External electron donor component, alkene polymerization catalyst containing external electron donor component and application thereof

An external electron donor and olefin polymerization technology, which is applied in the application field of tactic polypropylene, random copolymer polypropylene and impact-resistant copolymer polypropylene, can solve the problems of inconvenience, low ethylene content, poor product performance, etc., and achieve product Excellent performance, high ethylene content, high isotactic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

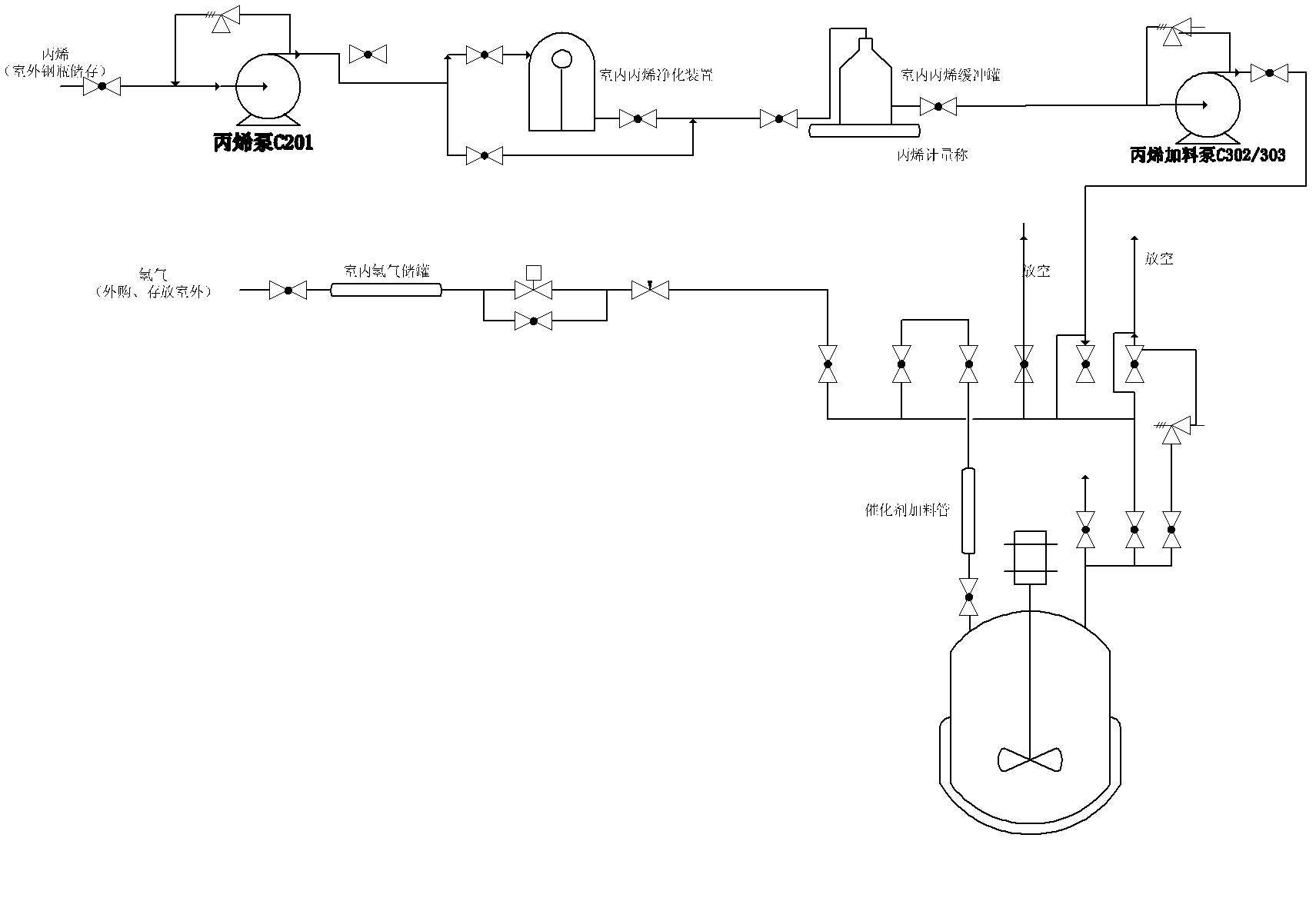

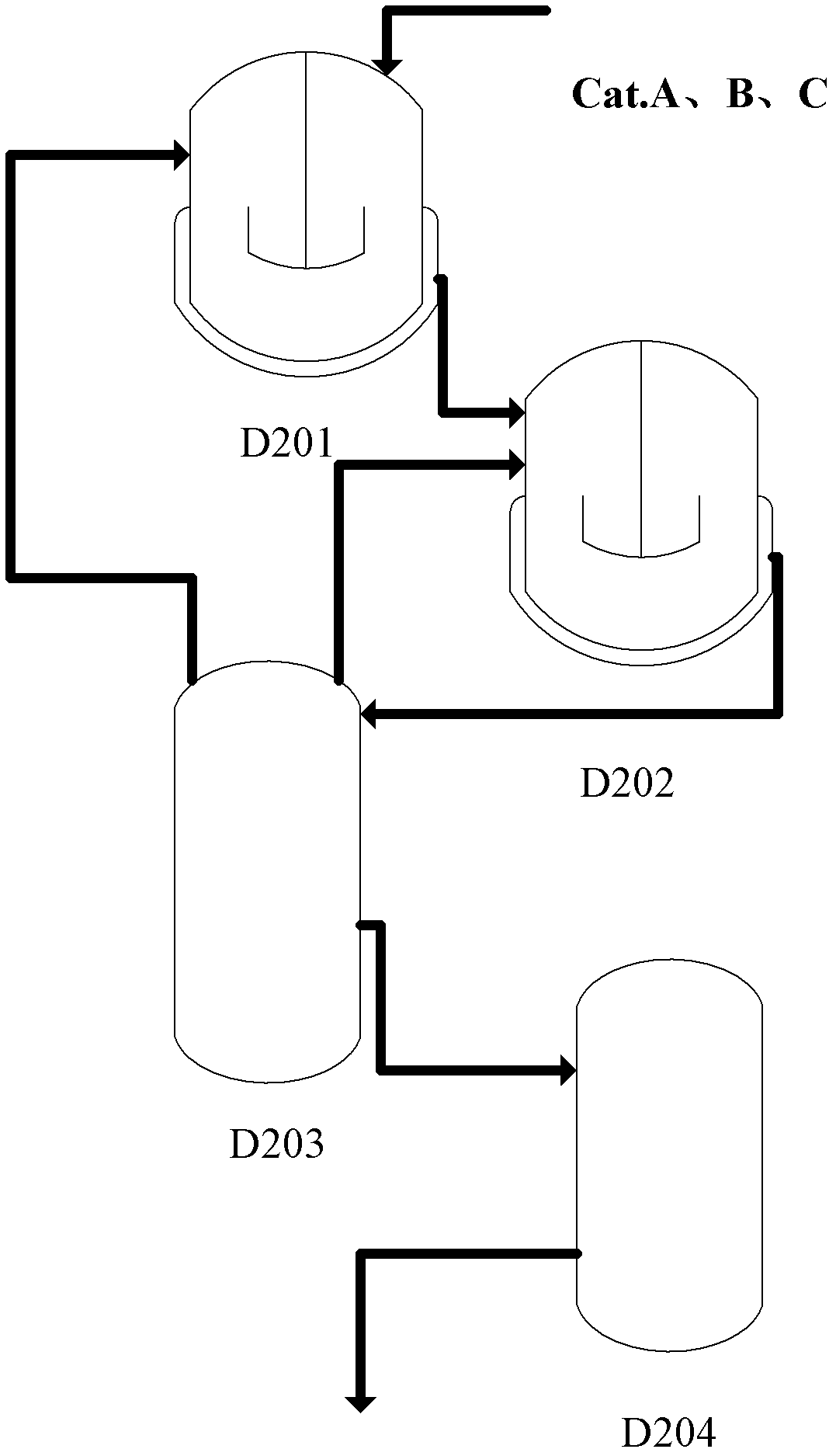

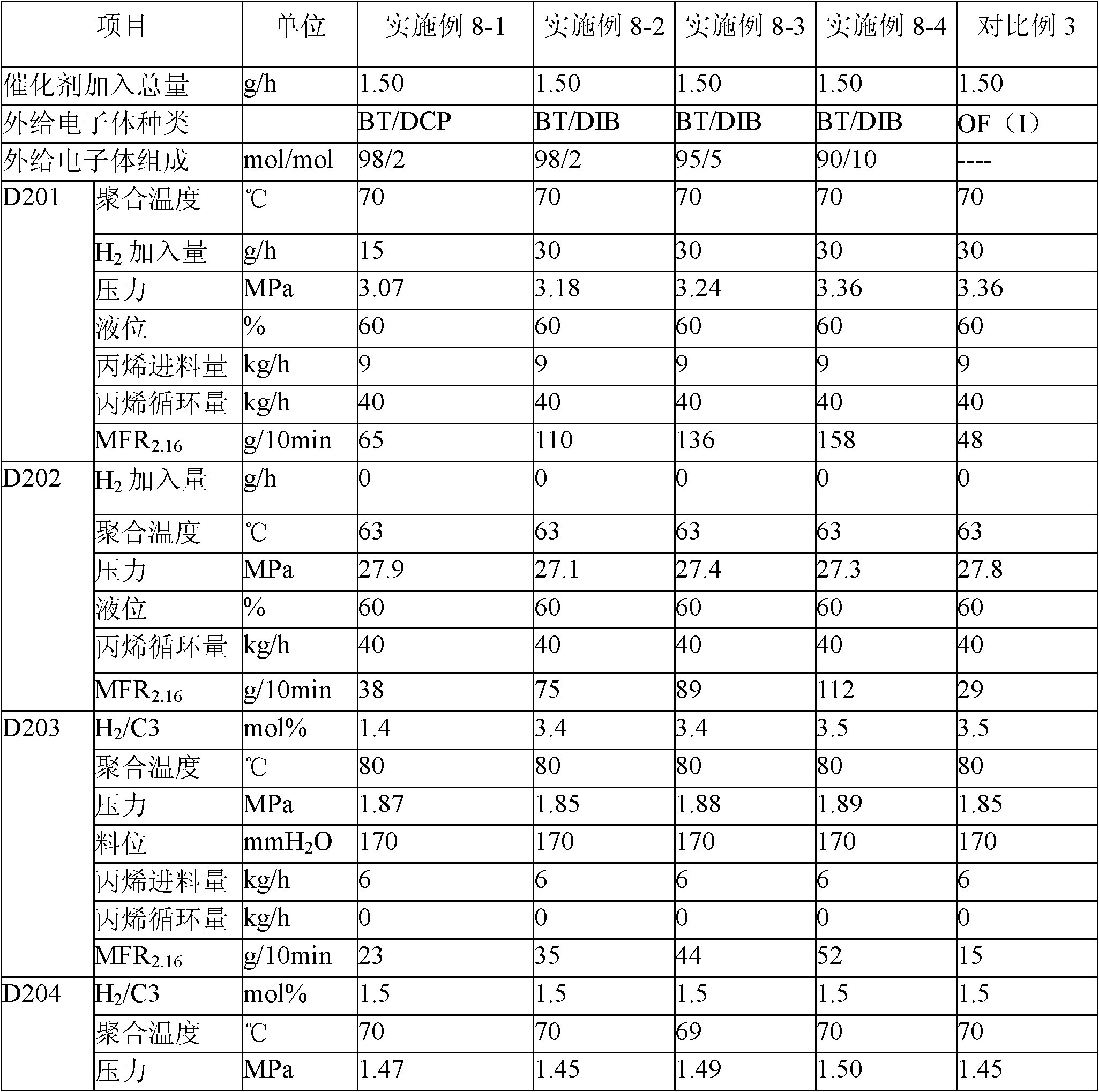

