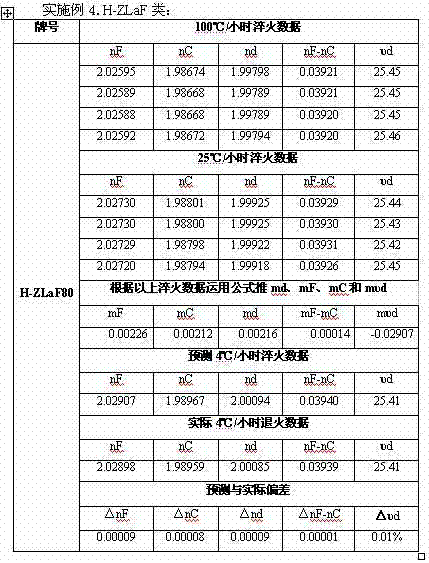

[0019] Example 1. H-ZK class:

[0020]

[0021]

[0022]

[0023]

[0024]

[0025] Note: nF, nC, nd, nF-nC, υ d represent respectively: the refractive index of the hydrogen blue line F, the refractive index of the hydrogen red line C, the refractive index of the helium yellow line d, the central dispersion, and the dispersion coefficient (that is, the Abbe number);

[0026] mF, mC, md, mF-mC, mυd Respectively: the refractive index annealing constant of the hydrogen blue line F, the refractive index annealing constant of the hydrogen red line C, the refractive index annealing constant of the helium yellow line d, the annealing constant of the middle dispersion, and the annealing constant of the dispersion coefficient (that is, the Abbe number);

[0027] △nF, △nC, △nd, △nF-nC, △υd Respectively: the difference in refractive index of the hydrogen blue line F, the refractive index difference of the hydrogen red line C, and the helium yellow line d in the case o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com