Rotating device for reaction chamber

A technology of rotating device and reaction chamber, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of unstable dynamic balance of substrate tray, thermal deformation, damage to high sealing performance of reaction chamber, etc. To achieve the effect of reducing thermal deformation effect and reducing error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

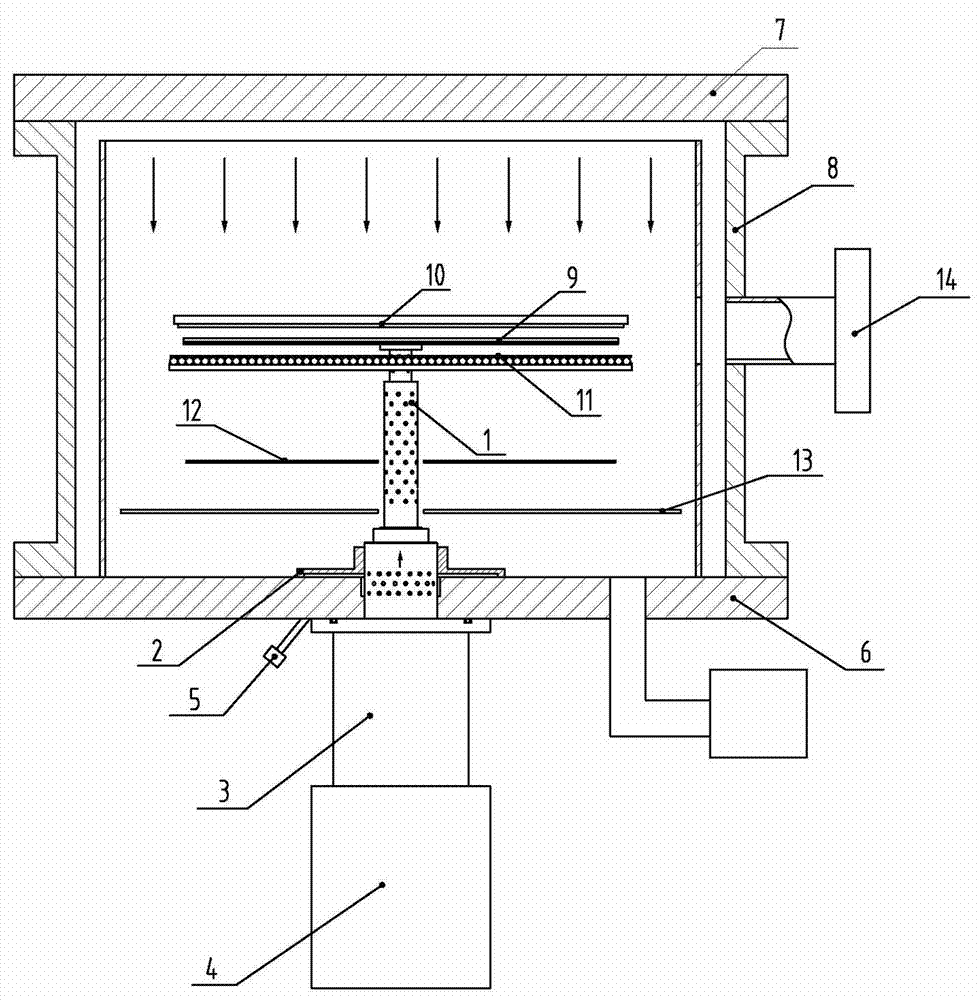

[0017] The invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] Such as figure 1 As shown, the reaction chamber of the MOCVD equipment is composed of a cylinder 8 and upper and lower flanges 7 and 6 . The side of the cylinder is connected with the transfer chamber through a valve 14 . A main shaft 1 is installed on the lower flange 6 and is sealed with the lower flange by a magnetic fluid sealing plate 2, completely separating the interior of the reaction chamber from the outside world. The main shaft 1 is connected with the motor 4 through the magnetic fluid sealing device 3 . The power disk 9 is directly installed on the upper end surface of the main shaft 1, on which the loading disk 10 is freely placed. A heating body 11 and two layers of spaced apart heat shields 12 and 13 are installed below the power disc. Holes are arranged on the heat insulating plate, so that the supporting rods of the heating element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com