Silicone rubber composite material with high mechanical-electrical conversion efficiency and preparation method thereof

A technology of composite materials and silicone rubber, which is applied in the field of silicone rubber composite materials with high electromechanical conversion efficiency and its preparation, and in the field of silicone rubber composite materials, can solve the problems of limited energy density and electromechanical conversion efficiency of composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

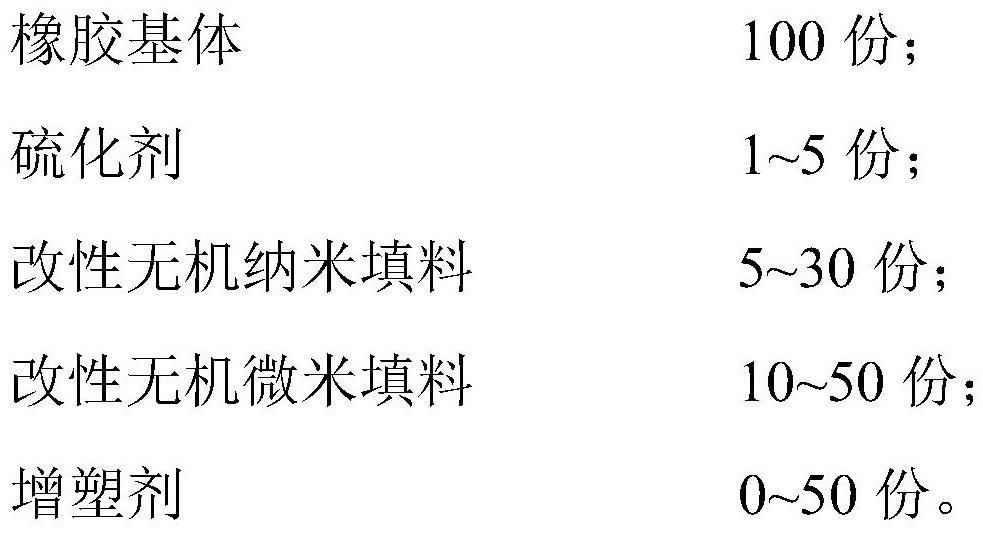

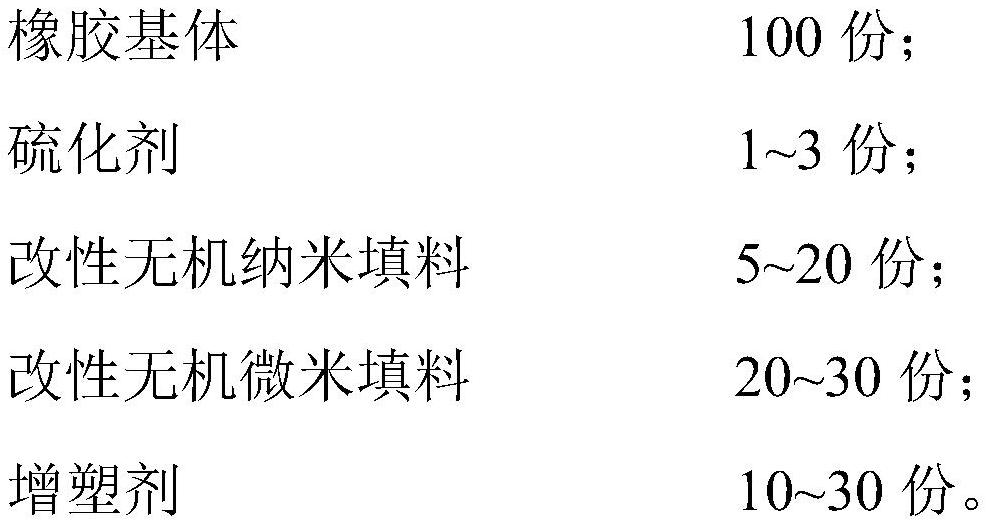

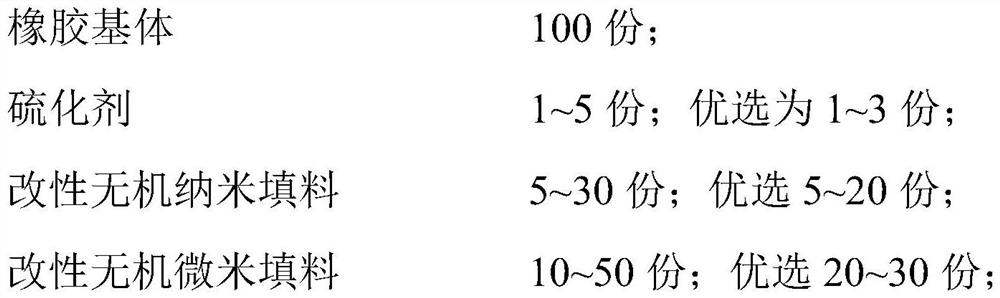

Method used

Image

Examples

Embodiment 1

[0040] The specific operation steps are: (1) use the silane coupling agent KH570 (γ-methacryloxypropyl) to modify the micro- and nano-scale inorganic fillers respectively (according to "Improved electromechanical properties of brominated butyl rubber filled with modified barium titanate." ("RSC Advances" 2017,7(59):37148-37157.) prepared), some functional groups of KH570 can react with the hydroxyl groups on the surface of the inorganic filler to obtain surface-modified modified inorganic fillers. (2) at room temperature, the methyl vinyl silicone rubber of 100 mass parts is plasticized on the Haake rheometer produced by Thermo Fisher Corporation, and then 5 mass parts of modified titanium dioxide with an average particle diameter of 30nm and 25 parts by mass of modified titanium dioxide with an average particle size of 2 μm were slowly added to the methyl vinyl silicone rubber several times, kneaded for 5 minutes to uniformly disperse the titanium dioxide, and finally 1 part b...

Embodiment 2

[0042] The preparation process is the same as in Example 1, except that the modified titanium dioxide with an average particle diameter of 30 nm is 10 parts by mass, the modified titanium dioxide with an average particle diameter of 2 μm is 20 parts by mass, and then the number of parts of methyl silicone oil added is 10 parts by mass . The test results are shown in Table 1.

Embodiment 3

[0044] The preparation process is the same as in Example 2, except that 20 parts by mass of modified titanium dioxide with an average particle diameter of 30 nm, 30 parts by mass of modified titanium dioxide with an average particle diameter of 2 μm, and 30 parts by mass of methyl silicone oil. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com