Environment-friendly rotary kiln

A rotary kiln and environmental protection technology, applied in the field of rotary kiln, can solve the problems of no space in the kiln body and the weight limit of the kiln body, and achieve the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

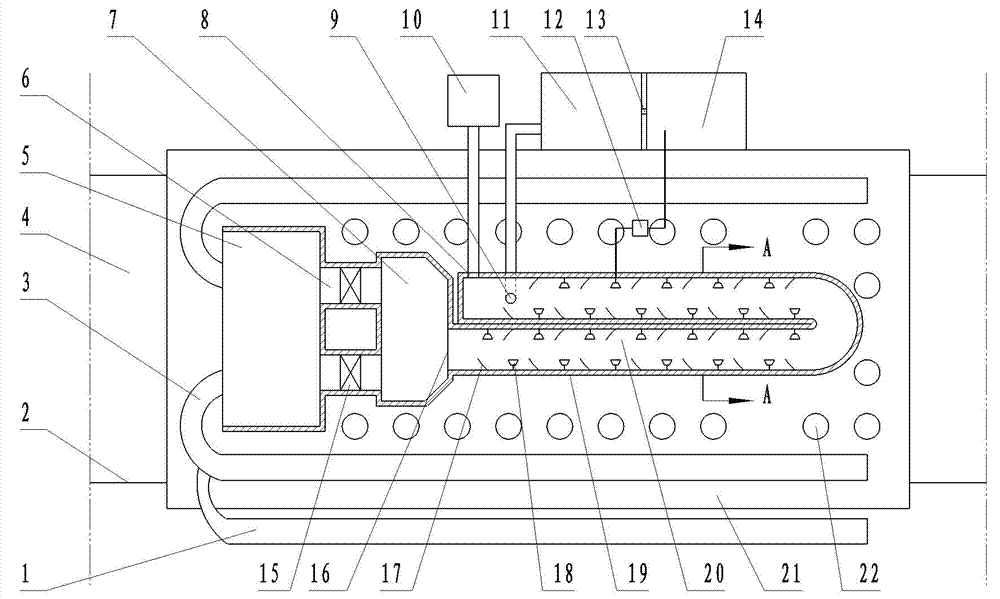

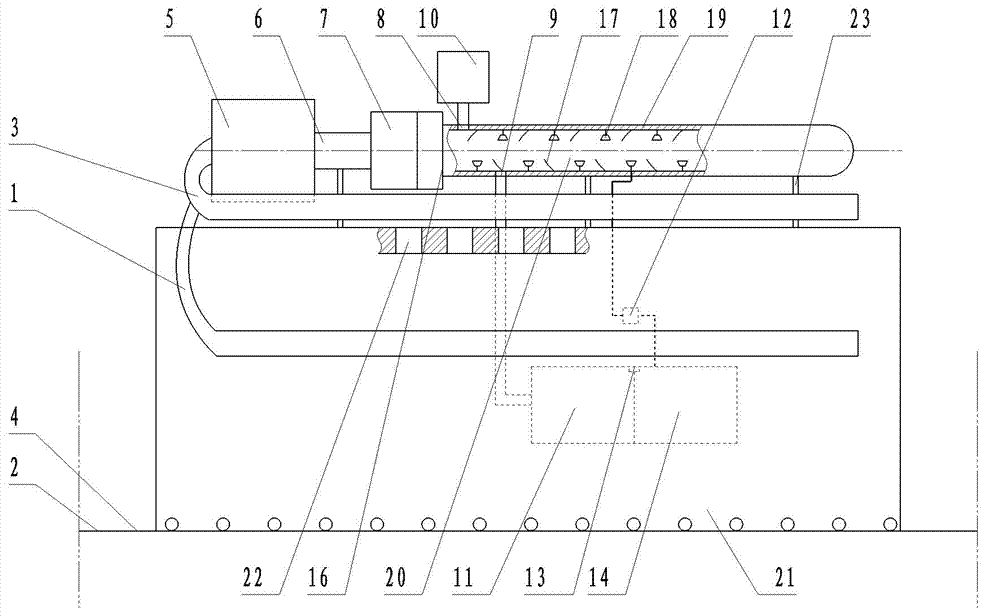

[0023] Embodiment 1: refer to Figure 1~2 , is a structural schematic diagram of Embodiment 1 of the present invention, including a circular track (4) and a kiln body (21) that can move on the track (4), and a desulfurization device and a sewage tank (11) are provided on the kiln body (21) and the slurry pool (14), the desulfurization device includes a desulfurization chamber (20), the desulfurization chamber (20) is a "U"-shaped pipe body, and the pipe body is provided with a flue gas inlet (16), an exhaust port ( 8) and the sewage outlet (9), the inner wall of the pipe body is provided with a nozzle (18) and a baffle (17), the nozzle (18) is connected to the slurry tank (14) through a conduit, and a pump (12) is provided on the conduit, The flue gas inlet (16) of the desulfurization chamber (20) is provided with an air collection box (5) and an air duct (6), and a fan (15) is provided in the air duct (6). The sewage tank (11) is a sedimentation tank and is equipped with The...

Embodiment 2

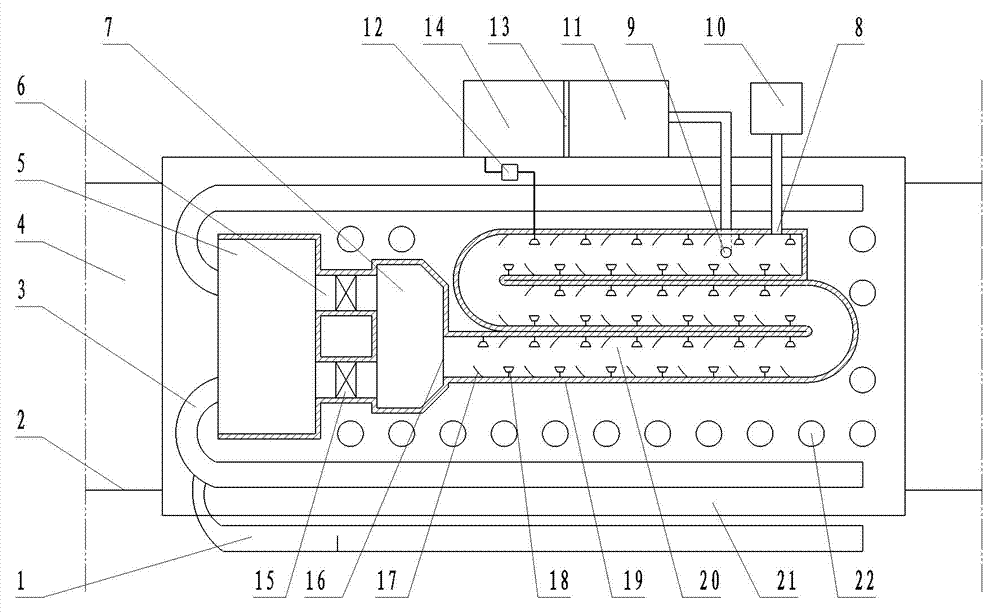

[0025] Embodiment 2, with reference to image 3 , The difference from Example 1 is that the desulfurization chamber (20) is an "S"-shaped pipe body.

Embodiment 3

[0026] Embodiment 3, with reference to Figure 4 , the difference from Example 1 is that the sewage tank (11) is divided into left and right sedimentation tanks, and partitions (11-2) are arranged in the left and right sedimentation tanks, and the sedimentation tanks are divided into "S"-shaped channels , the above-mentioned inlet (11-4) is provided with a valve (11-5).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com