Load-adjustable anti-loosening performance evaluation and detection device for electric power fasteners

A technology for detecting devices and fasteners, which is used in measuring devices, testing of machine/structural components, vibration testing, etc., which can solve the problem of short continuous working time, failure to reflect the dynamic change characteristics of clamping force, and failure to achieve continuous vibration times. Anti-loosening performance evaluation mode and other issues, to achieve the effect of accurate test results, reduced impact, and reduced interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

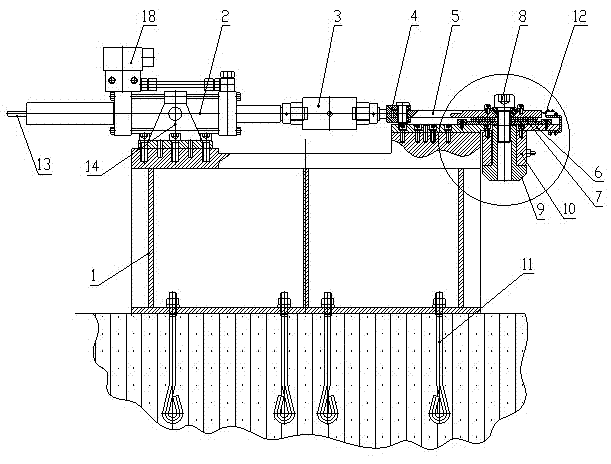

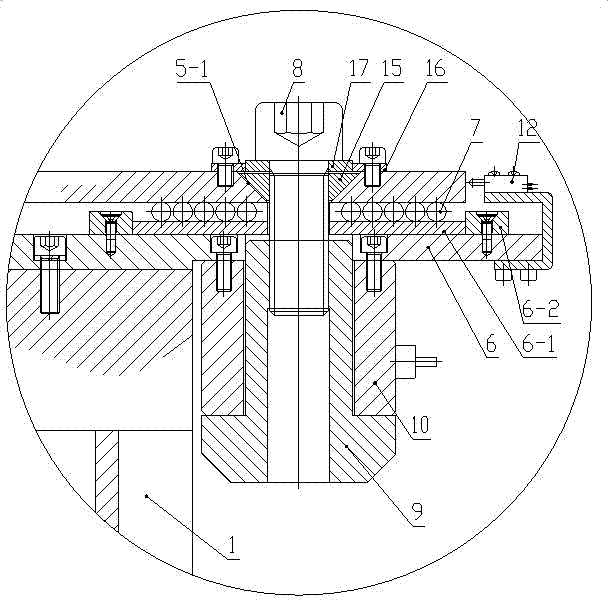

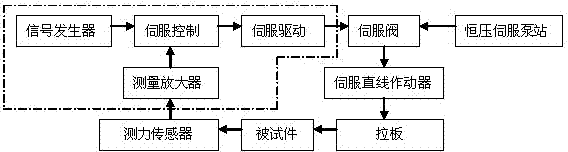

[0034] Example: such as image 3 As shown, M18 bolts are selected for lateral vibration test with sine wave, 5Hz, and load of 10kN. First, fix the "test piece" screw to the "test screw" position, and fix it, and set the initial pre-tightening force (the initial pre-tightening force test is performed by the clamping sensor 10); second, according to the test requirements, in the Select the test mode (mode 1, 2 and 3) on the operation interface, and input parameters such as the waveform, frequency, amplitude and vibration times of the load at the same time. After starting up, the signal generator in the signal loop transmits the control signal to the servo controller, the servo controller drives the servo valve 18, and the servo linear actuator (that is, the servo cylinder 2) drives the piston rod and the connecting seat 4 for mechanical transmission, driving The test screw 8 on the movable pull plate 5 performs lateral reciprocating vibration. The initial pre-tightening force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com