Twin-motor alternating-current driving system for electric fork-lift truck

An AC-driven, electric forklift technology, applied in the field of vehicle power systems, can solve problems such as low performance, inconvenient installation, and complex structure, and achieve the effects of easy layout and installation, reduced volume, and sensitive steering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

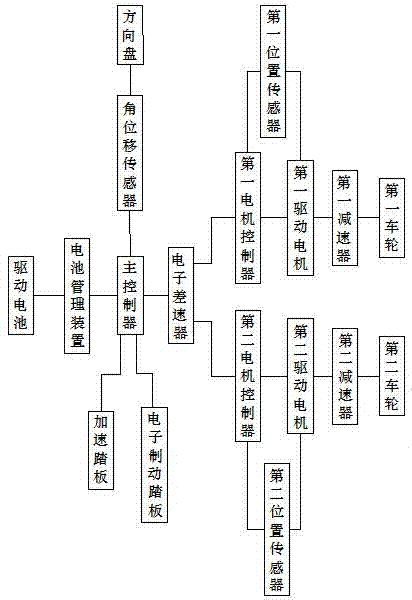

[0025] Such as figure 1 As shown, the electric forklift uses a dual-motor AC drive system, which includes a main controller, an accelerator pedal, an electronic brake pedal and a steering wheel connected to the main controller through a communication line, and the main controller is connected with the angular displacement sensor, the accelerator pedal, and the steering wheel. Electronic brake pedals, etc. collect action signals, and the above-mentioned dual-motor AC drive system for electric forklifts also includes:

[0026] An electronic differential, the electronic differential is connected to the main controller through a communication line;

[0027] A first motor controller and a second motor controller, the first motor controller and the second motor controller are respectively connected to the electronic differential through a communication line;

[0028] a first drive motor and a second drive motor, the first drive motor is electrically connected to the first motor con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com