Pressure difference measuring system of automobile postprocessor

A post-processor and measurement system technology, applied in the field of pressure difference signal acquisition system, can solve problems such as pressure detection of post-processor system, and achieve the effect of stable structure and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

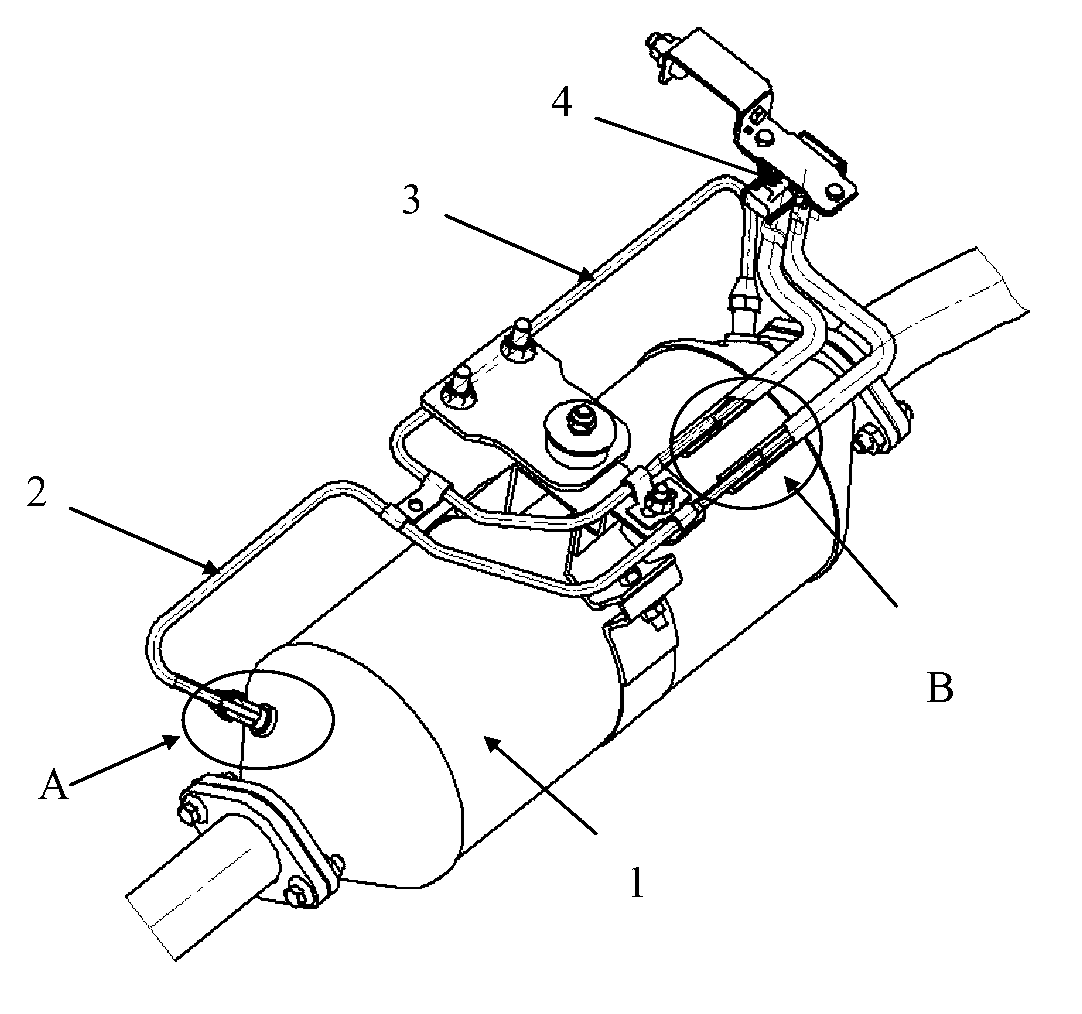

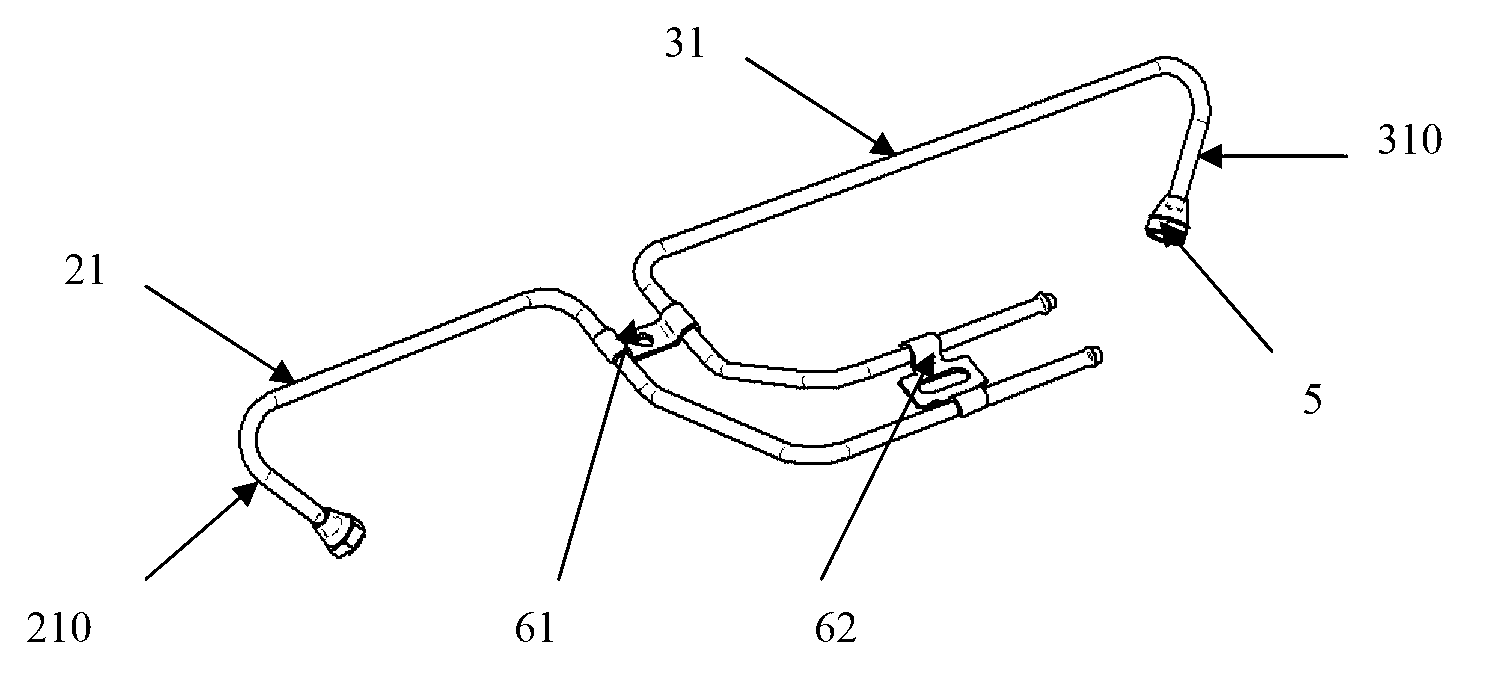

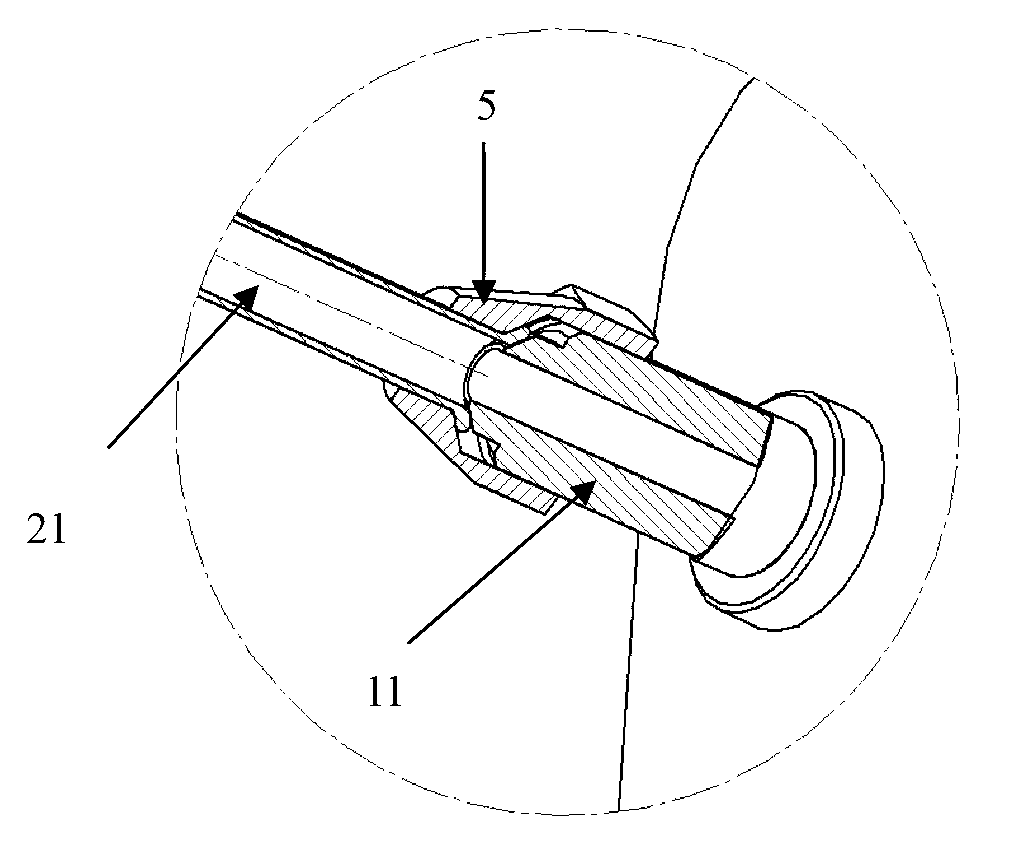

[0027] figure 1 It is a three-dimensional assembly diagram of an embodiment of the present invention. like figure 1 As shown, the post-processor pressure difference measurement system includes a front air intake pipe 2, a rear air intake pipe 3, and a pressure sensor 4; one end of the first steel pipe 21 of the front air intake pipe 2 is connected to the air intake end of the post-processor 1, and the other end is inserted into the first Flexible hose 22, the other end of the first flexible hose 22 is connected to the pressure sensor 4; one end of the second steel pipe 31 of the rear air intake pipe is connected to the exhaust end of the afterprocessor 1, and the other end is inserted into the second flexible hose 32, the second flexible hose 32 other ends are connected with pressure sensor 4. Preferably, in this embodiment, the first st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com