Method for implementing seamless bicolor electroplating to plastic parts

A two-color electroplating, seamless technology, used in sputtering, ion implantation, vacuum evaporation, etc. The effect of convenient color, smooth and continuous surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

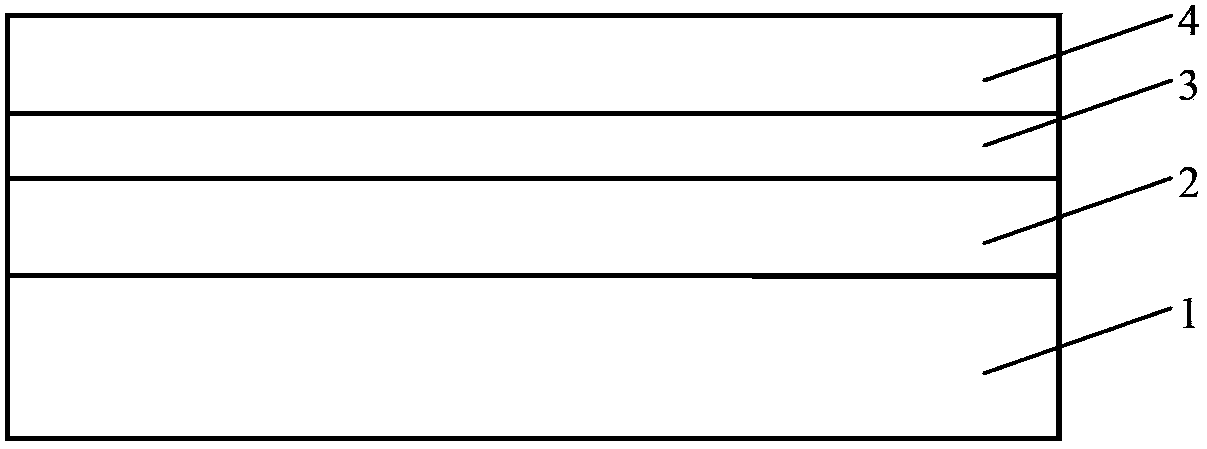

[0027] Example 1: A seamless ceramic white and gold faucet

[0028] 1) Spray the ceramic white high-gloss paint layer on the faucet first, and bake at 70°C for 30 minutes.

[0029] 2) Spray the workpiece treated in step 1) with a black peelable paint layer, and bake at 70°C for 20 minutes.

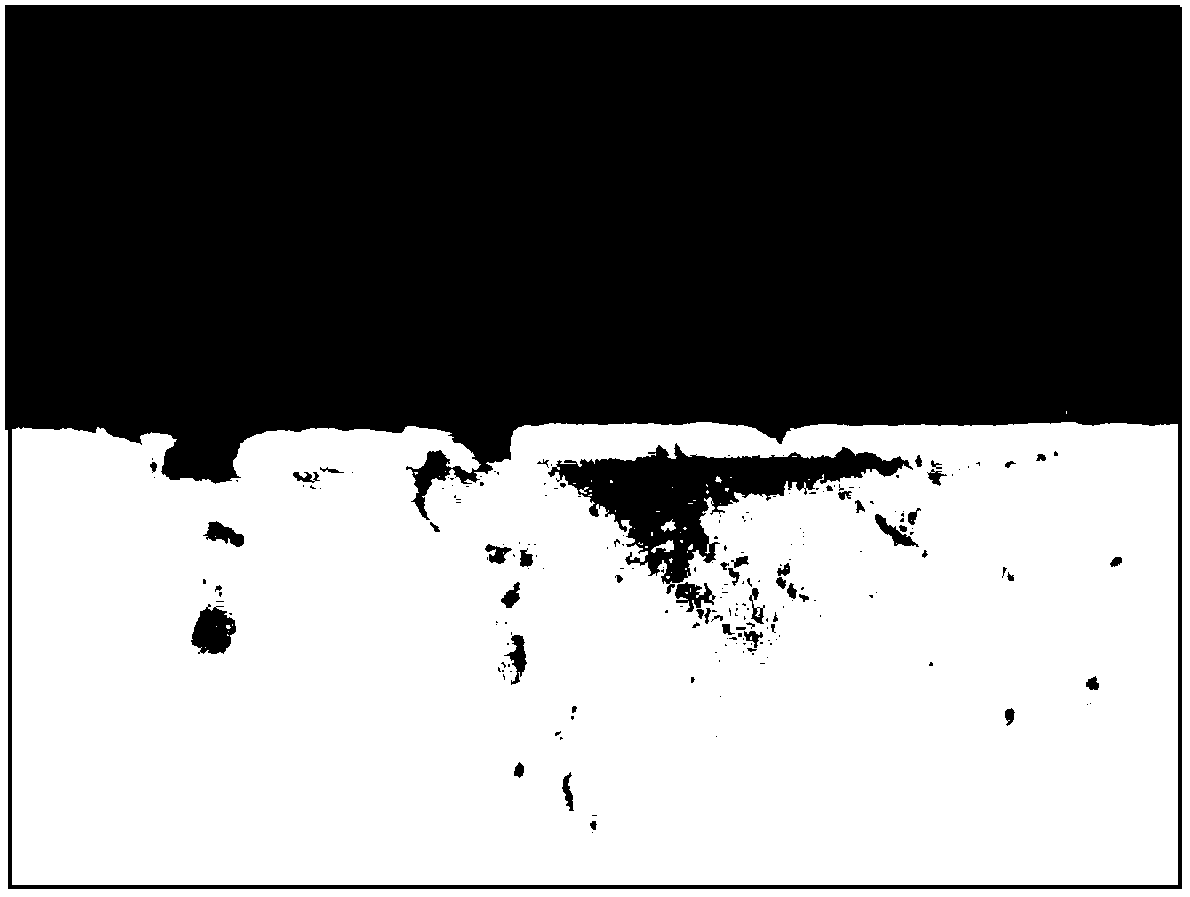

[0030] 3) The workpiece processed in step 2) is subjected to 3D laser laser patterning, and the black peelable paint layer on the surface is removed to expose the lower colored high-gloss paint layer.

[0031] 4) The workpiece treated in step 3) is subjected to PVD arc ion plating of golden titanium nitride, coating conditions: nitrogen gas 150Sccm, current 90A, coating time 3min, vacuum degree 0.1Pa.

[0032] 5) Remove the peelable paint layer on the surface of the workpiece processed in step 4) with 3M adhesive tape.

[0033] 6) The workpiece treated in step 5) is sprayed with a transparent varnish layer, and baked at 70°C for 50 minutes.

Embodiment 2

[0034] Example 2: A seamless sapphire blue and stainless steel shower head

[0035] 1) Spray the pure sapphire blue high-gloss paint layer on the shower head, bake at IR60°C for 5 minutes, and UV energy 800mj / cm 2 .

[0036] 2) The workpiece treated in step 1) is sprayed with a black peelable paint layer, baked at IR60°C for 5min, and UV energy is 1500mj / cm 2 .

[0037] 3) The workpiece processed in step 2) is subjected to 3D laser laser patterning, and the black peelable paint layer on the surface is removed to expose the lower colored high-gloss paint layer.

[0038] 4) The workpiece treated in step 3) is subjected to PVD arc ion plating of stainless steel colored zirconium nitride, coating conditions: nitrogen 50 sccm, argon 100 sccm, current 120A, coating time 2min, vacuum degree 0.2Pa.

[0039] 5) Remove the peelable paint layer on the surface of the workpiece processed in step 4) with 3M adhesive tape.

[0040] 6) The workpiece treated in step 5) is sprayed with a tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com