[0021] This embodiment is carried out in a 10L high-pressure polymerization kettle, and the reaction temperature and stirring speed are controlled by the DCS system. Firstly, the polymerization tank is purged with nitrogen, then components A, B, and C in the catalyst are added to the catalyst feeder under the protection of nitrogen, and the liquid propylene pressurized by the diaphragm pump is brought into the polymerization tank, and measured with an electronic balance. Control the excess of propylene to ensure that there is still propylene monomer in the reactor when the reaction ends. Then, hydrogen gas is introduced, and the hydrogen gas is measured by pressure difference. After the material is added, the temperature is raised rapidly, the temperature is controlled at 70±0.1°C, the stirring speed is 240 rpm, and the polymerization reaction time is 60 minutes. Finally, open the feeding valve to release the material, dry the material, weigh it, and analyze and test it. The s...

Embodiment 1-0

[0027] Example 1-0, the catalyst ratio is Al / Ti=100 / 1 (mol / mol), Si / Ti=10 / 1 (mol / mol), and the amount of hydrogen added is 5L;

[0028] Example 1-1, the catalyst ratio is Al / Ti=100 / 1 (mol / mol), Si / Ti=10 / 1 (mol / mol), and the amount of hydrogen added is 10L;

Embodiment 1-2

[0029] Example 1-2, the catalyst ratio is Al / Ti=100 / 1 (mol / mol), Si / Ti=5 / 1 (mol / mol), and the amount of hydrogen added is 15L;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com