Check drain valve of heat accumulator

A heat accumulator and drain valve technology, applied in valve details, valve device, valve operation/release device, etc., can solve the problems of air leakage, seal failure, waste heat recovery device failure in the drainage system, etc., and reduce the density of spheres , The effect of reliable sealing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

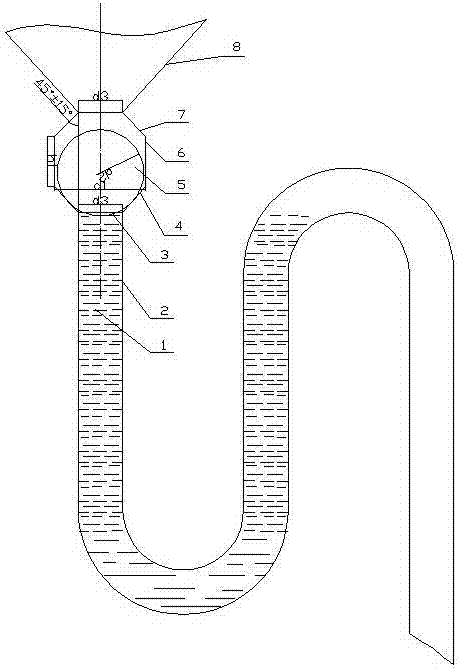

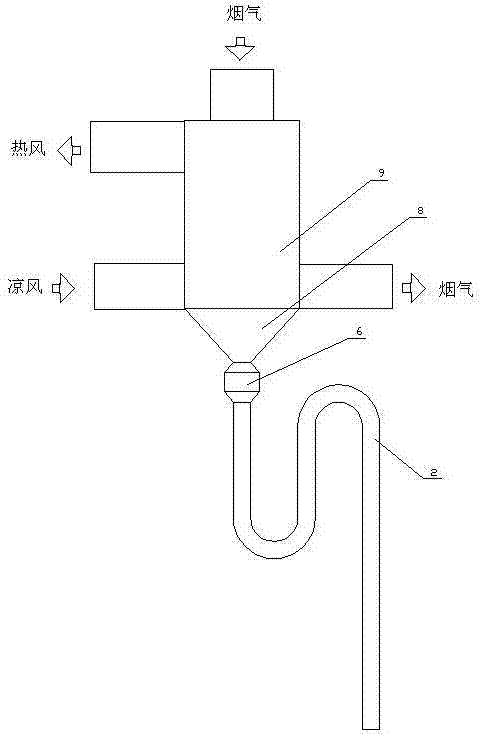

[0018] Such as figure 1 , 2 As shown, the upper and lower ends of the straight section sealing cylinder 6 are respectively sealed and connected with the upper cone section 7 and the lower cone section 4, and a floating ball 5 is arranged inside the straight section sealing cylinder 6. quality seal.

[0019] The upper end of the upper cone section 7 is provided with a liquid collecting cone 8 for connecting the heat accumulator 9 , and the lower cone section 4 is provided with a connection end for connecting the rotary liquid-sealed pipe 2 .

[0020] The height of the straight section sealing cylinder 6 is h 1 , the radius of the floating ball is d 2 , the diameter of the upper end of the upper cone section 7 and the diameter of the lower end of the lower cone section 4 are respectively d 3 , they satisfy the following conditions:

[0021] d 3 2 1 ;2d 2 ≥ h 1 ≥1.5d 2 ;d 1 2 = d 2 2 + d 3 2 .

[0022] Moreover, the inner cone angle of the upper cone section 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com