Piezoelectric ceramic material applicable to energy collecting devices and preparation method thereof

A technology of piezoelectric ceramics and energy harvesting, applied in the field of piezoelectric ceramic materials, can solve the problems of low performance that cannot meet the application requirements of energy harvesting devices, large-scale application, cumbersome manufacturing process, etc., to improve electromechanical conversion efficiency and significantly economical and social value, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

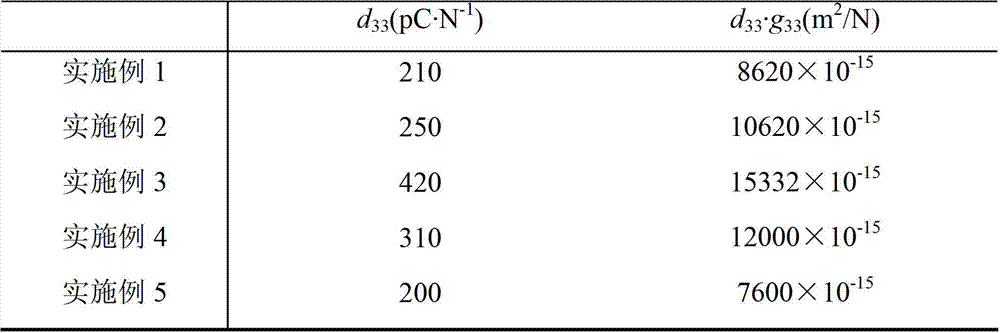

Embodiment 1

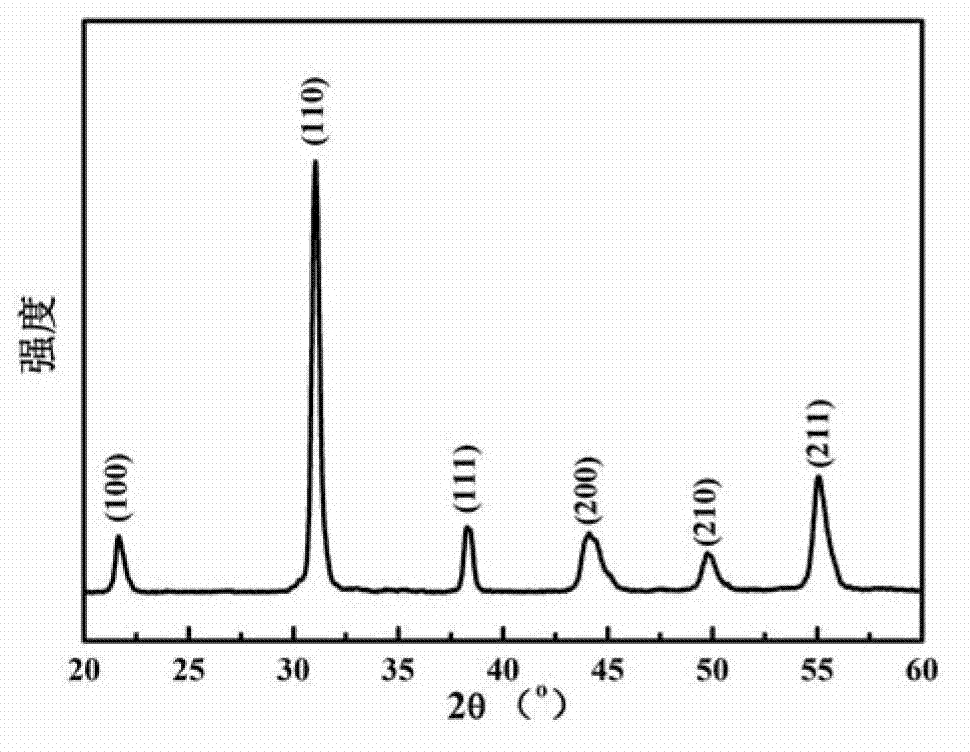

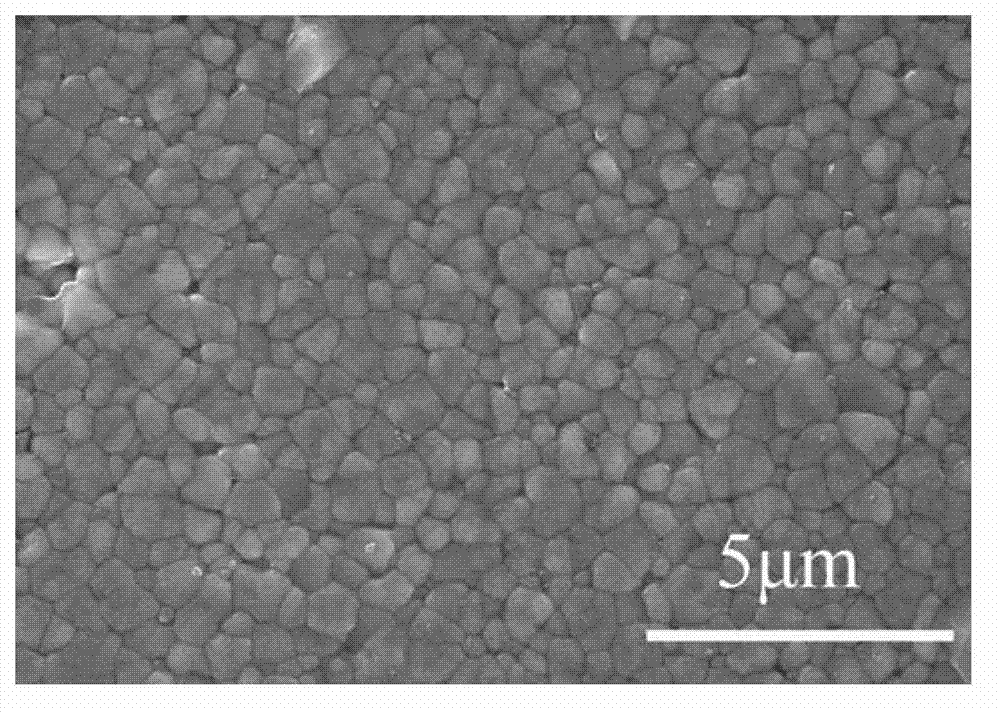

[0028] According to chemical formula Pb 0.9 Sr 0.1 (Zn 1 / 3 Nb 2 / 3 Zr 0.30 Ti 0.50 )O 3 Weighing ZnNb 2 O5, Pb 3 O4, ZrO 2 、TiO 2 and SrCO 3 , and ball milled in ethanol for 24 hours. After the mixture is dried, it is calcined at 850°C for 2 hours, ball milled in ethanol again, mixed according to the ratio of 10g powder and 1.5mL binder, and the molded product is pressed at 100MPa, and the binder is removed from the molded product at 560°C , and sintered at 1050°C for 2 hours to obtain ceramics.

Embodiment 2

[0030] According to chemical formula Pb 0.92 Sr 0.08 (Zn 1 / 3 Nb 2 / 3 Zr 0.35 Ti 0.45 )O 3 Weighing ZnNb 2 O5, Pb 3 O4, ZrO 2 、TiO 2 and SrCO 3 , and doped with 0.5wt% CoCO of the matrix material 3 , the calcination temperature is 900°C,

[0031] The sintering temperature is 1100°C. Others are with embodiment 1.

Embodiment 3

[0033] According to chemical formula Pb 0.95 Sr 0.05 (Zn 1 / 3 Nb 2 / 3 Zr 0.40 Ti 0.40 )O 3 Weighing ZnNb 2 O5, Pb 3 O4, ZrO 2 、TiO 2 and SrCO 3 , and doped with 0.8wt% CoCO of the matrix material 3 , the calcination temperature is 800°C,

[0034] The sintering temperature is 1000°C. Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com